ESD PCB Assembly – A Comprehensive Guide

Electrostatic Discharge (ESD) PCB Assembly is an important part of the development process of any product that uses printed circuit boards. It affects the overall quality, reliability, and performance of a product and it is essential that the right ESD PCB Assembly techniques and processes are used. In this article, we will take a look at what ESD PCB Assembly is, its benefits, the assembly process, common defects, troubleshooting tips, quality control, types of solutions, training courses, and services.

What is ESD PCB Assembly?

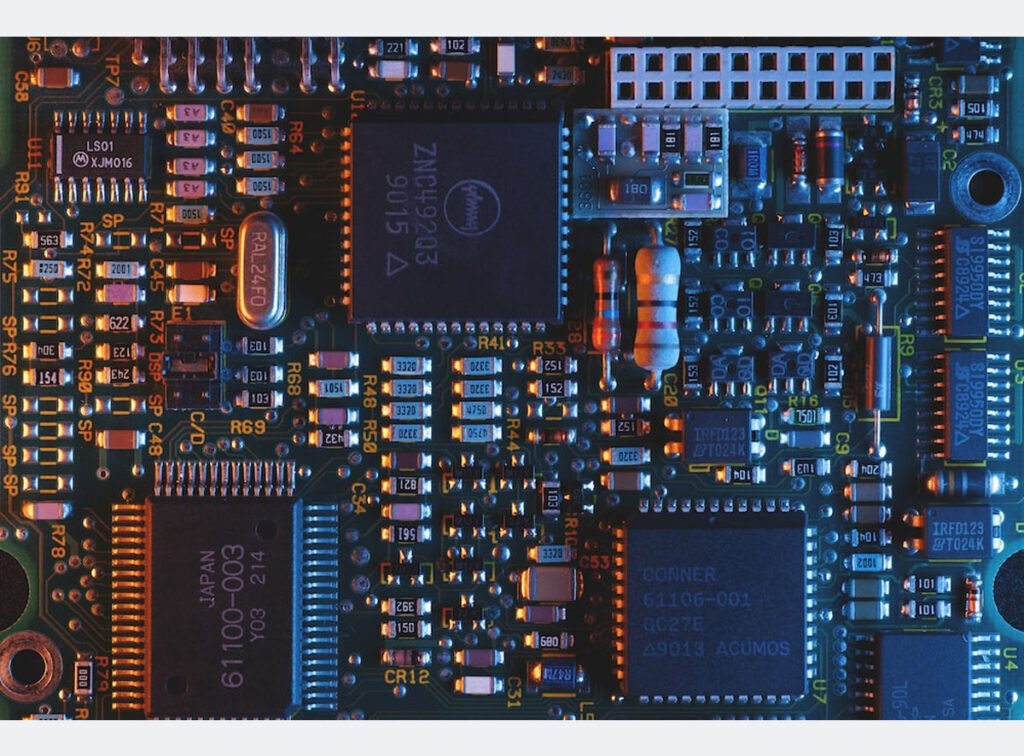

ESD PCB Assembly is the process of assembling a printed circuit board (PCB) with electrostatic discharge (ESD) protection. It involves the use of high-quality components, such as capacitors, resistors, and integrated circuits, to reduce the risk of electrostatic discharge (ESD) damage to the board and its components. The process also includes the use of specialized soldering techniques, such as wave soldering, to ensure a reliable connection between components.

The purpose of ESD PCB Assembly is to reduce the risk of ESD damage to the board and its components. ESD damage is caused by the buildup of static electricity on the board and its components, which can cause components to fail or become damaged. ESD PCB Assembly techniques and processes help to reduce the risk of ESD damage and ensure the reliability and performance of the board and its components.

Benefits of ESD PCB Assembly

ESD PCB Assembly offers a number of benefits, including increased reliability and performance, reduced risk of ESD damage, improved cost efficiency, and improved quality assurance. By using ESD PCB Assembly techniques and processes, you can ensure that your products are reliable and perform as expected.

The use of high-quality components in the assembly process helps to reduce the risk of ESD damage and improve the performance and reliability of the board and its components. The use of specialized soldering techniques, such as wave soldering, helps to ensure a reliable connection between components and reduce the risk of ESD damage.

The use of ESD PCB Assembly techniques and processes also helps to improve cost efficiency. By using high-quality components and specialized soldering techniques, you can reduce the cost of assembly, as well as reduce the cost of repairs and replacements due to ESD damage.

Finally, the use of ESD PCB Assembly techniques and processes helps to improve the quality assurance of your products. By using high-quality components and specialized soldering techniques, you can ensure that your products are reliable and perform as expected.

ESD PCB Assembly Process

The ESD PCB Assembly process involves a number of steps, including component selection and placement, soldering, testing, and inspection. The process begins with the selection and placement of components on the board. Components must be selected carefully to ensure that they are compatible with the board and its components.

Once the components have been selected and placed, the soldering process begins. This involves the use of specialized soldering techniques, such as wave soldering, to ensure a reliable connection between components. The soldering process must be done carefully to ensure that components are not damaged during the process.

Once the soldering process is complete, the board is tested to ensure that it is functioning properly. This involves the use of specialized test equipment and techniques to ensure that the board is functioning as expected. Once the board has been tested, it is inspected to ensure that it meets the required specifications.

Common ESD PCB Assembly Defects

One of the most common defects in ESD PCB Assembly is ESD damage. ESD damage can occur if components are not properly protected during assembly. This can cause components to fail or become damaged, resulting in poor performance or reliability. Other common defects include incorrect component placement, faulty soldering, and incorrect testing procedures.

To reduce the risk of ESD damage and other defects, it is important to use high-quality components and specialized soldering techniques. It is also important to use specialized test equipment and techniques to ensure that the board is functioning properly.

Tips for Troubleshooting ESD PCB Assembly

When troubleshooting ESD PCB Assembly, it is important to identify the source of the problem and take corrective action. If the problem is related to ESD damage, it is important to identify the source of the ESD and take corrective action to reduce the risk of ESD damage. This may include using high-quality components and specialized soldering techniques.

If the problem is related to incorrect component placement or faulty soldering, it is important to inspect the board to identify the source of the problem. Once the problem has been identified, corrective action can be taken to ensure that the board is functioning properly.

If the problem is related to incorrect testing procedures, it is important to use specialized test equipment and techniques to ensure that the board is functioning properly. Once the board has been tested, it is important to inspect it to ensure that it meets the required specifications.

Quality Control in ESD PCB Assembly

Quality control is an important part of ESD PCB Assembly. Quality control measures must be taken throughout the assembly process to ensure that the board meets the required specifications. This may include using high-quality components, specialized soldering techniques, and specialized test equipment and techniques.

It is also important to inspect the board after the assembly process is complete to ensure that it meets the required specifications. This may involve using specialized test equipment and techniques to ensure that the board is functioning properly. If any defects are found, it is important to take corrective action to ensure that the board meets the required specifications.

Types of ESD PCB Assembly Solutions

There are a number of different types of ESD PCB Assembly solutions available, including traditional assembly, automated assembly, and hybrid assembly. Traditional assembly involves the use of manual assembly techniques, such as hand soldering. Automated assembly involves the use of automated equipment, such as robotic soldering machines, to assemble the board. Hybrid assembly involves a combination of manual and automated assembly techniques.

Each type of assembly solution has its own advantages and disadvantages. Traditional assembly is the most cost-effective solution, but it is also the slowest. Automated assembly is the fastest solution, but it is also the most expensive. Hybrid assembly offers the best of both worlds, but it is also the most complex.

Courses for ESD PCB Assembly Training

There are a number of courses available to help you learn the basics of ESD PCB Assembly. These courses can help you understand the different components, soldering techniques, and testing procedures involved in the assembly process. The courses can also help you learn how to identify and troubleshoot common defects in the assembly process.

By taking courses in ESD PCB Assembly, you can gain a better understanding of the assembly process and ensure that your products are reliable and perform as expected. This can help to improve the quality and reliability of your products and ensure that they meet the required specifications.

ESD PCB Assembly Services

There are a number of companies that offer ESD PCB Assembly services. These companies can provide a variety of services, including component selection and placement, soldering, testing, and inspection. The services offered by these companies can help to ensure that your products are reliable and perform as expected.

By using ESD PCB Assembly services, you can reduce the risk of ESD damage and improve the performance and reliability of your products. These services can also help to improve cost efficiency and ensure that your products meet the required specifications.

Conclusion

ESD PCB Assembly is an important part of the development process of any product that uses printed circuit boards. It affects the overall quality, reliability, and performance of a product and it is essential that the right ESD PCB Assembly techniques and processes are used. In this article, we have taken a look at what ESD PCB Assembly is, its benefits, the assembly process, common defects, troubleshooting tips, quality control, types of solutions, training courses, and services.

Whether you are just starting out with ESD PCB Assembly or are looking for ways to improve the quality and reliability of your products, it is important to understand the different components, soldering techniques, and testing procedures involved in the assembly process. By taking courses in ESD PCB Assembly and using ESD PCB Assembly services, you can ensure that your products are reliable and perform as expected.