5 Steps to Finding Your Multilayer Printed Circuit Board

Step 1: Know The Basics Of The Multilayer Printed Circuit Boards

The materials and processes used in PCB manufacturing have changed over time, but the basic principles remain the same.

How do I find my multilayer PCB? The first step to understanding multilayer PCBs is to understand how they differ from single-layer boards. Single-layer boards are made up of a single copper layer that is etched onto a substrate (a sheet of plastic) with copper tracks that form the electrical connections between components on the board.

The tracks on a single-layer board can be arranged in any pattern, but the most common arrangement is called a single-sided through hole (SSTH). SSTH traces run parallel to one edge of the board only and are connected by vias (holes) drilled through the substrate and into layers below.

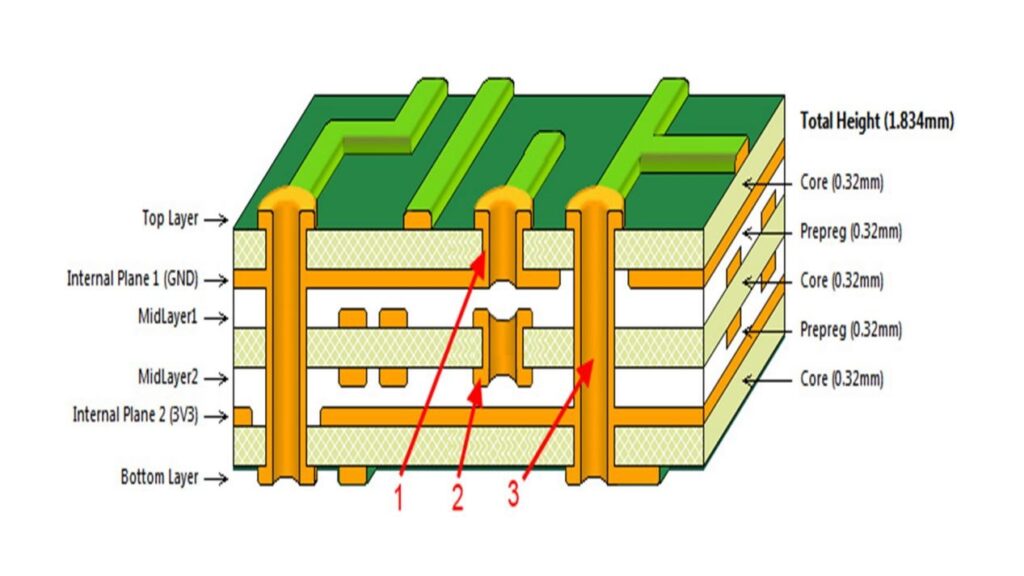

A multilayer PCB is made up of several layers of copper, each separated by a thin insulating layer such as FR4 glass fabric or FR4 epoxy glass. These layers are stacked together and etched to create conductive pathways between the layers. This allows for complex circuits to be created, often with many signal layers on top of one another.

Multilayer printed circuit boards are used in various industries such as automotive, aerospace, medical, power supply, and many more. How do I find my multilayer PCB? These boards are basically used for the manufacturing of electronic circuits, which are thin and flat. The basic purpose of these boards is to connect different components together by using wires.

Step 2: Determine the Purpose of Your Printed Circuit Board

There are several different types of printed circuit boards, including single-sided and double-sided boards, as well as single-layer and multi-layer boards. Each type has its own set of design requirements, so it’s important to know what kind of board you need before you start designing one.

How do I find my multilayer PCB? The next step is to determine the purpose of your printed circuit board. There are many different types of boards, and each has its own set of requirements. Common types include:

1. Single-Sided PCBs

These boards have only one layer of copper, and they are generally used for prototypes or very simple circuits. They are not durable enough for repeated use.

2. Double-Sided PCBs

These boards have two layers of copper and are typically used in small runs and prototypes. They can be used in production runs if they are well-designed, but they are more expensive than single-sided boards because they require more material and labor to manufacture.

3. Multilayer PCBs

These boards have several layers of copper and are often used in high-quality products such as medical devices and computing equipment. They are also known as multi-layer printed circuit boards (MLPCB) or multilayer ceramic capacitors (MLCC).

4. Surface Mount Technology (SMD)

SMD PCBs use surface mount components instead of through-hole ones because it’s faster to assemble them that way, but there’s no reason why you can’t use through-hole components instead if you want to.

5. Through-Hole Components

These are the type of components that you’re used to seeing in electronic devices. They have leads coming out of the sides that allow you to solder them into place on a PCB.

Step 3: Find A Reliable Multilayer PCB Manufacturer

The third step is to find a reliable multilayer PCB manufacturer. You can find many manufacturers online and choose one based on their reviews. Make sure that the manufacturer has good customer service and is able to meet your deadline.

Once you’ve found a reliable manufacturer, the next step is getting your printed circuit board manufactured. Before sending your design files to the manufacturer, make sure you double-check them for any errors or mistakes. Also, make sure that all of your components are placed in the right position on the board so they can be easily soldered by the manufacturer during production.

After receiving your printed circuit boards from the factory, it’s always best to inspect them before installing any components into them. This will ensure that there aren’t any manufacturing defects on them and they’re ready for use immediately after installation.

Step 4: Look At The PCB Supplier’s Current Customers and Projects

One of the best ways to ensure that you get a high-quality product is to look at the past projects of your potential PCB supplier. This will allow you to see how they perform in different situations and whether or not they are able to meet deadlines. You should also consider asking for references from their current customers as this can give you an idea of what kind of service the company provides.

Here are some questions you might want to ask:

- How many customers do you have? This will give you an idea of how big they are.

- What industries do your customers work in? If they only work in one industry, then their experience may not be very broad.

- What projects have you done for your customers? If a supplier has only done one project for one customer, then it could indicate that they don’t have much experience with other industries or products.

- What materials have you used in the past? This will give you an idea of the range of materials they can work with, which affects the cost and complexity of manufacturing your board.

Step 5: Get Customized Multilayer PCB Solutions From WINOW

If your project requires advanced circuit board technology, you will want to consider a multilayer circuit board. Here you can find WINOW to help you. As a multilayer PCB manufacturer, WINOW offers a wide range of PCB manufacturing services to meet your needs. With many years of experience, our extensive product portfolio, and state-of-the-art facilities, we have established ourselves as the preferred PCB supplier for many companies around the world.

WINOW offers high-quality, customized multilayer PCB solutions to customers around the world. We offer quick turnaround times and competitive pricing. Our team of experienced engineers will work with you to ensure your project is completed on time and at a reasonable cost.