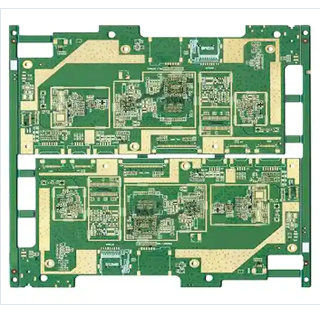

Medical device PCB

- Supplier Type: PCB Fabrication

- Material: KB6061,S1141,S1000,IT180

- Plate thlCkness: 1.6mm

- Minimum aperture: 0.296mm

- Line width: 0.342*0.37mm

- Size: 43.68*38.9mm

- No MOQ or MPQ limited.

- Daily quotes and negotiations.

- Prototypes quotation within 3h.

- Flexible payment options.

- Prototype or mass production order acceptable.

- Project Info

- Specification

Medical supplies PCBs are Printed Circuit Boards (PCBs) designed specifically for medical applications. Implantable medical devices, medical imaging/diagnostics devices, cochlear implants, implanted defibrillators, and Responsive Neurostimulators all contain PCBs (RNS). The Federal Communications Commission (FCC), the US Food and Drug Administration (FDA), the International Standards Organization (ISO), the International Electrotechnical Commission (IEC), and other regulatory agencies must all be followed while developing and manufacturing medical device PCBs. PCBs used in medical devices must also be high-reliability, high-performance, and small in size. They must also be able to enable the usage of specialized components like as lead-free solders, high-temperature components, and conformal coating.

FAQS

1. What are the common features of medical device PCBs?

Answer: Medical supplies PCBs must have qualities such as dependability, performance, and small size. They must also be able to enable the usage of specialized components like as lead-free solders, high-temperature components, and conformal coating.

2. What type of materials are used for medical device PCBs?

Answer: Medical supplies PCBs are often constructed from higher-grade materials suitable for medical applications, such as polyimide and polyamide. They must also meet durability, flame retardancy, and electrical insulation requirements.

3. What types of tests are required for medical device PCBs?

Answer: PCBs used in medical products must be examined to ensure their safety and dependability. All electrical, thermal, shock, vibration, and environmental tests are carried out.

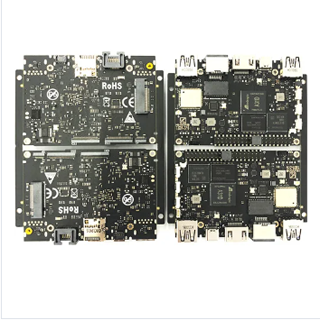

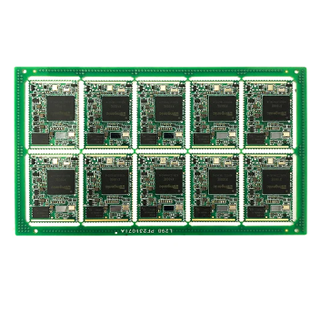

PCB Products show

Our 2 Layer PCB Board Features

Why choose us for PCB assembly services

Economy

We can provide various types of PCB boards and various materials at competitive prices according to customer requirements.

Best Team

No Matter What Kind Of Pcb Board You Want, Our Trained Designers Can Make lt lnAbout 10-12 Working Days. Emplovees Know The lmportance Of Deadlines, AndTheir Goal ls To Give You Top-Notch Results Within A Specified Time Frame.

Best Team

No Matter What Kind Of Pcb Board You Want, Our Trained Designers Can Make lt lnAbout 10-12 Working Days. Emplovees Know The lmportance Of Deadlines, AndTheir Goal ls To Give You Top-Notch Results Within A Specified Time Frame.

Service

Brnon co0p PchaSn To Functes Candackage Finish , We Provid