Discover the Amazing Technology Behind PCBs: What is PCB?

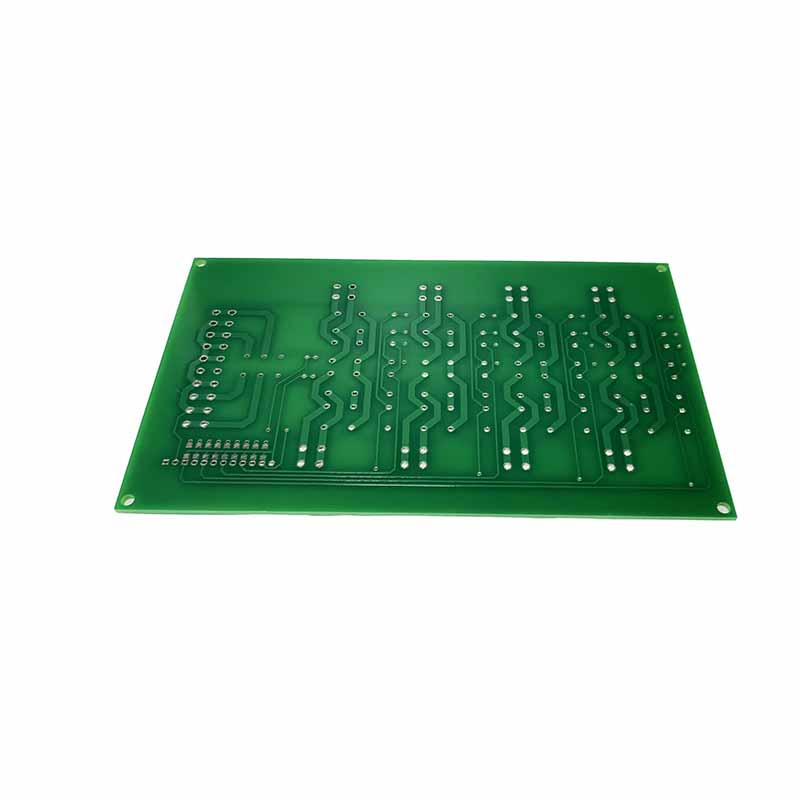

Printed circuit boards (PCBS) are convenient sheets used to accommodate interconnected electrical components in a simple, convenient and economical manner. They are used as physical supports for mounting and connecting different electrical components.

PCBS are made of fiberglass, composite epoxy or any other composite material with a metal-coated surface. They feature etchings made using metals and acids to create circuits through different integrated circuits (ics) and other components on the circuit board. Solder connects the IC and other components to the surface of the circuit board. The copper track in the circuit board reduces the possibility of short circuits, misaligned or misaligned wires.

In this way, all components are securely attached to the board, eliminating the need for complex wiring systems and unnecessary costs. This also simplifies the process of maintaining your PCB according to your needs – no need to deal with a lot of wires.

Are you a hobbyist or an engineer looking to get into the world of PCBs? Or are you just curious about what a PCB is and how it works? Either way, you’ve come to the right place. In this blog, we’ll explore the fascinating technology behind PCBs, from their history to their design and manufacture, and see how they are being used in the modern world. So, what is a PCB? Let’s find out!

What is a PCB?

A printed circuit board (PCB) is a self-contained, interconnected system of conductors and components that are used to create electrical and electronic circuits. PCBs are the backbone of any electronics device, from a simple calculator to a complex laptop. Without PCBs, most of the technology we rely on today would not exist.

The earliest PCBs were developed in the 1950s, and since then, the technology has advanced significantly. Today, PCBs are found in almost every electronic device, from smartphones to smart TVs. In fact, the PCB is the most common type of circuit board in use today.

History of PCBs

The first PCBs were created in the early 1900s, when engineers began experimenting with plastic and paper substrates to create electrical circuits. However, it wasn’t until the 1950s that PCBs became widely used in the electronics industry.

In the early days of PCBs, the process of designing and manufacturing PCBs was extremely laborious and time-consuming. Engineers had to manually etch the circuit patterns into the substrate, a process that could take days or even weeks. This changed in the mid-1960s, when the photolithography process was developed. This allowed engineers to quickly and accurately create circuit patterns on a PCB using a photographic process.

Since then, the technology behind PCBs has continued to evolve. Today, advanced software and automated manufacturing processes make it possible to create complex PCBs with high precision.

Components of a PCB

A PCB consists of two main components: the substrate and the components. The substrate is the base material upon which the circuit is built. It can be made from a variety of materials, including glass-fiber-reinforced epoxy resin, and can come in a variety of sizes and shapes.

The components are the electrical and electronic components that are soldered onto the substrate to form the circuit. These components can include resistors, capacitors, transistors, and integrated circuits.

Types of PCBs

There are several types of PCBs, each designed for a specific purpose.

Single-sided boards are the simplest and most common type of PCB. As the name suggests, they consist of a single layer of substrate with components and conductors on one side.

Double-sided boards are more complex and consist of two layers of substrate with components and conductors on both sides. They are more versatile than single-sided boards, but also more expensive.

Multi-layer boards are the most complex type of PCB and consist of several layers of substrate with components and conductors on multiple layers. They are used for complex, high-speed circuits and are the most expensive type of PCB.

Designing a PCB

Designing a PCB is a complex process that involves several steps. The first step is to create a schematic of the circuit. This schematic is then used to create a layout for the PCB. The layout is used to determine the placement of the components and the routing of the conductors.

Once the layout is finished, it is then used to create the PCB. This is done by etching the conductors and components onto the substrate. The etching process is typically done using a photolithography process, where a circuit pattern is printed onto the substrate using a light-sensitive material.

Finally, the PCB is tested to make sure that all the components and conductors are working properly.

Manufacturing and Testing

Once the PCB is designed, it must be manufactured. This is typically done using a variety of processes, such as injection molding, plating, and soldering. The manufacturing process is highly automated and involves several quality control measures to ensure that the PCBs are up to spec.

Once the PCBs are manufactured, they must be tested to make sure that they are functioning correctly. This is typically done using automated testing equipment, which can detect any faults in the circuit.

PCB Design Software

Designing a PCB requires specialized software. There are several different software packages available, each designed for a specific type of PCB. These software packages can be used to create schematics, layouts, and simulations of the circuit.

The most popular PCB design software is Altium Designer. Altium Designer is a powerful, easy-to-use software package that can be used to create complex PCB designs. It has a wide range of features and tools that make designing PCBs easy and efficient.

Advantages of Using PCBs

PCBs offer several advantages over traditional wiring and component assembly.

The main advantage is that PCBs are much more reliable than traditional wiring and component assembly. Because all of the components and conductors are soldered onto the substrate, there is much less chance of failure due to loose connections or faulty components.

PCBs are also much more cost-effective than traditional wiring and component assembly. Because the components and conductors are soldered onto the substrate, there is no need for additional wiring or soldering, which reduces the cost of manufacture.

Finally, PCBs are much easier to design and manufacture than traditional wiring and component assembly. The use of computer-aided design (CAD) software and automated manufacturing processes makes it easy to create complex and reliable PCBs quickly and efficiently.

Applications of PCBs

PCBs are used in a wide range of applications, from consumer electronics to industrial machinery.

In consumer electronics, PCBs are used to create the circuits that power everything from computers and smartphones to smart TVs and home automation systems. In industrial machinery, PCBs are used to create the control systems that power machinery such as robots and 3D printers.

PCBs are also used in medical devices, automotive systems, and aerospace systems. In all of these applications, PCBs are used to create the sophisticated circuitry that powers modern technology.

Conclusion

PCBs are an essential component of modern technology, from consumer electronics to industrial machinery. They provide the backbone of the circuitry that powers our world, from smartphones to smart TVs.

The technology behind PCBs has come a long way since the 1950s, and today, advanced software and automated manufacturing processes make it possible to create complex and reliable PCBs quickly and efficiently.

So, if you’re looking to get into the world of PCBs, now is the perfect time. With the right tools and knowledge, you can learn to design and manufacture PCBs that can be used in a wide range of applications.

So, what is a PCB? It is an essential component of modern technology that powers our world. From consumer electronics to industrial machinery, PCBs are everywhere, and they are only getting more advanced and versatile. So, if you’re curious to learn more about PCBs, now is the time to dive in!