Take Your Project to the Next Level with LED PCB Assembly!

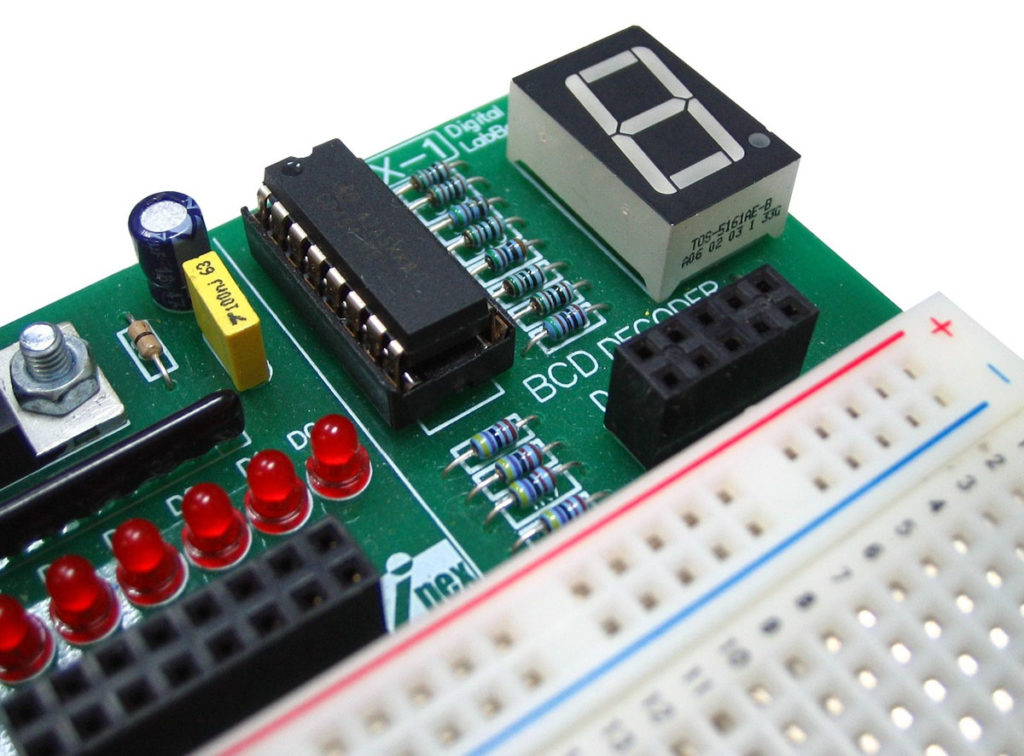

LED PCB assembly involves the mounting and soldering of various components onto a printed circuit board (PCB) to create electronic systems and devices that use light-emitting diodes (LEDs). The specific components and assembly process will depend on the design of the PCB and the requirements of the end application.

Here are some general steps that may be involved in assembling an LED PCB:

- Prepare the PCB: This may include cleaning the PCB, applying solder mask, and printing or etching the circuit design onto the board.

- Mount components: The components of the LED PCB, such as transistors, diodes, capacitors, and resistors, are mounted onto the PCB using soldering or other mechanical fastening techniques. The LEDs themselves are also mounted onto the PCB.

- Solder components: The components are soldered to the PCB using a soldering iron or machine to create permanent electrical connections between the components and the PCB.

- Test and inspect: The assembled LED PCB is tested to ensure that it is functioning properly and meets the required specifications. Any defects or issues are identified and corrected.

LED PCB assembly requires a high level of precision and attention to detail, as the PCBs are used in a wide range of applications and must operate reliably. It also requires a thorough understanding of the relevant technical and regulatory standards, as well as experience with specialized materials and processes that may be required for LED applications.

Are you looking for a way to take your project to the next level? LED PCB Assembly is the answer! This technology has revolutionized the way we create and manufacture printed circuit boards, making them faster, more efficient, and more reliable. In this blog, we’ll discuss all you need to know about LED PCB Assembly, from its many benefits to the process and design considerations. Read on to learn more!

What is LED PCB Assembly?

LED PCB Assembly is the process of mounting light-emitting diodes (LEDs) onto printed circuit boards (PCBs). This is done by attaching the LEDs to the board with soldering and other materials, creating a single, integrated circuit. This process can be used to create a wide range of products, from simple circuits used in everyday items to complex devices used in industry.

LEDs are small, efficient, and powerful, making them ideal for a variety of applications. LEDs are also available in a wide range of colors, making them perfect for adding visual interest to a project. By using LED PCB Assembly, you can create a much more visually appealing product without sacrificing efficiency or reliability.

Benefits of LED PCB Assembly

LED PCB Assembly offers a number of benefits, making it a great choice for any project. Some of the most notable benefits include:

- Improved reliability: LED PCB Assembly creates a reliable circuit that is less likely to fail due to environmental conditions or other factors. This improved reliability can be especially important in projects that require precise timing or need to be able to withstand harsh conditions.

- Reduced costs: LED PCB Assembly is typically more cost-effective than traditional PCB assembly methods, making it an attractive option for projects that need to be completed quickly or on a tight budget.

- Increased efficiency: LED PCB Assembly is much faster than other methods of PCB assembly, making it a great option for projects that need to be completed quickly.

- Improved aesthetics: LEDs are small and come in a wide range of colors, making them ideal for adding visual interest to a project.

LED PCB Assembly Statistics

LED PCB Assembly has become increasingly popular in recent years, and the numbers show why. According to a recent survey, the global market for LED PCB Assembly is expected to reach $21.87 billion by 2027, representing an impressive compound annual growth rate of 10.2%. This growth is due in part to the increased demand for LED-based solutions in a wide range of industries, from medical to automotive.

In addition, the demand for LED PCB Assembly is expected to be driven by the growth of the Internet of Things (IoT). As more and more devices become connected, the need for LED PCB Assembly solutions will continue to grow. This growth is expected to create a number of exciting opportunities for engineers and manufacturers alike.

LED PCB Assembly Process

The LED PCB Assembly process typically involves several steps, including the following:

- Designing the circuit: The first step of the process is to design the circuit. This involves creating a schematic and laying out the components on the PCB.

- Preparing the board: Once the circuit has been designed, the board needs to be prepared for assembly. This typically involves soldering and other processes to ensure that the components are properly connected.

- Preparing the LEDs: Once the board is ready, the LEDs need to be prepared. This involves attaching the LED to the board with soldering and other materials.

- Assembling the board: The last step of the process is to assemble the board. This involves placing the components onto the board and soldering them together to create a single, integrated circuit.

Selecting the Right LED PCB Assembly Supplier

When it comes to selecting an LED PCB Assembly supplier, there are a few key factors to consider. First, make sure that the supplier you choose has a good reputation and is reliable. It’s also important to make sure that the supplier is able to provide the services you need and offers competitive prices. Lastly, make sure that the supplier is able to meet your timeline and budget.

Design Considerations for LED PCB Assembly

When designing a circuit for LED PCB Assembly, there are a few key considerations to keep in mind. First, make sure that the components are properly laid out on the board. This will ensure that the circuit is efficient and reliable. Second, make sure that the components are properly connected to the board. This will ensure that the circuit is able to function properly. Lastly, make sure that the LEDs are properly attached to the board. This will ensure that the circuit is able to provide the desired level of illumination.

Tips for Working with LED PCB Assembly

When working with LED PCB Assembly, there are a few tips that can help ensure a successful project. First, make sure that you have the right tools and materials for the job. This will ensure that the project is completed successfully and efficiently. Second, take the time to read and understand the instructions for the assembly process. This will help ensure that the project is completed correctly and on time. Lastly, make sure that you have a reliable supplier to provide the components for the project. This will ensure that the project is completed with the highest quality components.

Troubleshooting LED PCB Assembly

If you encounter any issues with your LED PCB Assembly project, there are a few steps you can take to troubleshoot the problem. First, make sure that the components are properly connected to the board. This will ensure that the circuit is able to function properly. Second, make sure that the LEDs are properly attached to the board. This will ensure that the circuit is able to provide the desired level of illumination. Lastly, make sure that the board is properly laid out. This will ensure that the project is completed correctly and on time.

Cost and Quality Comparison for LED PCB Assembly

When it comes to LED PCB Assembly, there is a wide range of options available in terms of cost and quality. It’s important to weigh both factors before making a decision. Generally speaking, the more expensive options tend to provide higher quality and more reliable results. However, there are also lower cost options that can provide good results. The key is to evaluate the cost and quality of each option and make the best decision for your project.

Conclusion

LED PCB Assembly is a great way to take your project to the next level. This technology offers a number of benefits, from improved reliability to reduced costs. In addition, the process is fast and efficient, making it perfect for projects that need to be completed quickly. With the right supplier and the right design considerations, you can create a reliable and visually appealing product. If you’re looking to take your project to the next level, LED PCB Assembly is the way to go.