Top 5 PCB Manufacturing Companies to Consider for Your Projects

When it comes to electronic device production, one crucial element is the Printed Circuit Board (PCB). A PCB serves as the backbone of any electronic device, connecting and supporting various components. Finding the right PCB manufacturing company is essential to ensure the smooth functioning and reliability of your projects. In this blog, we will explore the top 5 PCB manufacturing companies that you should consider for your upcoming projects. These companies have established a reputation for their quality, efficiency, and customer satisfaction.

Winow New Energy Co., Ltd (Dongguan)

One of the leading names in the PCB manufacturing industry is Winow New Energy Co., Ltd (Dongguan). With decades of experience, Winow has become synonymous with quality PCBs. They offer a wide range of services, including PCB production, design, and assembly. Whether you need single-sided, double-sided, or multi-layered PCBs, Winow has the expertise to meet your requirements.

Other Top PCB Manufacturing Companies

Apart from Winow New Energy Co., Ltd (Dongguan), here are four other top PCB manufacturing companies that you should consider for your electronic projects:

1. Jabil Inc.

Jabil Inc. provides end-to-end electronic manufacturing services, including PCB manufacturing, design, and assembly. They offer a range of PCB products, from simple single-sided PCBs to complex multi-layered PCBs for various industries.

2. Flex Ltd.

Flex Ltd. is a global leader in PCB manufacturing with a presence in over 30 countries. They offer a wide range of PCB solutions, including flex and rigid-flex PCBs, backplanes, and high-density interconnects.

3. Sanmina Corporation

Sanmina Corporation is a leading PCB manufacturer that offers a range of services, from quick-turn prototypes to volume production. They specialize in high-density, high-speed, and high-layer count PCBs for various industries, including aerospace, defense, and medical.

4. TTM Technologies, Inc.

TTM Technologies, Inc. is a global PCB manufacturer that specializes in custom PCB solutions for various industries, including automotive, aerospace, and networking/communications. They offer a range of PCB products, including HDI PCBs, flex and rigid-flex PCBs, and high-frequency PCBs.

PCB manufacturing companies often encounter common challenges that can impact the development process. Addressing these challenges effectively is essential to ensure smooth operations. The following are some common challenges and the corresponding solutions companies like Winow New Energy Co., Ltd (Dongguan) implement:

1. Design Optimization

Efficient design optimization is crucial to ensure functionality and cost-effectiveness. PCB manufacturing companies employ skilled engineers who collaborate closely with clients to enhance the design and optimize it for manufacturing. This includes maximizing component placement, minimizing signal interference, and reducing the size of the PCB.

2. Material Selection

Choosing the right materials is vital for the performance and longevity of the PCB. Manufacturers work closely with clients to understand their requirements and provide guidance on material selection. This includes considering factors such as thermal conductivity, dielectric constant, and cost-efficiency.

3. Sourcing Quality Components

The availability and quality of components can significantly impact PCB production. PCB manufacturing companies establish strong relationships with reputable component suppliers to ensure the availability of high-quality components. They also conduct thorough quality control checks to identify and address potential issues.

A Behind-the-Scenes Look at PCB Manufacturing Companies: Processes and Equipment

Successful PCB manufacturing companies employ state-of-the-art processes and equipment to ensure the highest quality and efficiency. Here is a glimpse into the behind-the-scenes processes and equipment utilized by these companies:

1. PCB Fabrication

PCB fabrication involves several stages, including designing the PCB layout, producing the copper artwork, applying etching techniques to remove unwanted copper, and applying a protective solder mask. Advanced equipment, such as computerized numerical control (CNC) machines and laser drilling machines, is used to achieve precision and accuracy in the fabrication process.

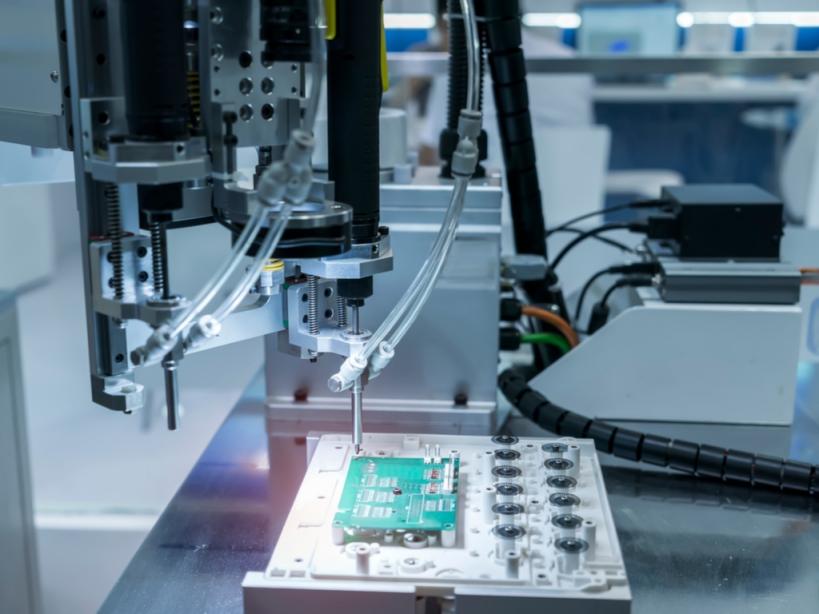

2. Assembly and Soldering

The assembly and soldering stage involves mounting and soldering the electronic components onto the PCB. This process is performed using highly automated and precise equipment, such as pick-and-place machines and reflow ovens. These machines ensure accurate component placement and proper soldering, resulting in reliable and durable PCBs.

PCB Manufacturing Companies: Accelerating Development Cycles and Time-to-Market

In the highly competitive electronics industry, accelerating development cycles and reducing time-to-market are critical for success. PCB manufacturing companies contribute to this by employing various strategies:

1. Prototyping Services

Offering prototyping services allows clients to test and refine their designs before proceeding to full-scale production. PCB manufacturing companies provide quick-turn prototyping services, enabling clients to iterate and make necessary modifications swiftly.

2. Design-for-Manufacturability (DFM) Analysis

DFM analysis ensures that designs are manufacturable and cost-effective. PCB manufacturing companies leverage their expertise to conduct comprehensive DFM analyses, identifying potential design issues early on. This minimizes the need for redesign and reduces development time.

Why Choose Winow New Energy Co., Ltd (Dongguan)?

Winow distinguishes itself from other PCB manufacturing companies through its commitment to quality, reliability, and customer satisfaction. Here are some compelling reasons why you should consider Winow for your PCB manufacturing needs:

1. Advanced Manufacturing Technology

Winow utilizes state-of-the-art manufacturing technology to produce high-quality PCBs. They understand the importance of precision and efficiency in the production process, ensuring that each PCB meets the highest industry standards.

2. Extensive Product Range

Whether you need PCBs for consumer electronics, automotive applications, medical devices, or industrial equipment, Winow has a diverse range of PCB products to cater to your specific project requirements. Their comprehensive product range ensures that you can find the perfect PCB solution for your application.

3. Customization and Flexibility

Winow understands that every project is unique, and they offer customization options to tailor their PCBs according to your specific needs. Their team of experts works closely with clients to understand their requirements and provide the most suitable manufacturing solutions.

4. Quality Control and Assurance

Winow has a rigorous quality control and assurance process in place to ensure that every PCB that leaves its facility is of the highest standard. From the initial design review to the final inspection, every step is meticulously carried out to minimize errors and defects.

5. Competitive Pricing

While Winow maintains high-quality standards, they also offer competitive pricing for their PCB manufacturing services. This combination of quality and affordability makes them an attractive choice for businesses of all sizes.

Conclusion

Choosing the right PCB manufacturing company is crucial for the success of your projects. The top 5 PCB manufacturing companies mentioned in this blog, including Winow New Energy Co., Ltd (Dongguan), have a proven track record and offer reliable solutions for all your PCB needs. By partnering with a reputable PCB manufacturer, you can ensure the quality, reliability, and efficiency of your electronic devices. So, whether you are a small startup or a large enterprise, consider these PCB manufacturing companies to take your projects to the next level.