PCB BOX Building

A PCB Box Building, also referred to as a PCB enclosure, is a type of enclosure used to protect and house electronic circuits, most commonly printed circuit boards (PCBs). It can be made of many different materials, including plastic, metal, or a combination of the two.

Your Qualified PCB Box Building Partner

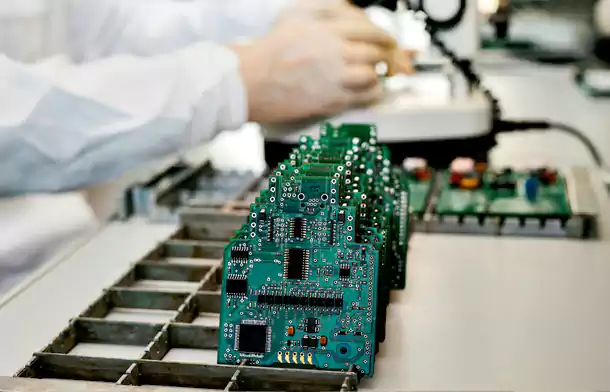

Compatible with guidelines of ISO9001:2015,IATF16949:2016, RoHS and UL (E511658) certificates, we offer turnkey and custom PCB Box Building products and services, including:

We can provide:

- PCB Box Building

- Cable Assembly

- PCB Fabrication

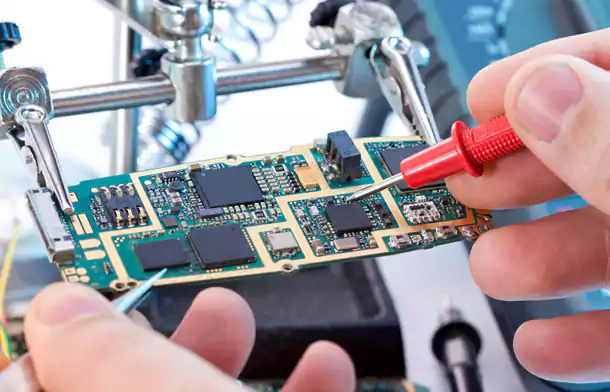

- PCBA Testing:In-Circuit, Functional, Final and Burn-In Test

- Printed Circuit Board Assembly

- Hard Finding Components Sourcing

- PCB Layout(PCB Design)

Testing Procedures

A PCB Box Building, also known as a PCB enclosure, is a type of enclosure used to protect and house electronic circuits, typically printed circuit boards (PCBs). It can be made from a variety of materials, including pcba,plastic, metal, or a combination of them.

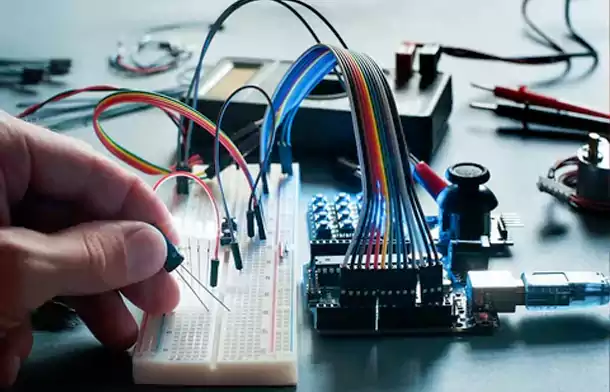

There are several steps involved in the construction of a PCB box building:

- Enclosure design entails creating a 3D model of the enclosure and determining its size, shape, and material.

- Fabricating the enclosure entails making the physical enclosure using a variety of techniques such as injection molding, stamping, or machining.

- Assembling the enclosure entails attaching any necessary components to the enclosure, such as screws, hinges, or latches.

- Finishing the enclosure: This may include applying a finish to the enclosure, such as painting or powder coating, to improve its appearance and durability.

- Placing the PCB inside the enclosure and connecting it to any necessary components, such as connectors or switches, is what this step entails.

Bring you better PCBA products

Circuit Board Fabrication and PCB Box Building Turnkey Services

Frequently asked questions

What materials are commonly used to make PCB Box Building?

What factors should be considered when designing a PCB box Building?

How is a bare PCB assemblied?

How is a PCB box building finished?

What are some common issues that can arise when building a PCB box?

Why Choose Us?

Suga Tech has been providing high-quality PCB Box Building with faster delivery times and high customer satisfaction since 2002. As a leading manufacturer of PCBA in China, we have a wealth of experience.

-

Orders for prototypes are processed within 24 hours.

-

The Typical lead time for some PCBA prototypes and small batch production is 5-7 working days.

-

Shorter lead time Some PCB prototypes and small batch production can be completed in 48 hours.