PCBA Manufacturing: Everything You Need to Know

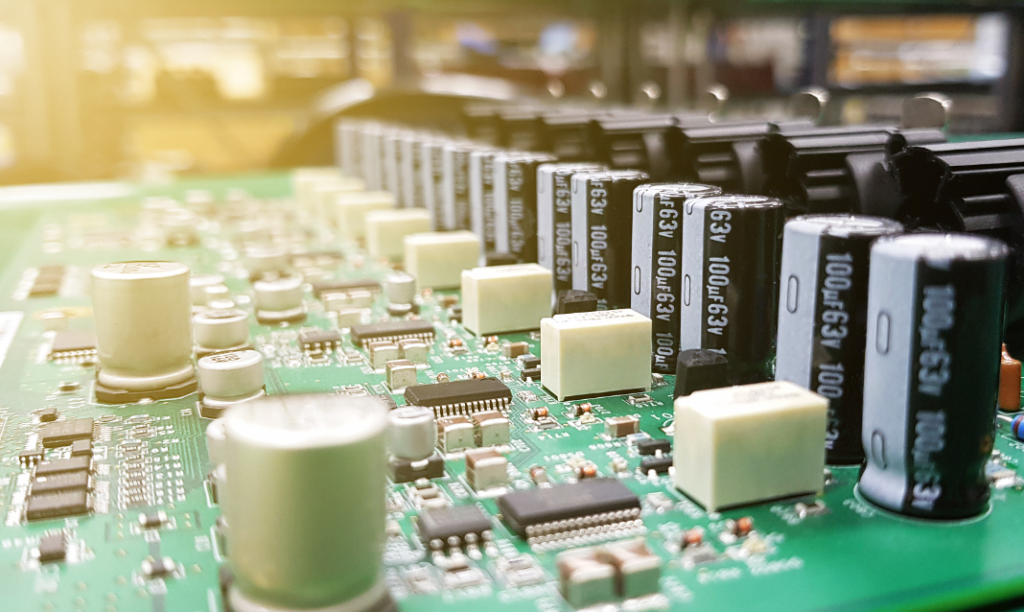

PCBA (Printed Circuit Board Assembly) manufacturing is an essential process for the production of electronic devices. It involves assembling electronic components onto a PCB, which is then integrated into the final product.

Types of PCBA Manufacturing

There are various types of PCBA manufacturing processes, and they include:

1. SMT (Surface Mount Technology) Assembly: This process involves mounting electronic components onto the surface of the PCB using solder paste and a pick-and-place machine.

2. BGA (Ball Grid Array) Assembly: This process involves mounting BGA electronic components onto the surface of the PCB using solder balls and reflow ovens.

3. High-Volume PCB Assembly: This process is used for the large-scale production of PCBAs.

4. Low-Volume PCB Assembly: This process is used for the small-scale production of PCBAs.

5. Prototype PCB Assembly: This process involves the creation of a functional prototype of a PCBA before mass production.

6. Through Hole PCB Assembly: This process involves mounting electronic components onto the PCB by inserting leads through holes in the board and then soldering them to the opposite side.

7. Turnkey PCB Assembly: This process involves the complete manufacturing of a PCB, from sourcing the components to assembling them on the board.

8. Lead-Free PCB Assembly: This process uses lead-free solder to join electronic components to PCBs.

9. DIP (Dual In-line Package) Plug-In Processing: This process involves mounting electronic components onto the PCB by inserting them into sockets that are soldered onto the board.

10. SMT Chip Processing: This process involves mounting SMT electronic components onto the PCB using pick-and-place machines.

Requirements for PCBA Manufacturing

The requirements for PCBA manufacturing depend on the type of assembly process. For SMT assembly, the PCB must be designed for surface mounting, and the manufacturer must have a pick-and-place machine and a reflow oven. For BGA assembly, the manufacturer must have a reflow oven that can accurately control the temperature and a BGA placement machine.

For high-volume PCB assembly, the manufacturer must have the capacity to produce large quantities of PCBAs, while for low-volume PCB assembly, the manufacturer must be able to produce small quantities of PCBAs cost-effectively. For prototype PCB assembly, the manufacturer must have a quick turnaround time and the ability to create functional prototypes.

Target Audience and Benefits of PCBA Manufacturing

The target audience for PCBA manufacturing includes electronic device manufacturers, hobbyists, and startups. Electronic device manufacturers require high-quality, cost-effective PCBAs for their products. Hobbyists and startups require PCBAs for their DIY electronic projects and prototypes. By choosing a reliable PCBA manufacturer like Winow New Energy, these audiences can benefit from cost-effective and high-quality PCBAs that meet their specific needs.

Winow New Energy and PCBA Manufacturing

Winow New Energy is a leading PCBA manufacturer that offers a wide range of services, including SMT assembly, BGA assembly, high-volume PCB assembly, low-volume PCB assembly, prototype PCB assembly, through hole PCB assembly, turnkey PCB assembly, lead-free PCB assembly, DIP plug-in processing, and SMT chip processing. They have state-of-the-art facilities and a highly skilled team that can meet the needs of various industries. They also offer customized PCBA solutions to meet specific requirements.

The Latest Trends in PCBA Manufacturing: Automation, AI, and IoT Integration

One of the latest trends in PCBA manufacturing is automation. With the help of automation, PCB manufacturers can increase productivity, reduce errors, and lower labor costs. Automation also enables them to produce complex PCB designs more efficiently. Winow New Energy implements automation in their PCB manufacturing processes to ensure high quality and efficiency.

Another trend is the integration of AI (Artificial Intelligence) in PCBA manufacturing. AI can be used to identify defects in PCB designs and help manufacturers optimize their processes for better efficiency. It can also assist with predictive maintenance to prevent equipment breakdowns and reduce downtime. Winow New Energy is constantly exploring ways to integrate AI into its manufacturing processes to improve the overall quality and efficiency of its services.

IoT (Internet of Things) integration is another trend in PCBA manufacturing that has gained momentum in recent years. IoT enables manufacturers to gather data from machines and processes to optimize manufacturing processes further. It also enables real-time monitoring of the production line, allowing manufacturers to identify and address issues before they become bigger problems. Winow New Energy has integrated IoT technology into its

manufacturing processes to increase efficiency and reduce costs.

Quality Control Measures Key to Success in PCBA Manufacturing Industry

PCBA (Printed Circuit Board Assembly) manufacturing has undergone significant changes in recent years due to technological advancements. As a result, PCB manufacturers are constantly adapting to the latest trends in automation, AI, and IoT integration to keep up with the demands of the market.

In the PCB assembly and manufacturing industry, quality control measures are crucial to ensuring success. One company that understands this is Winow New Energy, a leading PCB manufacturer in China.

To ensure their PCB products meet the highest quality standards, Winow employs various quality control measures, including strict inspections of raw materials and components, comprehensive testing of finished products, and adherence to industry standards and regulations.

PCBA Manufacturing Industry Embraces Sustainability and Social Responsibility

Winow New Energy is a leading PCBA manufacturer in China that offers a one-stop shop for PCB design, manufacturing, and assembly. Their state-of-the-art SMT and through-hole equipment, along with certified technicians, allow them to provide high-quality PCBs with no minimum quantity requirement and no setup fees. Winow New Energy specializes in 1-20 layer PTH board, flexible board, rigid-flex board, HDI board, and aluminum-based board.

Winow New Energy serves various industries, including medical, transportation, aerospace, and consumer electronics. They offer customized PCBA solutions for any industry, size, or location. Winow New Energy’s pursuit of quality service is evident in its no MOQ or MPQ limit policy, flexible payment options, and daily quotes and negotiations.

Winow’s PCBs serve clients from various industries, including medical, transportation, telecommunications, aerospace, and consumer electronics. Their PCBs are used in a variety of equipment, from medical machines like pH meters and CT scanners to aerospace remote sensing systems and aviation radar.

Conclusion

Winow New Energy’s commitment to quality control measures in PCBA manufacturing ensures that its products meet the highest standards of quality, reliability, and efficiency. Their implementation of a comprehensive quality management system, quality assurance, process control, testing and inspection, and continuous improvement provides several benefits to their target audience, including high-quality products, consistent quality, on-time delivery, and reduced costs. For businesses and individuals relying on PCBA products, Winow New Energy is the ideal partner for their needs.