PCB Printed Circuit Board Design: Techniques for Success

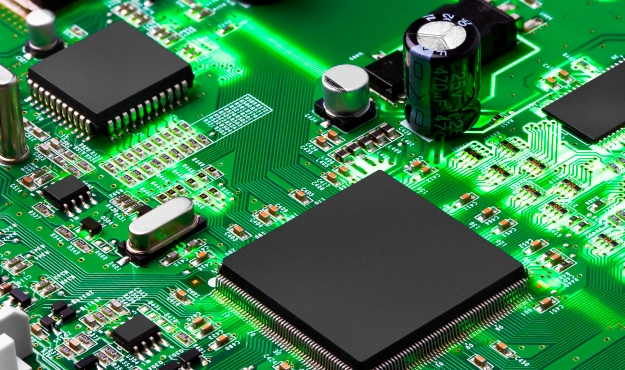

Today’s digital age is powered by printed circuit boards, the unsung heroes behind our electronic devices. PCB Printed Circuit Board is at the heart of almost every electronic gadget, making them an integral part of our daily lives. But behind these seemingly unassuming boards lies a complex world of design and manufacturing.

PCB Printed Circuit Board: Understanding PCBs

PCB Printed Circuit Board: Printed Circuit Board Basics

A Printed Circuit Board, commonly known as a PCB, is a flat board made of non-conductive material (usually fiberglass) with a layer of copper on one or both sides. PCBs serve as the framework for connecting and supporting various electronic components, such as integrated circuits, capacitors, resistors, and connectors. They provide a secure and organized platform for electrical connections, enhancing the reliability and functionality of electronic devices.

PCB Printed Circuit Board: Types of PCBs

PCBs come in various types, each designed for specific applications. Common types include:

1. Single-Sided PCBs: These boards have conductive material on only one side and are often used in simple applications.

2. Double-Sided PCBs: These have conductive material on both sides, allowing for more complex circuitry.

3. Multi-Layer PCBs: These consist of several layers of conductive material separated by insulating layers, accommodating intricate and compact designs.

PCB Printed Circuit Board: How to Buy PCB Printed Circuit Boards from Winow

Purchasing PCBs from Winow is a straightforward process:

1. Contact Winow: Reach out to Winow New Energy Co., LTD by sending an email to info@winowpcba.com. Describe your PCB requirements and request a free quotation.

2. Sample Evaluation: Upon receiving the quotation, you can request samples to evaluate the quality and suitability of the PCBs for your project.

3. Place Your Order: If you are satisfied with the samples and the provided quotation, you can proceed to place your order with Winow.

4. Receive Outstanding Service: Throughout the purchasing process, Winow ensures that you receive top-notch customer service and expert guidance.

Design for Manufacturing: The Key to Efficient PCB Production

Design for Manufacturing Principle 1: Minimize Complexity

The first principle of Design for Manufacturing in PCB Printed Circuit Board design is to minimize complexity. Simplicity is your best friend when it comes to designing PCBs for efficient manufacturing. Complex designs can lead to longer manufacturing times and higher costs. By keeping your design straightforward, you can reduce the risk of errors and streamline the production process.

Design for Manufacturing Principle 2: Component Placement Matters

The placement of components on your PCB can greatly impact manufacturing efficiency. Group related components together and consider the order of assembly. By optimizing component placement, you can reduce the need for complex tooling and fixtures, making the manufacturing process smoother and cost-effective.

Design for Manufacturing Principle 3: Proper Clearances and Tolerances

Precision is vital in PCB manufacturing. Ensure that you adhere to the appropriate clearances and tolerances. This not only ensures the correct functionality of your PCB but also minimizes manufacturing errors. Always work closely with your PCB manufacturer to understand their specific requirements.

PCB Printed Circuit Board: Troubleshooting Guides

1. Overcoming Signal Integrity Issues

One of the most common problems in PCB design is signal integrity. A high-speed digital signal can become distorted, leading to data errors and functionality issues. To address this challenge, designers should consider factors like trace length, impedance control, and proper ground and power plane design. Implementing advanced tools and consulting with experts can be valuable in achieving optimal signal integrity.

2. Resolving Thermal Management Challenges

Thermal issues can significantly affect PCB performance and lifespan. Overheating components can lead to failure, reduced efficiency, and safety hazards. Proper heat dissipation strategies, including heat sinks, thermal vias, and well-placed components, are crucial to prevent overheating. Collaborating with a supplier like Winow New Energy, known for its expertise in thermal management, can be advantageous.

PCB Printed Circuit Board: Prototyping and Manufacturing Tips

Prototyping Tip 1: Start with a Thorough Schematic

Before diving into the PCB layout, create a detailed schematic. This serves as the foundation for your design. It helps you identify potential issues early in the design process, saving time and resources down the line.

Prototyping Tip 2: Test and Validate

Don’t skip the testing phase. Prototyping is the ideal time to verify your design’s functionality. Fixing issues at this stage is far less expensive and time-consuming than doing so in large-scale manufacturing.

Manufacturing Tip 1: Choose the Right PCB Manufacturer

Selecting the right PCB Printed Circuit Board manufacturer is crucial. Ensure they have a strong track record, offer the capabilities you need, and can handle the volume you require. Winow New Energy Co., LTD in Dongguan is a reputable supplier known for its commitment to quality and efficiency.

Manufacturing Tip 2: Optimize for Efficiency

Work closely with your PCB manufacturer to optimize your design for large-scale production. Consider panelization to increase throughput, minimize waste, and lower production costs. Additionally, maintain open communication with your manufacturer throughout the process to address any issues or modifications promptly.

Meet the Trusted PCB Supplier: Winow New Energy Co., LTD (Dongguan)

Winow New Energy Co., LTD, located in Dongguan, is a reliable PCB supplier with a strong reputation for delivering high-quality products. They specialize in producing a wide range of PCBs, from single-layer to multilayer boards, and offer services tailored to various industries, including automotive, aerospace, and consumer electronics. With a commitment to quality and efficiency, Winow New Energy Co., LTD is an excellent choice for all your PCB needs.

PCB Printed Circuit Board: Why Choose Winow?

Here are some compelling reasons to consider Winow for your PCB needs:

1. Free Quotation: Winow offers free quotations for your PCB requirements, ensuring transparency and helping you make informed decisions.

2. Sample Availability: They provide samples, allowing you to evaluate the quality and compatibility of their PCBs with your specific project.

3. Top-Notch Service: Winow places a strong emphasis on customer service, assisting you throughout the ordering process and addressing any questions or concerns promptly.

4. Design Expertise: Their team of experts can provide design assistance to ensure that your PCB meets the required specifications and functions optimally.

Conclusion

Understanding the principles of PCB Printed Circuit Board Design for Manufacturing, along with following best practices for prototyping and large-scale manufacturing, can significantly impact the efficiency and cost-effectiveness of PCB production. By partnering with a reputable supplier like Winow New Energy Co., LTD, you can ensure that your PCB designs are brought to life with the highest standards of quality and reliability. So, whether you’re designing the latest smartphone or a cutting-edge medical device, remember that a well-designed PCB is the backbone of your innovation.