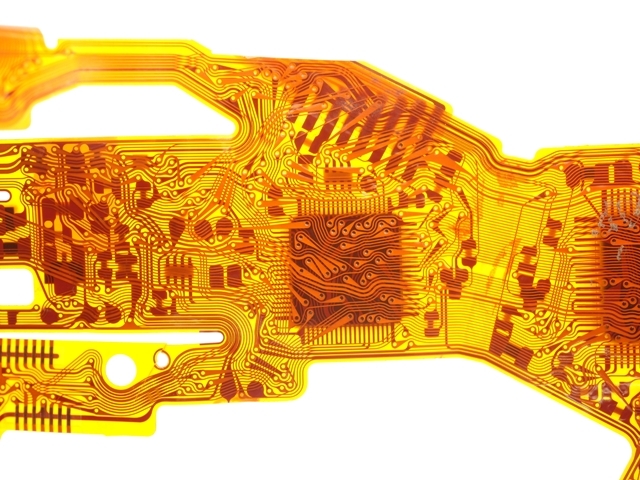

Winow’s Printed Flexible Circuit: Redefining Electronic Possibilities

To meet the growing demand for portable, lightweight electronic devices, the electronic industry constantly seeks innovative solutions. To cater to these evolving needs, Winow New Energy Co., LTD, based in Dongguan, China, has introduced a groundbreaking product: Winow’s Printed Flexible Circuit. This innovative technology is poised to revolutionize the electronic industry by addressing the pressing needs and challenges of the sector. In this blog, we’ll delve into the key requirements and obstacles faced by the electronic industry and how Winow’s Printed Flexible Circuit is positioned to provide solutions.

Winow’s Printed Flexible Circuit: The Needs of the Electronic Industry

The electronic industry plays an indispensable role in modern society, powering everything from smartphones and laptops to medical devices and automotive components. As the demand for electronic products continues to surge, the industry faces a set of critical needs:

1. Miniaturization: Consumers and businesses alike demand smaller and more compact electronic devices that are easy to carry and integrate into various applications. Miniaturization is crucial for wearables, IoT devices, and mobile gadgets.

2. Flexibility: Many applications require electronics to be flexible, conforming to unique shapes and designs. Traditional rigid PCBs (Printed Circuit Boards) often struggle to meet these requirements.

3. Durability: Electronic devices must withstand harsh environmental conditions, including temperature variations, moisture, and physical stress. Ensuring long-term reliability is paramount.

4. Cost-Efficiency: In an increasingly competitive market, manufacturers are under constant pressure to reduce production costs while maintaining high-quality standards.

Winow’s Printed Flexible Circuit: Challenges Faced by the Electronic Industry

Meeting these needs comes with its own set of challenges:

1. Complex Designs: Designing miniaturized and flexible electronic circuits can be intricate, often requiring customized solutions that are both time-consuming and expensive.

2. Material Limitations: Traditional materials may not provide the flexibility and durability needed for certain applications, limiting the industry’s ability to create versatile products.

3. Prototyping and Testing: Developing new electronic circuits can be a costly and time-consuming process. Rapid prototyping and testing are essential to minimize development cycles.

4. Environmental Impact: As the electronic industry continues to grow, there’s a growing concern about its environmental impact, including electronic waste and resource depletion.

Winow’s Printed Flexible Circuit: A Solution to the Challenges

Winow’s Printed Flexible Circuit stands out as a game-changer in the electronic industry. Here’s how it addresses the pressing challenges:

1. Winow’s Printed Flexible Circuit: Miniaturization Made Easy

Winow’s Printed Flexible Circuit technology allows for compact and ultra-thin electronic designs. Its innovative manufacturing process enables intricate, custom shapes, and sizes, making it a preferred choice for applications where size constraints are a concern. This flexibility in design can lead to more ergonomic and aesthetically pleasing products.

2. Winow’s Printed Flexible Circuit: Flexibility Beyond Boundaries

Traditional rigid PCBs can’t match the flexibility of Winow’s Printed Flexible Circuit. Whether it’s a wearable device that conforms to your body or a sensor that needs to fit into tight spaces, this technology provides the flexibility required for a wide range of applications.

3. Winow’s Printed Flexible Circuit: Durability and Longevity

The durable materials used in Winow’s Printed Flexible Circuit ensure the longevity of electronic components, even in challenging environments. This translates to reduced maintenance and replacement costs for industries like aerospace, automotive, and medical devices.

4. Winow’s Printed Flexible Circuit: Cost-Effective Innovation

Winow’s Printed Flexible Circuit technology significantly reduces development costs and time by offering rapid prototyping and testing capabilities. This allows businesses to iterate and fine-tune their designs more efficiently, ultimately reducing time-to-market.

5. Winow’s Printed Flexible Circuit: Environmentally Friendly

Winow’s Printed Flexible Circuit is designed with an eye on sustainability. Its production process is more efficient, and it can be recycled, reducing electronic waste. This eco-friendly approach aligns with the growing concerns about the environmental impact of the electronic industry.

Innovative Solutions: Exploring Ideas to Buy Printed Flexible Circuits from Winow New Energy Co., LTD (Dongguan)

Idea 1: Creating Wearable Electronics

One of the most exciting applications of printed flexible circuits is in the world of wearable electronics. From fitness trackers to smartwatches, these circuits offer flexibility and durability, enabling manufacturers to design sleek, comfortable, and functional wearables. With Winow New Energy Co., LTD’s expertise, you can explore possibilities to create the next generation of wearable technology.

Idea 2: Automotive Innovation

The automotive industry is undergoing a significant transformation with the advent of electric and autonomous vehicles. Printed flexible circuits play a vital role in this transition, as they can be molded to fit into tight spaces, reducing the overall size of electronic components. These circuits can be used in everything from infotainment systems to sensor arrays, helping to make vehicles safer and more efficient.

Idea 3: Revolutionizing Medical Devices

Printed flexible circuits have made significant inroads into the healthcare sector. They are crucial in the development of portable medical devices, diagnostic equipment, and implantable devices. The flexibility of these circuits allows for more comfortable and discreet wearable medical technology while maintaining high precision and reliability.

Idea 4: Aerospace Advancements

The aerospace industry demands lightweight and reliable electronic components. Printed flexible circuits are an ideal choice for such applications, as they are lightweight, durable, and can be customized to fit specific needs. Whether it’s for communication systems, flight control, or navigation equipment, Winow New Energy Co., LTD’s printed flexible circuits are engineered for the most demanding aerospace environments.

Idea 5: IoT Connectivity

In the age of the Internet of Things (IoT), where devices need to communicate seamlessly, printed flexible circuits are invaluable. They can be integrated into sensors and communication modules, enabling efficient data transfer and processing in various IoT applications. As the world becomes more interconnected, these circuits become a cornerstone of modern technology.

Idea 6: Sustainable Electronics

Sustainability is a growing concern in the electronics industry. Printed flexible circuits can be manufactured with eco-friendly materials, reducing electronic waste and contributing to a greener future. Winow New Energy Co., LTD is dedicated to producing environmentally responsible solutions, making them an excellent choice for sustainable electronics projects.

Conclusion

Winow’s Printed Flexible Circuit, offered by Winow New Energy Co., LTD in Dongguan, is poised to redefine the possibilities in the electronic industry. By addressing the pressing needs of miniaturization, flexibility, durability, cost-efficiency, and sustainability, this innovative technology is set to become a cornerstone in the development of future electronic devices. As we embrace a world where electronics seamlessly blend into our daily lives, Winow’s Printed Flexible Circuit paves the way for an exciting future of electronic innovation.