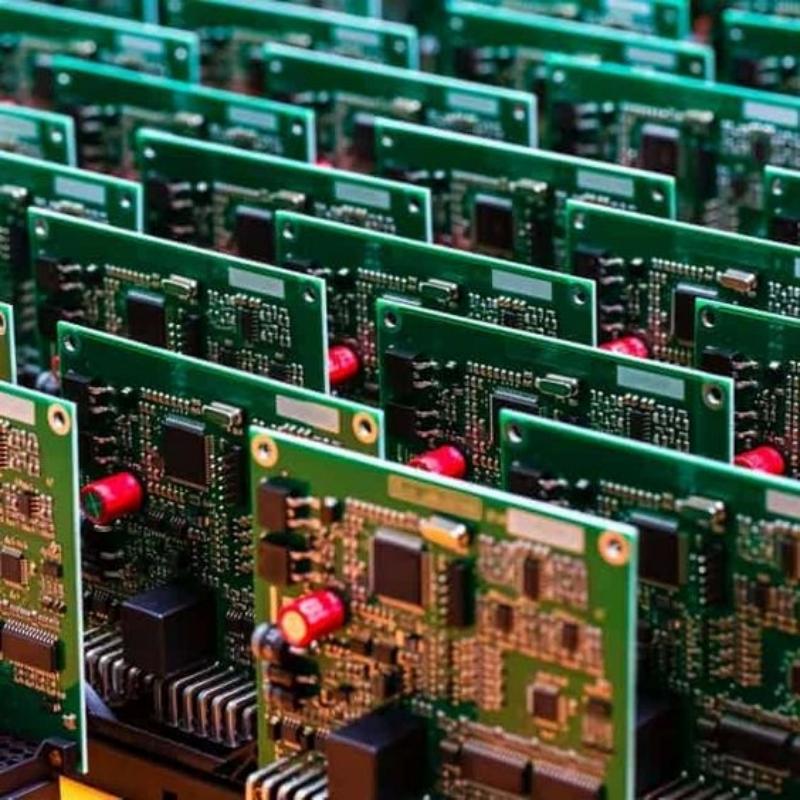

Customized PCB Assembly: Powering Innovation for Industries

Customized Printed Circuit Board (PCB) assembly plays a crucial role in bringing innovation to life. These tiny marvels, often overlooked by the average consumer, serve as the backbone of countless electronic devices we use every day. However, not all PCB assemblies are created equal. In this blog post, we explore customized PCB assembly and its applications in various industries with a spotlight on Winow, a manufacturer of customized PCB assembly.

What’s Customized PCB Assembly?

Customized PCB assembly, also known as custom PCB manufacturing, is the process of designing and fabricating printed circuit boards to meet specific requirements, rather than using off-the-shelf solutions. This approach allows for a high degree of customization, making it suitable for a wide array of applications where standard PCBs fall short.

Benefits of Customized PCB Assembly

Customized PCB assembly offers several advantages:

1. Tailored to Exact Needs: Unlike generic PCBs, customized assembly allows engineers to design boards that precisely meet the requirements of a particular application. This leads to improved performance and efficiency.

2. Space Optimization: Custom PCBs can be designed to fit into specific spaces within a device or system, making them ideal for compact electronics where space is at a premium.

3. Enhanced Functionality: Engineers can incorporate features like extra sensors, connectors, or communication protocols, enhancing the functionality of the end product.

4. Cost-Efficiency: While initial setup costs may be higher, customized PCBs can ultimately save money by reducing material waste and improving overall product performance.

5. Quality Control: Manufacturers can exercise greater control over the quality of custom PCBs, leading to more reliable and robust end products.

Diving into Customized PCB Assembly

PCBs are the heart and soul of electronic devices, providing a platform for components to communicate and function seamlessly. While standardized PCBs serve a wide range of purposes, it takes things a step further by tailoring designs to meet the unique needs of specific industries and applications.

Customized PCB Assembly: Industry-Specific Applications

1. Automotive Industry

The automotive industry relies heavily on customized PCB assembly to ensure the safety, performance, and connectivity of modern vehicles. Winow, a leading manufacturer in the field, has been at the forefront of designing and producing PCBs for automotive applications. These customized solutions include PCBs for advanced driver-assistance systems (ADAS), engine control units (ECUs), and infotainment systems. With stringent quality control measures, Winow’s PCBs contribute to the reliability and precision that drivers and manufacturers demand.

2. Medical Devices

In the realm of healthcare, precision and reliability are paramount. Customized PCB assembly plays a vital role in the development of medical devices, such as patient monitors, diagnostic equipment, and implantable devices. Winow’s expertise in medical PCBs ensures that these devices function accurately and safely, often under challenging conditions. This technology is a lifeline for healthcare professionals and patients alike, showcasing the importance of customized PCBs in saving lives.

3. Consumer Electronics

The fast-paced consumer electronics industry relies on PCBs that are not only functional but also compact and aesthetically pleasing. Winow’s customized PCB assembly services cater to these demands, allowing for the creation of smaller and more efficient electronic gadgets. From smartphones and tablets to wearable devices, these customized PCBs power the devices that have become integral to our daily lives.

Customized PCB Assembly Designing for Success: Layout Considerations

A well-thought-out PCB layout can significantly impact the overall performance and reliability of an electronic device. Here are some design tips and guidelines to keep in mind:

1. Component Placement: Proper component placement is the cornerstone of an efficient PCB design. Winow emphasizes that arranging components logically can minimize signal interference and reduce the risk of electrical noise. Carefully consider the size, orientation, and thermal requirements of each component.

2. Layer Stackup: Selecting the right layer stackup is vital. Different industries might have varying requirements for signal integrity, power distribution, and thermal management. Work closely with Winow to determine the optimal layer configuration for your custom PCB assembly.

3. Signal Routing: Pay close attention to signal traces. Ensuring signal integrity and minimizing cross-talk between traces is crucial. High-speed applications may require controlled impedance traces, which Winow specializes in implementing accurately.

4. Ergonomics: Consider the physical constraints of the device and its intended environment. The PCB should fit seamlessly into the product enclosure, allowing for easy assembly and maintenance.

Customized PCB Assembly Component Selection: Quality Matters

The components you choose for your PCB assembly can significantly impact the reliability and performance of your product. Winow’s expertise in component selection can be a game-changer. Here are some considerations:

1. Quality Assurance: Winow prioritizes the use of high-quality components from reputable suppliers. This reduces the risk of component failures and ensures longevity.

2. Availability: Consider component availability, especially for long-term projects. Winow can help you select components with stable supply chains to avoid production interruptions.

3. Lifecycle Management: For industries with extended product lifecycles, it’s essential to choose components with a long-term availability commitment from manufacturers.

Customized PCB Assembly Thermal Management: Keeping it Cool

Effective thermal management is vital for PCBs, particularly in industries where devices operate in extreme conditions or have high power requirements. Winow offers specialized thermal solutions. Here’s what you need to know:

1. Heat Dissipation: Winow designs PCBs with efficient heat dissipation in mind. This may involve the use of heat sinks, thermal vias, or even innovative cooling solutions, depending on your industry’s needs.

2. Material Selection: The choice of PCB material can impact thermal performance. Winow can advise on selecting materials with excellent thermal conductivity properties.

3. Testing and Simulation: Winow utilizes advanced testing and simulation tools to ensure your custom PCB assembly can handle the thermal loads it will encounter in the field.

Conclusion

Customized PCB assembly is the driving force behind innovation in various industries, from automotive and healthcare to consumer electronics. Winow, a prominent manufacturer in the field, has showcased its expertise in tailoring PCB solutions to meet the unique demands of these industries. As technology continues to evolve, the role of customized PCBs in powering innovation remains indispensable, and Winow stands as a testament to the limitless possibilities that customized PCB assembly can unlock.