Customer Reviews

Customer PCB Reviews

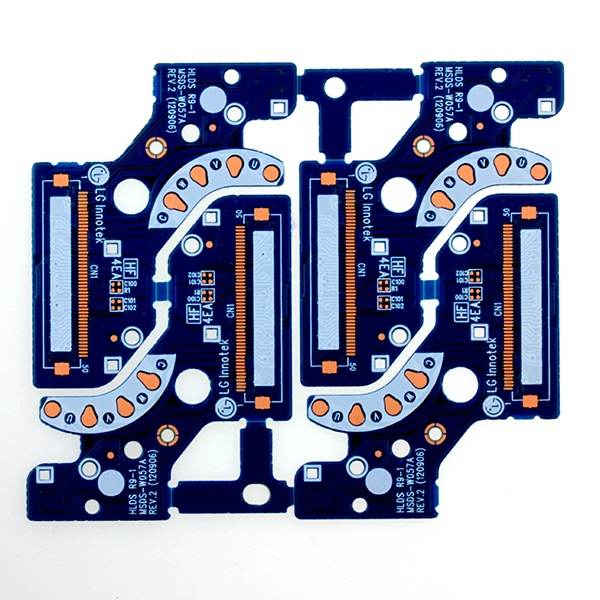

Printed circuit boards (PCBS) are convenient sheets used to accommodate interconnected electrical components in a simple, convenient and economical manner. They are used as physical supports for mounting and connecting different electrical components.

PCBS are made of fiberglass, composite epoxy, or any other composite material with a metal-coated surface. They feature etchings made using metals and acids to create circuits through different integrated circuits (ICS) and other components on the circuit board. Soldier connects the IC and other components to the surface of the circuit board. The copper track in the circuit board reduces the possibility of short circuits, and misaligned or misaligned wires.

can provide you with some general guidelines and best practices for creating a PCB design that meets customer expectations and needs:

Consider the functionality: Ensure that your PCB design meets the functionality requirements of your customer. This involves having a clear understanding of the product or system for which the PCB is being designed.

Keep it simple: Simplicity is key when it comes to PCB design. Customers don’t want complex, confusing designs that are difficult to understand and troubleshoot. Keep the design as simple and straightforward as possible.

Use quality components: The components used in your PCB design play a critical role in the performance and reliability of the final product. Use high-quality components from reputable manufacturers to ensure that your PCB meets customer expectations.

Optimize for manufacturability: Design your PCB with manufacturability in mind. This means considering factors such as assembly and testing, and choosing design elements that will make the manufacturing process more efficient and cost-effective.

Test and validate: Test and validate your PCB design thoroughly before releasing it to customers. This will help you identify and address any potential issues before they become problems for your customers.