Customized Layout PCB Design: Meeting Industry Needs

In the fast-paced world of electronics, the demand for customized printed circuit board (PCB) designs is on the rise. As technology advances and industries become more specialized, businesses require PCB layouts that cater to their unique requirements.

I. Understanding the Industry’s Needs for Layout PCB Design:

1.1 Advancements in Technology:

With rapid technological advancements, businesses across various industries are pushing the boundaries of innovation. Whether it’s consumer electronics, automotive, aerospace, medical devices, or renewable energy systems, each sector has specific requirements for its PCB designs. These needs range from compact form factors to high-speed signal integrity, power efficiency, and complex interconnections.

1.2 Specialized Applications:

Industries often require PCB designs tailored to their unique applications. For example, the automotive industry demands PCBs that can withstand extreme temperatures, and vibrations, and provide reliable performance in challenging environments. Similarly, medical devices require PCB layouts that adhere to strict safety and regulatory standards.

1.3 Time-to-Market:

In today’s competitive landscape, time-to-market is crucial. Industries demand fast turnarounds and quick prototyping for their customized PCB designs. Efficient design iterations, rapid manufacturing, and reliable delivery timelines are vital to meet the industry’s needs.

II. Winow New Energy: Catering to Customized Layout PCB Design Requirements

2.1 Design Expertise:

Winow New Energy boasts a team of highly skilled engineers and designers with extensive experience in PCB layout design. They understand the unique requirements of different industries and work closely with clients to develop customized solutions that meet their specific needs. Their expertise spans a wide range of applications, ensuring that they can cater to diverse industry requirements.

2.2 Cutting-Edge Technology:

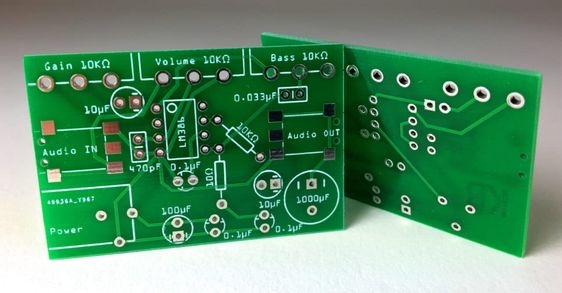

To deliver high-quality customized layout PCB designs, Winow New Energy employs state-of-the-art technology and software tools. These tools aid in optimizing the PCB layout for compact form factors, signal integrity, power efficiency, and thermal management. By leveraging the latest technology, Winow New Energy ensures that its designs meet industry standards and exceed client expectations.

2.3 Collaborative Approach:

Winow New Energy values collaboration and communication with its clients. They work closely with businesses to understand their requirements, goals, and constraints. By fostering a collaborative approach, they can offer tailored solutions that address specific challenges and deliver optimal results. This open line of communication ensures that clients’ feedback is incorporated throughout the design process, leading to greater client satisfaction.

2.4 Quick Turnaround and Prototyping:

Recognizing the importance of time-to-market, Winow New Energy has streamlined its processes to provide fast turnaround times for customized PCB designs. Their efficient design iterations and manufacturing capabilities allow them to deliver prototypes quickly, enabling clients to validate their designs and accelerate product development cycles.

2.5 Quality Assurance and Compliance:

Winow New Energy prioritizes quality assurance and compliance throughout the PCB manufacturing process. Their rigorous quality control measures ensure that the customized layout PCB designs meet industry standards and adhere to safety regulations. By maintaining strict quality control, they ensure that the final product is reliable, durable, and performs as intended.

Ⅲ. How to Do Customized Layout PCB Design with Winow New Energy?

In the world of electronics and energy solutions, customized layout PCB designs are essential for creating efficient and reliable systems. When it comes to reliable PCB manufacturing, Winow New Energy is a trusted name. With their expertise and state-of-the-art facilities, they offer a range of services to help you achieve your customized layout PCB design goals.

Step 1: Initial Consultation and Design Requirements

The first step in creating a customized layout PCB design with Winow New Energy involves an initial consultation. You will have the opportunity to discuss your project requirements, specifications, and any unique design considerations. This collaborative discussion helps Winow New Energy gain a thorough understanding of your needs and ensures that the design process aligns with your goals.

Step 2: Design and Prototyping

Once the design requirements are finalized, Winow New Energy’s skilled engineers will begin the PCB design process. They utilize industry-standard design tools and software to create a customized layout that meets your specifications. During this phase, you may be involved in design reviews and iterations to refine the design further.

After the design phase, Winow New Energy can provide prototyping services to validate the functionality and performance of the customized PCB layout. Prototyping allows you to test the design before mass production, ensuring that any necessary modifications are made early on.

Step 3: Manufacturing and Production

Once the design and prototyping stages are completed and approved, Winow New Energy initiates the manufacturing and production process. Leveraging their advanced facilities and expertise, they ensure that the PCBs are fabricated with precision and accuracy.

Throughout the manufacturing process, Winow New Energy adheres to strict quality control standards. This includes thorough inspections and testing to verify the functionality and reliability of the customized layout PCB design.

Step 4: Testing and Quality Assurance

Before delivering the finished PCBs, Winow New Energy conducts rigorous testing to ensure their performance and durability. This step involves comprehensive quality assurance procedures, including functional testing, electrical testing, and environmental testing.

Step 5: Delivery and Support

Once the testing and quality assurance processes are successfully completed, Winow New Energy packages and delivers the customized layout PCBs to your specified location. They prioritize secure packaging and safe transportation to minimize any potential damage during transit.

Additionally, Winow New Energy provides ongoing technical support and assistance to address any questions or concerns that may arise during the integration of the PCBs into your electronic systems.

Conclusion

Customized layout PCB designs play a crucial role in the success of electronic systems, and partnering with a trusted manufacturer like Winow New Energy can ensure their efficient production. By understanding the requirements and following the steps outlined in this blog, you can embark on a collaborative journey with Winow New Energy to create customized layout PCB designs that meet your specific needs. With its advanced facilities, experienced engineering team, and commitment to quality, Winow New Energy is well-equipped to deliver reliable and high-performance PCB solutions.