PCB Fabrication

- 10+ Year Experience on PCB Fabrication Services

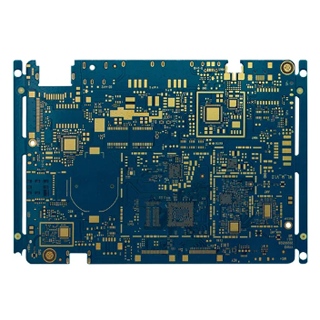

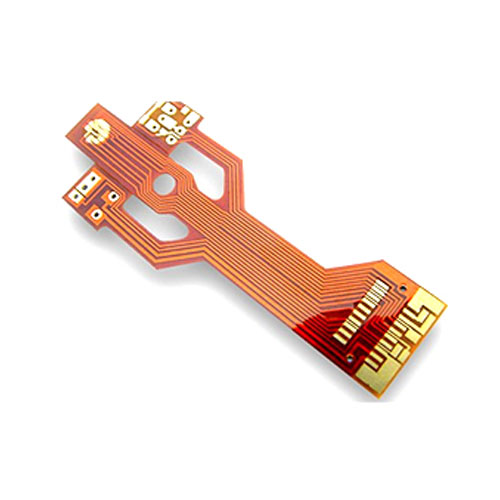

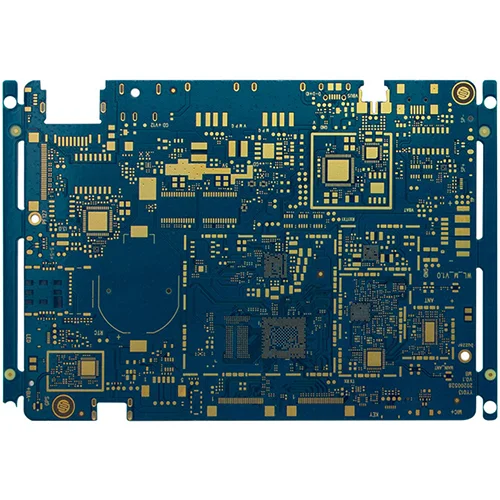

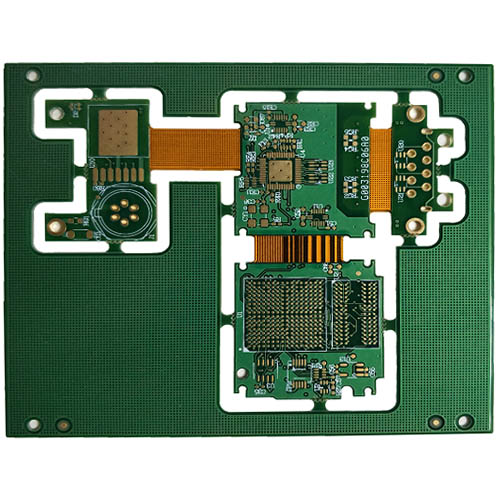

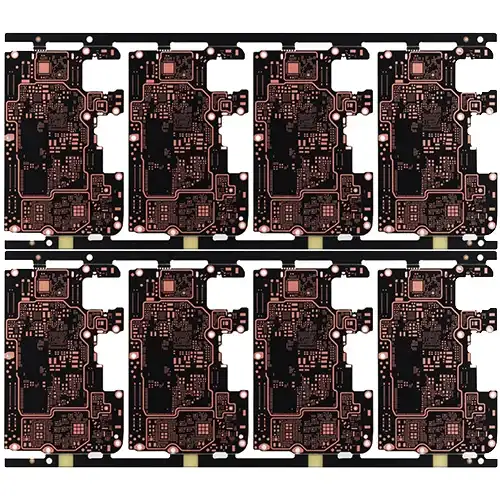

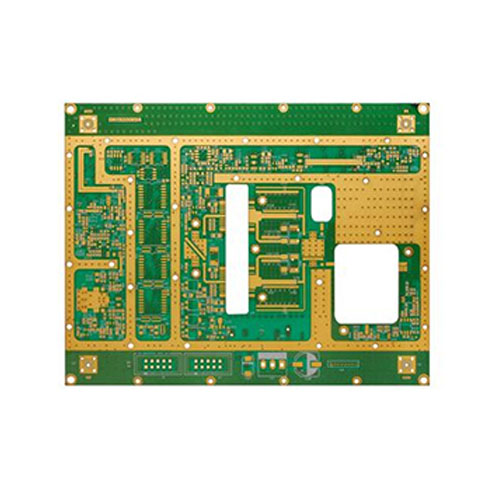

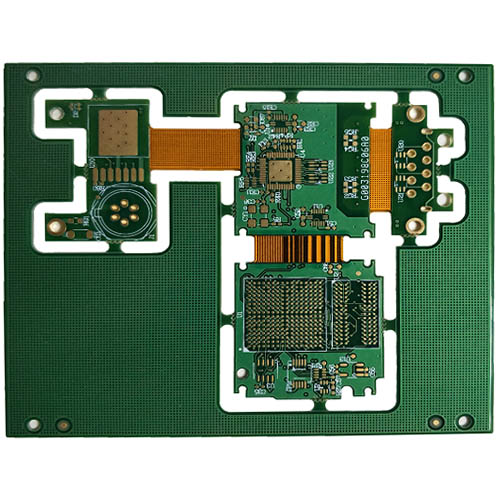

1-40layer board from rigid PCB, rigid-flex PCB, and flexible PCB

-

Quick turn order in 24h for prototype PCB.

-

7/24 live sales and engineering support

-

No minimum order quantity, even 1 piece.

-

Working time to follow your local time.

-

Sufficient raw materials in stock including KB, Shengyi, Rogers, Arlon, Nelco

10 Years Experience in PCB Fabrication

As a one-stop PCB fabrication company with more than 10 years of experience in China, we can manufacture the PCB boards you need by doing the one-stop process including design, feasibility analysis, manufacturing, assembly and testing according to your idea or schematic diagram (Design).

Ship As Fast As 24 Hours

- Turn times as short as 24 hours

- 1 to 100,000 units

- Class II Inspection standard and Class III Inspection available

- 100% on-time guarantee

- DFM support

- Lead free (RoHS) options

- SMT and thru-hole capabilities

- All SMT machine placed

- AOI (Automated Optical Inspection)

- Lead-free RoHS Certification and ITAR compliance screen available

-

Program Design

-

PCB Fabrication Capability

-

PCB main process requirements information

-

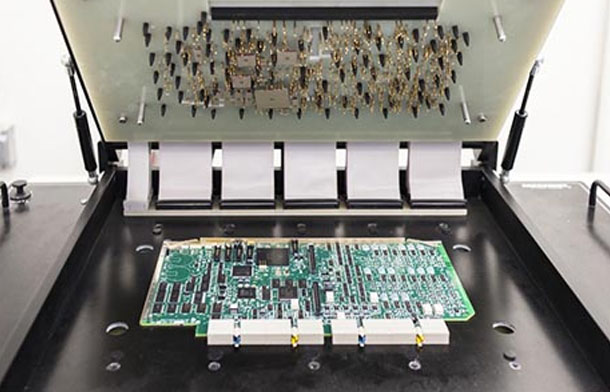

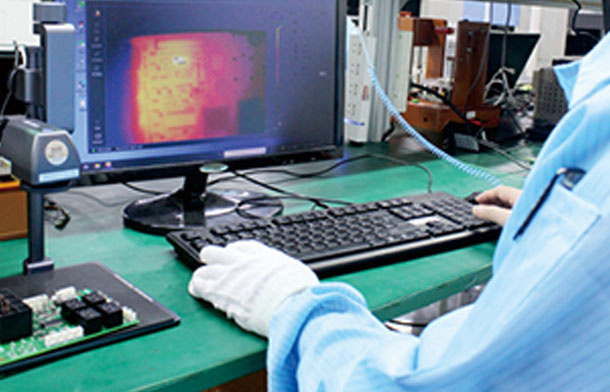

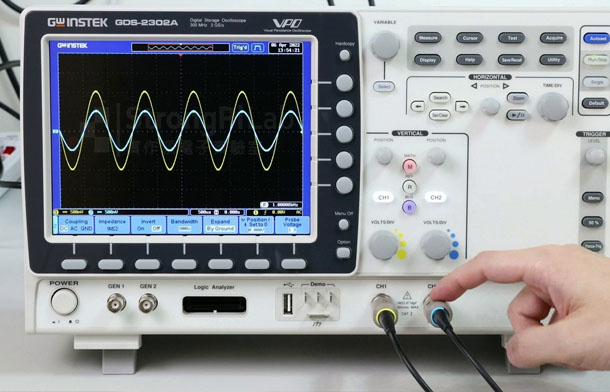

Testing Equipment

From component procurement to functional testing and package completion, we provide one-stop services for all types of PCBs.

PCB Fabrication Capability

| PCB Layers | 1~64 Layer |

| Quality Grade | IPC Class 2|IPC Class 3 |

| Laminate/Base material | FR-4|S1141|High Tg|PTFE|Ceramic PCB|Polyimide|S1000-2|IT180A|Isola-FR408HR|FR406|Isola 370 HR|Rogers|Taconic|Arlon|Halogen Free, etc. |

| Brand of Laminate | ITEQ|Shengyi|Nanya|Isola|TUC|SYL|Arlon|Nelco|Taconic|Hitachi|Rogers, etc. |

| High Temperature Material | Normal Tg: Shengyi S1141|KB6160|Huazhen H140(not suitable for lead-free process ) Middle Tg: For HDI、multilayers: SY S1000H|ITEQIT158|HuazhengH150|TU-662|SY S1150G|HuazhengH150HF|H160HF; High Tg: For thick copper、high layer: SY S1000-2|ITEQIT180A|HuazhengH170|ISOLA: FR408R|370HR|TU-752|SY S1165 |

| High Frequency Circuit Board Material | Rogers|Arlon|Taconic|SY SCGA-500|S7136|HuazhengH5000 |

| High Speed PCB Material | SY S7439|TU-862HF|TU-872SLK|ISOLA: I-Speed, I-Tera@MT40|Huazheng:H175|H180|H380 |

| Ink | Taiyo INK (Japan)|KUANGSHUN(China)|RONGDA(China)|Coates Screen(UK)|S.M Materials(Taiwan, China) |

| Heat Conductivity for Alu. Boards | Boards 1.0 |

| Chemical | Rohm&Haas (US)|Atotech (Germany)|Umicore (Germany) |

| PCB Type and Services | Prototype PCB|Rigid PCB|Flexible PCB(FPC)|Rigid-Flex PCB|HDI PCB|High Tg PCB|BGA PCB|Impedance Control PCB|IMS PCB(LED PCB Board, Aluminum PCB, Metal Core PCB)|Multilayer PCB|PCBA(PCB Assembly Service) |

| Max Board Size | 609 * 889 mm |

| Board Thickness | 0.1~8.0mm |

| Board Thickness Tolerance | ±0.1mm / ±10% |

| Min base copper thickness | Outer layer:1/3oz (12um) ~10oz|Inner layer:1/2oz~6oz |

| Max finished copperthickness | 6 OZ |

| Min Mechanical Drilling Hole Size | 6mil(0.15mm) |

| Min Laser Drilling Hole Size | 3mil(0.075mm) |

| Min CNC Drilling Hole Size | 0.15mm |

| Hole Wall Roughness(Max) | 1.5mil |

| Min trace width/spacing(Inner Layer) | 2/2mil(Outer layer:1/3oz,Inner layer:1/2oz) (H/H OZ base copper) |

| Min trace width/spacing(Outer Layer) | 2.5/2.5mil (H/H OZ base copper) |

| Min spacing between hole to inner layer conductor | 6mil |

| Min spacing between hole to outer layer conductor | 6mil |

| Min annular ring for via | 3mil |

| Min annular ring for component hole | Min annular ring for component hole |

| Min BGA diameter | 8mil |

| Min BGA pitch | 0.4mm |

| Min Finished hole size | 0.15mm(CNC)|0.1mm(Laser) |

| Half Hole Diameter | Minimum Half hole Diameter: 1mm, Half hole is a special technology, so half hole diameter should be greater than 1mm. |

| Hole Wall Copper Thickness (Thinnest) | ≥0.71mil |

PCB (Printed Circuit Boards) is the printed circuit board, as the carrier for the electrical interconnection of electronic components, and is also the most important electronic component in the electronics industry. Its performance directly determines the stability and stability of the control circuit part. reliability. As a professional EMS electronic manufacturing service provider with many years of experience, Goto Electronic Technology can provide customers with high-quality, high-reliability circuit board manufacturing services of different types, different materials, and different processes.

| Quality Standard | IPC-A-600H |

| Structural process | Rigid board, soft board, soft and rigid board |

| layers | 1-32 floors |

| Plate type | CEM3,FR-4,Rogers,Teflon,High Tg |

| biggest size | 850mm*520mm |

| Board Thickness Range | 0.2mm - 8mm |

| Copper Thickness Range | 1/3oz – 15oz |

| minimum aperture | 0.15mm |

| Minimum line width and line spacing | 0.05/0.05mm |

| Impedance Control Accuracy | ±5% |

| Surface Technology | Lead-free HASL, anti-oxidation OSP, immersion gold ENIG, gold plating/electrogold, immersion tin, immersion silver |

| Warpage | 0.5% |

PCB Fabrication

Testing Procedures

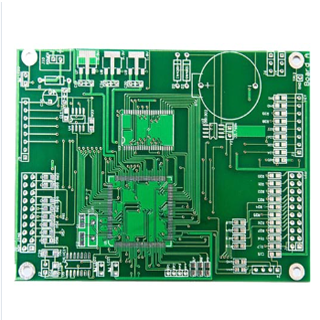

PCB (printed circuit board) fabrication is the process of turning a design file into a physical circuit board. It consists of several steps, including:

- Creating a schematic diagram of the circuit and laying out the components on a PCB layout software is the first step in designing the PCB layout.

- The PCB layout is then used to generate a photomask, which is a transparency with the circuit’s pattern etched onto it.

- Printing the photomask onto a blank PCB: Using photolithography, the photomask is used to transfer the circuit pattern onto a blank PCB.

- Etching the PCB: The PCB is then immersed in an etching solution, which removes any excess copper from the board, leaving only the circuit traces.

- Drilling the PCB: Small holes are then drilled into the PCB to allow for component insertion.

- Finishing: To protect the PCB from the environment, it is then coated with a finish.

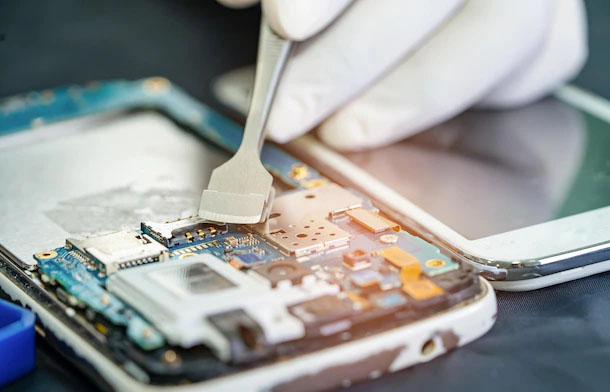

- Component assembly: The components are then soldered onto the PCB to complete the circuit.

Bring you better PCB products

Circuit Board Fabrication and PCB Assembly Turnkey Services

PCB Fabrication FAQ

What is PCB Fabrication?

Benefits of PCB Fabrication

PCB manufacturing process

PCB fabrication materials

Tools and software for PCB fabrication

Design considerations for PCB fabrication

Common PCB fabrication mistakes

Tips for successful PCB fabrication

PCB fabrication services

Why Choose Us?

WINOW has been providing high-quality PCBs with fast turnaround times and high customer satisfaction since 2018. We are one of China's largest and most skilled board manufacturers. Winow PCB is a PCB manufacturer and PCB assembly service provider based in China with over ten years of industry experience. We'll assist you in getting your projects up and running by providing quick quotes and one-stop manufacturing services.

-

Prototype orders are processed within 24 hours.

-

Some PCB prototypes and small-batch manufacturing typically take 5-7 working days.

-

A 48-hour lead time for small batch production and some PCB prototypes.