PCB Assembly in California: A Comprehensive Guide

PCB assembly is a crucial process in the manufacturing of electronic devices. It involves the fabrication of printed circuit boards (PCBs) and the assembly of electronic components onto them. California is a hub for technology and innovation, and as such, PCB assembly in California is a thriving industry.

There are numerous PCB assembly companies in California that offer a wide range of services to meet the needs of various industries. These companies use state-of-the-art equipment and employ experienced technicians to ensure that their clients receive high-quality PCB assemblies. Some of the services offered by these companies include PCB design, PCB fabrication, component sourcing, PCB assembly, and testing.

PCB assembly in California is not only limited to the manufacturing of electronic devices but also extends to the aerospace, medical, and automotive industries. These industries require PCB assemblies that meet stringent quality standards and have high reliability. As such, PCB assembly companies in California have the expertise and capabilities to cater to the specific needs of these industries.

Overview of PCB Assembly Services in California

California is home to a thriving electronics industry, with many companies offering PCB assembly services. These services range from prototype development to full-scale production runs, and cover a wide variety of industries, including aerospace, medical, and automotive.

One of the key advantages of PCB assembly services in California is the ability to work with a wide range of materials and technologies. This includes traditional through-hole components, as well as surface mount devices (SMDs), ball grid arrays (BGAs), and other advanced packaging technologies.

Another advantage of PCB assembly services in California is the ability to offer quick turnaround times. Many companies offer expedited services for urgent projects, and can often turn around prototypes in as little as 24 hours.

In addition to traditional PCB assembly services, many California-based companies also offer value-added services such as design assistance, testing and inspection, and supply chain management. These services can help customers streamline their operations and reduce costs.

Overall, PCB assembly services in California offer a wide range of options for customers looking to develop and produce high-quality electronic products. With a focus on innovation and customer satisfaction, these companies are well positioned to meet the needs of a rapidly evolving industry.

PCB Design and Prototyping in California

Design Services

California is home to a number of PCB design services that offer a range of design options. These services can help clients create a custom PCB design that meets their specific needs. Some of the design services offered in California include schematic capture, PCB layout, and design verification.

Schematic capture involves creating a graphical representation of a circuit that shows how components are connected. PCB layout involves placing components and routing traces on a PCB. Design verification involves testing the design to ensure it meets the required specifications.

Prototyping Techniques

Prototyping is an important step in the PCB assembly process. California offers various prototyping techniques that can help clients create a functional prototype of their PCB design. Some of the prototyping techniques include:

- Breadboarding: This involves building a prototype on a breadboard, which is a board used for prototyping electronics. Breadboarding is a quick and easy way to create a prototype, but it is not suitable for complex designs.

- PCB milling: This involves using a milling machine to create a prototype PCB. PCB milling is a more accurate and precise method of prototyping, but it is also more expensive.

- 3D printing: This involves using a 3D printer to create a prototype PCB. 3D printing is a relatively new technology that is becoming more popular in the prototyping process. It is a fast and cost-effective way to create a prototype, but it may not be suitable for all designs.

In conclusion, California offers a range of PCB design and prototyping services that can help clients create a custom PCB design that meets their specific needs. Clients can choose from various design services and prototyping techniques to create a functional prototype of their design.

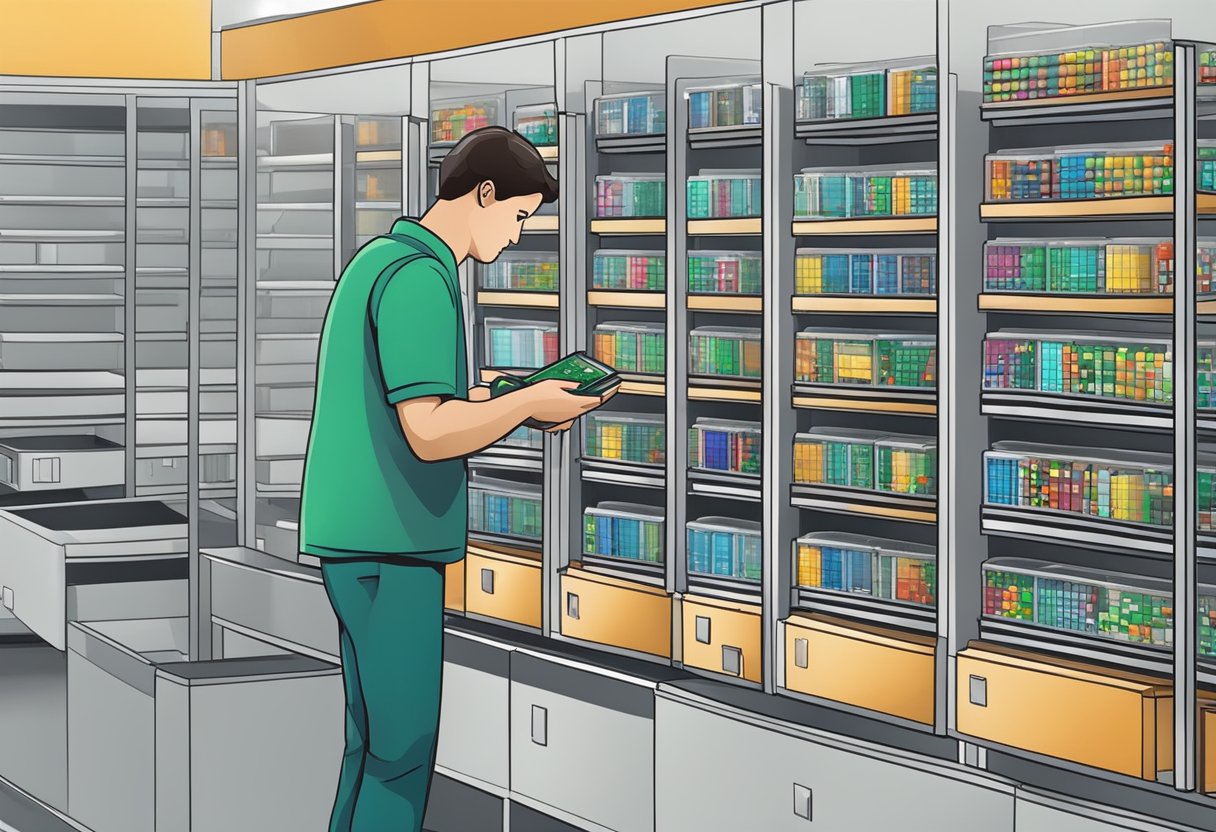

Components Sourcing for PCB Assembly

When it comes to PCB assembly, sourcing components is a crucial step in the process. The quality and reliability of the components used can directly impact the performance and durability of the final product. In California, there are various options available for sourcing components, including local suppliers and global supply chain integration.

Local Component Suppliers

California has a thriving electronics industry, and there are many local suppliers who specialize in providing components for PCB assembly. These suppliers offer a range of options, from off-the-shelf components to custom-made parts. Some popular local suppliers include:

- Digi-Key Electronics: Based in Thief River Falls, Minnesota, Digi-Key Electronics is one of the largest electronic component distributors in the world. They offer a wide range of components, including semiconductors, connectors, and passive components.

- Arrow Electronics: With headquarters in Centennial, Colorado, Arrow Electronics is another global distributor of electronic components. They offer a variety of products and services, including design engineering, supply chain management, and logistics solutions.

- Future Electronics: Based in Montreal, Quebec, Future Electronics is a global distributor of electronic components with a strong presence in California. They offer a range of products, including semiconductors, passives, and electromechanical components.

Local suppliers can offer several advantages, including faster delivery times, lower shipping costs, and better customer service. Additionally, working with a local supplier can help reduce the risk of counterfeit components, which can be a major concern when sourcing components from overseas.

Global Supply Chain Integration

While local suppliers can be a great option for sourcing components, there are also benefits to integrating with the global supply chain. Global suppliers can offer access to a wider range of components, often at lower prices. Additionally, global suppliers can provide support for sourcing hard-to-find components and managing supply chain logistics.

Some popular global suppliers include:

- Mouser Electronics: Based in Mansfield, Texas, Mouser Electronics is a global distributor of electronic components with a strong presence in California. They offer a range of products, including semiconductors, passives, and electromechanical components.

- Avnet: With headquarters in Phoenix, Arizona, Avnet is a global technology solutions provider that offers a range of products and services, including electronic components, enterprise computing solutions, and embedded systems.

- RS Components: Based in Corby, United Kingdom, RS Components is a global distributor of electronic components with a strong presence in California. They offer a wide range of products, including semiconductors, passives, and electromechanical components.

Global suppliers can offer several advantages, including access to a wider range of components, lower prices, and support for managing supply chain logistics. However, working with global suppliers can also present challenges, such as longer delivery times and higher shipping costs.

In conclusion, when it comes to sourcing components for PCB assembly in California, there are many options available. Local suppliers can offer faster delivery times and better customer service, while global suppliers can provide access to a wider range of components and lower prices. Ultimately, the choice of supplier will depend on the specific needs of the project and the priorities of the customer.

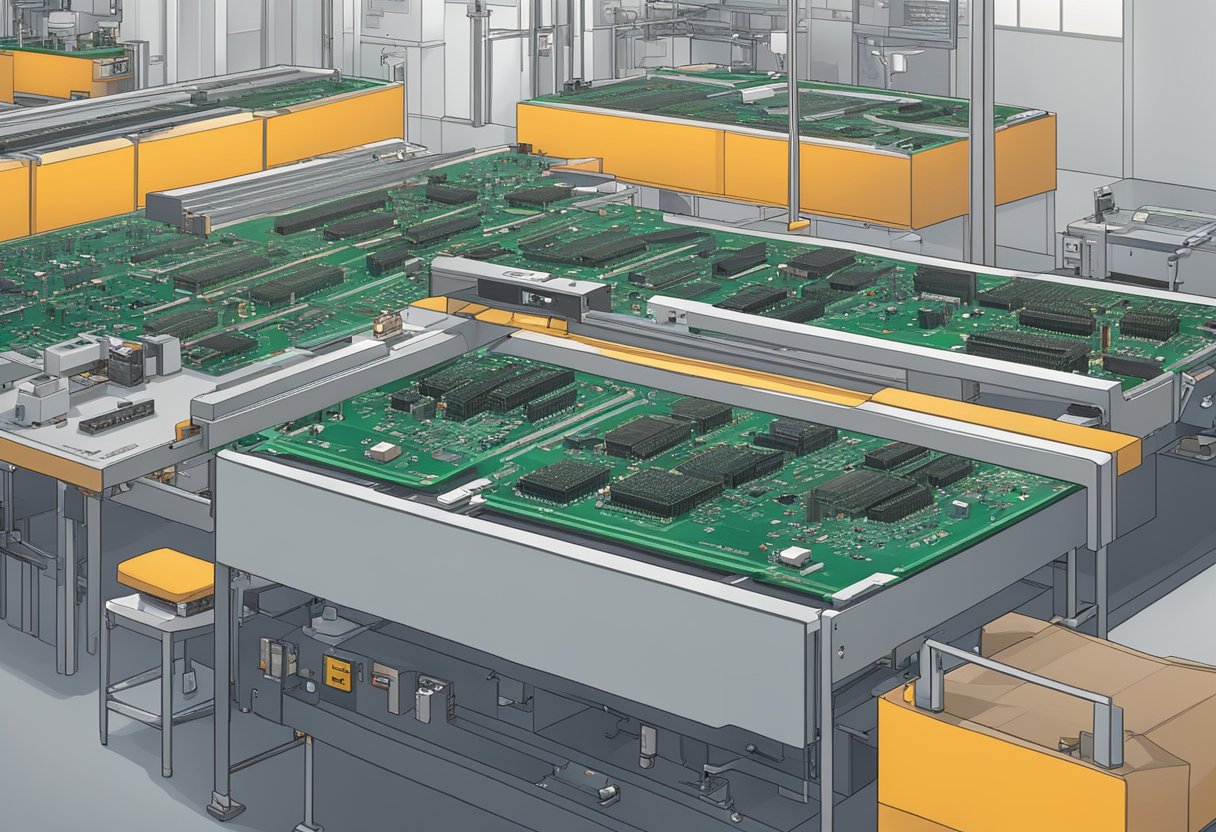

PCB Assembly Manufacturing Processes

PCB assembly is a complex process that involves a series of manufacturing processes. These processes are designed to ensure that the final product is of high quality and meets the required specifications. In this section, we will discuss the three main PCB assembly manufacturing processes.

Surface Mount Technology (SMT)

Surface mount technology (SMT) is a popular PCB assembly manufacturing process that involves mounting electronic components directly onto the surface of the PCB. This process is known for its high level of accuracy and speed. SMT is widely used in the electronics industry due to its ability to produce high-density PCBs with small components.

During the SMT process, solder paste is applied to the surface of the PCB. The components are then placed on top of the solder paste and heated to a high temperature. The solder paste melts and forms a strong bond between the component and the PCB. SMT is suitable for both small and large volume production runs.

Through-Hole Technology (THT)

Through-hole technology (THT) is an older PCB assembly manufacturing process that involves mounting electronic components on the opposite side of the PCB. This process is known for its durability and strength. THT is commonly used in applications where the PCB needs to withstand high levels of stress and vibration.

During the THT process, holes are drilled into the PCB. The components are then inserted into the holes and soldered to the opposite side of the PCB. THT is suitable for low to medium volume production runs.

Mixed Technology Assembly

Mixed technology assembly is a combination of SMT and THT processes. This process is used when a PCB requires both SMT and THT components. Mixed technology assembly is a complex process that requires a high level of expertise and precision.

During the mixed technology assembly process, SMT components are mounted on the surface of the PCB while THT components are mounted on the opposite side of the PCB. Mixed technology assembly is suitable for both small and large volume production runs.

In conclusion, PCB assembly manufacturing processes are critical in ensuring that the final product is of high quality and meets the required specifications. SMT, THT, and mixed technology assembly are the three main PCB assembly manufacturing processes. Each process has its advantages and disadvantages, and the choice of process depends on the specific requirements of the PCB.

Quality Assurance and Testing

When it comes to PCB assembly in California, quality assurance and testing are crucial steps to ensure that the final product meets the highest standards. Here are some of the key methods used in the industry:

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a critical part of the quality control process. AOI machines use advanced cameras and software to inspect the PCBs for defects, such as missing components, incorrect polarity, and soldering issues. This process is much faster and more accurate than manual inspection, which can be prone to human error.

Functional Testing Protocols

Functional testing protocols are used to ensure that the PCBs meet the required specifications and perform as expected. This involves testing the functionality of each component on the board, as well as the overall system. Functional testing can be done manually or with the help of specialized equipment, depending on the complexity of the PCB.

Environmental Stress Testing

Environmental stress testing is used to evaluate the durability and reliability of the PCBs under various conditions, such as temperature, humidity, and vibration. This testing helps to identify any weaknesses in the design or manufacturing process that could lead to failure in the field.

Overall, PCB assembly in California is a highly regulated and quality-controlled process. By using advanced technology and rigorous testing protocols, manufacturers can ensure that the final product is of the highest quality and meets the needs of their customers.