How to Start PCB Assembly Business

Starting a PCB assembly business can be a complex process, but it can also be a rewarding and lucrative venture if done correctly. Here are some steps you can take to get started:

- Research the market: Determine the demand for PCB assembly services in your area and identify any potential competitors.

- Develop a business plan: Outline your vision for the business, including your target market, the services you will offer, and your marketing and sales strategies.

- Obtain funding: Determine how much capital you will need to start the business and explore options for obtaining funding, such as loans, grants, or investor funding.

- Assemble your team: Consider hiring experienced PCB assembly professionals to help you get your business off the ground.

- Acquire equipment and materials: Purchase the necessary equipment and materials, including PCB manufacturing equipment, soldering tools, and electronic components.

- Establish relationships with suppliers: Build relationships with suppliers of electronic components and other materials you will need to complete PCB assembly projects.

- Market your business: Develop a marketing plan to attract potential customers and build your business’s reputation.

Starting a PCB assembly business requires a significant investment of time and resources, but with careful planning and execution, it can be a successful and rewarding endeavor.

Are you thinking about starting a PCB assembly business? If yes, this guide will help you understand the details of how to start and run a successful PCB assembly business.

Introduction to PCB Assembly Business

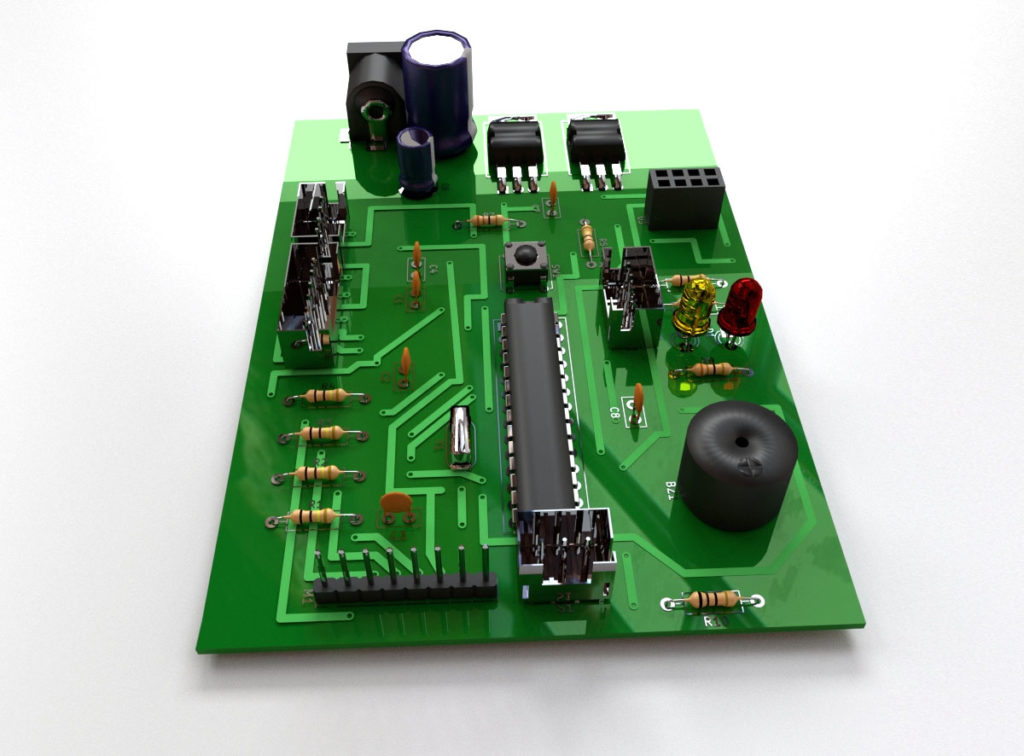

A printed circuit board (PCB) assembly business is a business that produces printed circuit boards for electronic equipment, such as computers, phones, and other electronic devices. The process of PCB assembly involves combining components, such as resistors, capacitors, integrated circuits, and other components, to create a printed circuit board that is used in many different types of electronic products.

PCB assembly businesses have become increasingly popular in recent years, as they provide a cost-effective way to create printed circuit boards for a variety of electronic products. Many businesses that produce electronic equipment rely on PCB assembly businesses to create the printed circuit boards necessary for their products.

Benefits of Starting a PCB Assembly Business

There are many benefits to starting a PCB assembly business, including:

- Low startup costs: Starting a PCB assembly business requires relatively low startup costs. You do not need to purchase expensive equipment or hire a large number of employees to get started.

- High demand: The demand for printed circuit boards is increasing, as more and more businesses rely on them to produce their products. This means that there is a large market for PCB assembly businesses.

- Flexibility: PCB assembly businesses have the flexibility to work on a variety of different types of projects, from small to large. This means that you can diversify your business and take on more projects to increase your profits.

- Profitability: PCB assembly businesses can be highly profitable, as businesses often need a large number of printed circuit boards for their products.

Necessary Skills for Starting a PCB Assembly Business

Starting a PCB assembly business requires certain skills and knowledge. You need to be familiar with the process of PCB assembly, as well as the types of components and materials used in the process. You also need to have knowledge of the different tools and equipment used in the process, such as soldering irons, solder paste, and flux.

In addition, you need to have good problem-solving skills and the ability to troubleshoot any issues that may arise during the process. It is also important to be organized and have good time management skills, as you will need to manage multiple projects at once.

Essential Equipment for a PCB Assembly Business

There is a variety of equipment that you will need to start a PCB assembly business, such as:

- Soldering irons: Soldering irons are used to connect components to the printed circuit board. It is important to choose a soldering iron that is suited to the type of components that you will be using.

- Solder paste: Solder paste is used to apply solder to the printed circuit board. You will need to choose a solder paste that is compatible with the components that you are using.

- Flux: Flux is a chemical used to remove impurities from the surface of the printed circuit board. It is important to choose the right type of flux for the components that you will be using.

- Scrub pads: Scrub pads are used to remove dirt and grease from the surface of the printed circuit board.

- Ovens: Ovens are used to bake the printed circuit board in order to set the solder.

- Magnifying lamps: Magnifying lamps are used to inspect the printed circuit board for any defects.

- Microscopes: Microscopes are used to inspect the printed circuit board in detail.

Estimating Your Costs for Starting a PCB Assembly Business

When starting a PCB assembly business, it is important to estimate your costs, so that you can budget appropriately. The costs associated with starting a PCB assembly business include the cost of purchasing the necessary equipment, such as soldering irons, solder paste, flux, scrub pads, ovens, magnifying lamps, and microscopes.

In addition, you will need to factor in the costs of supplies, such as printed circuit board materials and components, as well as the cost of renting a workspace. You should also consider the cost of hiring employees, as well as the cost of any additional services that you may need, such as legal services or accounting services.

Finding Suppliers and Clients for Your PCB Assembly Business

Once you have estimated your costs for starting a PCB assembly business, you will need to find suppliers and clients for your business. You will need to find suppliers that can provide you with the components and materials that you need for your business.

In addition, you will need to find clients that are interested in your services. You can reach out to businesses that produce electronic equipment, as they are likely to need your services. You can also advertise your services online, or attend trade shows and conferences in order to find clients.

Developing a Business Plan for Your PCB Assembly Business

Once you have found suppliers and clients for your business, you will need to develop a business plan. A business plan is a document that outlines your goals and objectives, as well as how you will achieve them. It should include information such as your business structure, the products and services that you offer, and the strategies you will use to market your business.

In addition, your business plan should include a financial plan, which outlines your expenses and income. This will help you determine whether or not your business is feasible, as well as how much capital you will need to invest in it.

Marketing Strategies for Your PCB Assembly Business

Once you have developed a business plan, you will need to develop a marketing strategy. Your marketing strategy should include tactics such as creating a website, using social media, attending trade shows and conferences, and advertising in trade magazines.

You should also consider using email marketing and search engine optimization (SEO) to reach potential customers. SEO involves optimizing your website and content for search engines, so that it appears higher in search engine results.

Tips for Successfully Running a PCB Assembly Business

Once you have developed a business plan and marketing strategy for your PCB assembly business, it is important to follow a few tips to ensure its success. These tips include:

- Quality control: Quality control is essential for running a successful PCB assembly business. You should ensure that all of your products meet the highest standards of quality.

- Streamline processes: You should streamline your processes as much as possible, so that you can work efficiently and effectively.

- Stay organized: Staying organized is key to running a successful PCB assembly business. You should keep track of all of your projects and stay on top of deadlines.

- Stay up to date: You should stay up to date with the latest trends in the industry, so that you can stay ahead of the competition.

- Invest in training: Investing in training can help you and your employees learn the latest techniques and technologies, so that you can provide the best services to your clients.

Conclusion

Starting a PCB assembly business can be a rewarding and profitable venture. It requires certain skills and knowledge, as well as the right equipment and materials. You will also need to develop a business plan and marketing strategy, and follow a few tips for success. With the right approach, you can create and run a successful PCB assembly business.