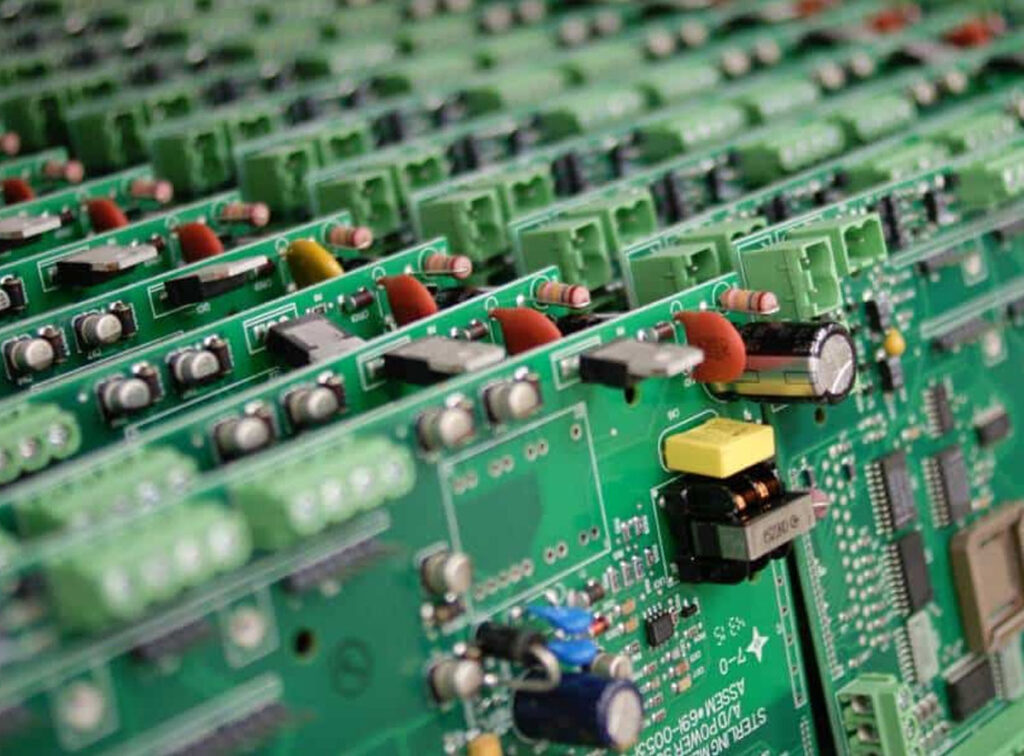

Electronic Manufacturing Services Design Development PCB Assembly in Texas

When it comes to designing and assembling printed circuit boards (PCBs), it’s important to have the right partners on your side. Working with an Electronic Manufacturing Services (EMS) provider in Texas can help you ensure that your product is designed and manufactured to the highest standards.

In this blog post, we’ll explore the benefits of working with an EMS provider in Texas, as well as the design development and PCB assembly services they offer. We’ll also discuss common mistakes to avoid when designing a PCB, what to look for in an EMS provider, and tips for working with an EMS provider in Texas.

What are Electronic Manufacturing Services?

Electronic Manufacturing Services (EMS) are services provided by companies that specialize in the design, assembly, and manufacturing of electronic components and products. These companies work with customers to provide end-to-end solutions from concept to production.

The services offered by an EMS provider can vary depending on the product and customer requirements. In general, these services include design and development, prototyping, PCB assembly, test and verification, and product manufacturing. By leveraging the expertise of an EMS provider, customers can reduce the time, cost, and risk of developing and producing PCBs.

Benefits of Electronic Manufacturing Services

Working with an EMS provider in Texas can provide a number of benefits. Some of the most important advantages of working with an EMS provider include:

- Reduced time-to-market: An EMS provider can help reduce the time it takes to design and manufacture a product. By leveraging their expertise and resources, they can help ensure that your product is designed and manufactured quickly and efficiently.

- Lower costs: An EMS provider can also help reduce production costs by leveraging their resources and experience. They can help you select the right components and materials for your project, as well as optimize the design for cost-effectiveness.

- Reduced risk: By working with an experienced EMS provider, you can reduce the risks associated with designing and manufacturing a product. An experienced provider can help you avoid common mistakes and ensure that your product meets the highest standards.

Design Development Services

When designing a PCB, it’s important to have the right design development services in place. An EMS provider can help you create a design that meets your requirements and is optimized for cost-effectiveness.

Design development services typically include schematic capture, PCB layout, and signal integrity analysis. The schematic capture process involves creating a circuit drawing that accurately represents the product. PCB layout involves creating a physical representation of the design that meets the customer’s requirements. Signal integrity analysis is used to verify the signal integrity of the design and ensure that it meets specification.

PCB Assembly in Texas

Once the design development is complete, the next step is PCB assembly. An EMS provider in Texas can provide a range of PCB assembly services, including surface mount technology (SMT) assembly, through-hole assembly, and hand soldering.

SMT assembly is the most common type of PCB assembly. This process involves mounting components onto a printed circuit board using a reflow oven and automated pick-and-place machines. Through-hole assembly is the process of manually soldering components to a PCB. Hand soldering is used for small components and is more time-consuming than SMT assembly.

Common Mistakes to Avoid when Designing a PCB

Designing a PCB can be a complex process, and there are a number of common mistakes to avoid. Some of the most important mistakes to avoid include:

- Relying on a generic design: It’s important to create a custom design that meets your product requirements. A generic design may not be optimized for your product, which can lead to problems down the line.

- Ignoring signal integrity: Signal integrity is an important factor when designing a PCB. It’s important to ensure that the design meets the required signal integrity standards.

- Choosing the wrong components: Choosing the wrong components can lead to problems with the design and performance of the product. It’s important to select components that are compatible with the design and meet the required specifications.

- Not testing the design: Testing is an important step in the design process. It’s important to test the design to ensure that it meets the required specifications and performs as expected.

Guidelines for Choosing the Right EMS Provider

When choosing an EMS provider, it’s important to consider a number of factors. Here are some guidelines to help you choose the right EMS provider for your project:

- Experience and expertise: It’s important to choose an EMS provider with the experience and expertise to meet your needs. Look for a provider with a proven track record in designing and manufacturing PCBs.

- Cost-effectiveness: An experienced EMS provider can help you reduce costs by optimizing the design for cost-effectiveness. Look for a provider that can offer competitive pricing and flexible payment options.

- Quality assurance: Quality assurance is an important factor when choosing an EMS provider. Look for a provider that offers quality assurance testing and has a track record of manufacturing high-quality products.

Advantages of Working with an Experienced EMS Provider

Working with an experienced EMS provider can provide a number of advantages. An experienced provider can help you avoid common mistakes and ensure that your product meets the highest standards. They can also help you optimize the design for cost-effectiveness and reduce the risk of errors and delays.

An experienced provider also has the resources and expertise to help you bring your product to market quickly. They can help you select the right components and materials, as well as provide design and development services.

Tips for Working with an EMS Provider in Texas

When working with an EMS provider in Texas, there are a few tips to keep in mind. Here are some tips to help you get the most out of your working relationship with an EMS provider:

- Establish clear communication: Establishing clear communication is essential when working with an EMS provider. Make sure to keep the lines of communication open and discuss any changes or issues as soon as they arise.

- Be prepared: It’s important to be prepared when working with an EMS provider. Make sure to have all the necessary information, such as design files and specs, ready before you start the process.

- Set realistic expectations: Setting realistic expectations is key when working with an EMS provider. Make sure to discuss deadlines and budgets upfront and be realistic about what can be achieved in the given timeframe.

Key Considerations for Choosing the Right EMS Provider

When choosing an EMS provider, there are a few key considerations to keep in mind. Here are some of the most important factors to consider when selecting an EMS provider:

- Experience and expertise: It’s important to choose an EMS provider with the experience and expertise to meet your needs. Look for a provider with a proven track record in designing and manufacturing PCBs.

- Cost-effectiveness: An experienced EMS provider can help you reduce costs by optimizing the design for cost-effectiveness. Look for a provider that can offer competitive pricing and flexible payment options.

- Quality assurance: Quality assurance is an important factor when choosing an EMS provider. Look for a provider that offers quality assurance testing and has a track record of manufacturing high-quality products.

Conclusion

When it comes to designing and assembling printed circuit boards (PCBs), working with an Electronic Manufacturing Services (EMS) provider in Texas can help you ensure that your product is designed and manufactured to the highest standards. An experienced EMS provider can provide design development services, PCB assembly services, and help you reduce costs and time-to-market. When choosing an EMS provider, it’s important to consider their experience and expertise, cost-effectiveness, and quality assurance.

Working with an experienced EMS provider in Texas can provide a number of benefits, from reduced time-to-market and lower costs to reduced risk and higher quality products. By leveraging the expertise of an experienced provider, you can ensure that your product meets the highest standards and is designed and manufactured quickly and efficiently.

Are you looking for an experienced EMS provider in Texas? At ABC Electronics, we specialize in design development and PCB assembly services. Contact us today to learn more about how we can help you with your project.