Cheap PCB Assembly: How to Save Money on Your Next Project

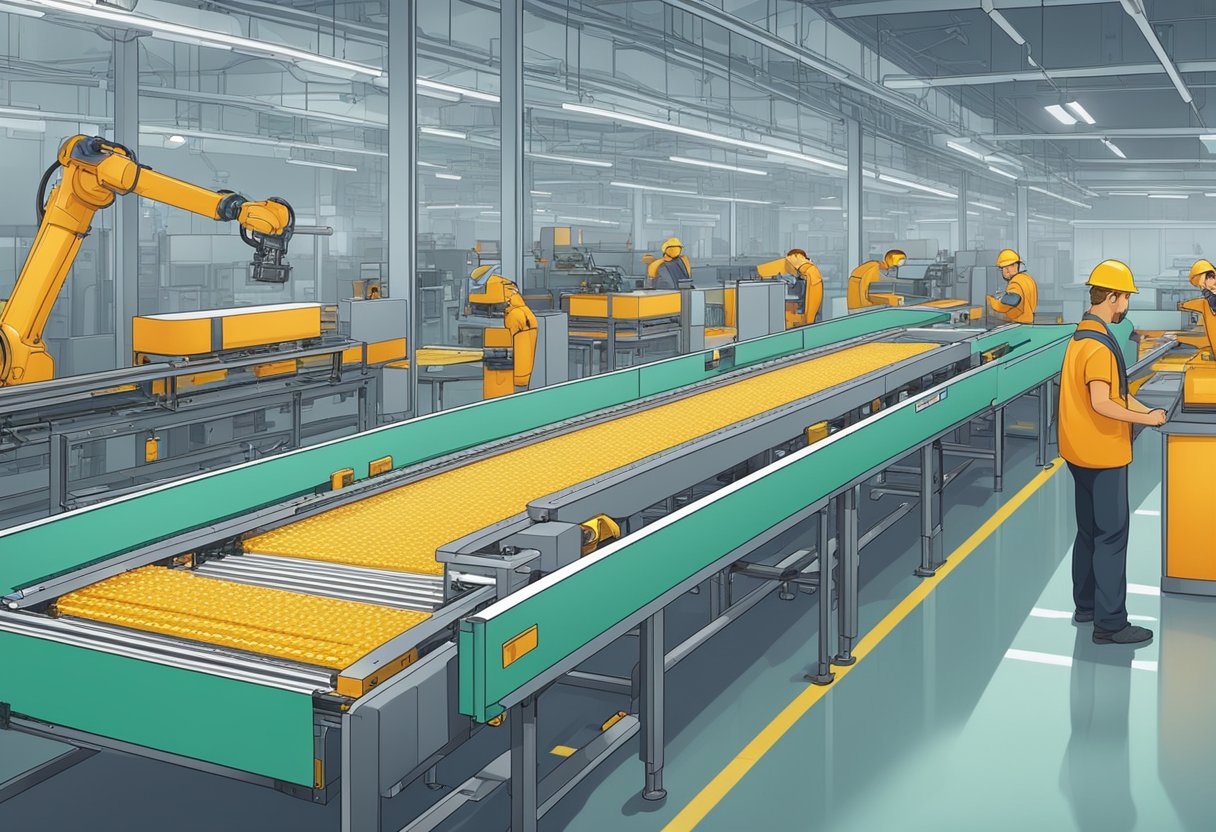

Cheap PCB assembly is a topic of great interest to many individuals and businesses who are looking to create electronic products without breaking the bank. PCB assembly refers to the process of assembling electronic components onto a printed circuit board (PCB) in order to create a functioning electronic device. With the increasing demand for electronic products, the need for affordable PCB assembly services has grown significantly.

There are various factors that contribute to the cost of PCB assembly, including the complexity of the design, the number of components required, and the size of the board. In order to reduce costs, many individuals and businesses are turning to cheap PCB assembly services that offer high-quality assembly at a lower cost. These services often utilize advanced manufacturing techniques and automation to reduce labor costs, and may also offer discounts for bulk orders.

Understanding PCB Assembly

PCB Assembly Basics

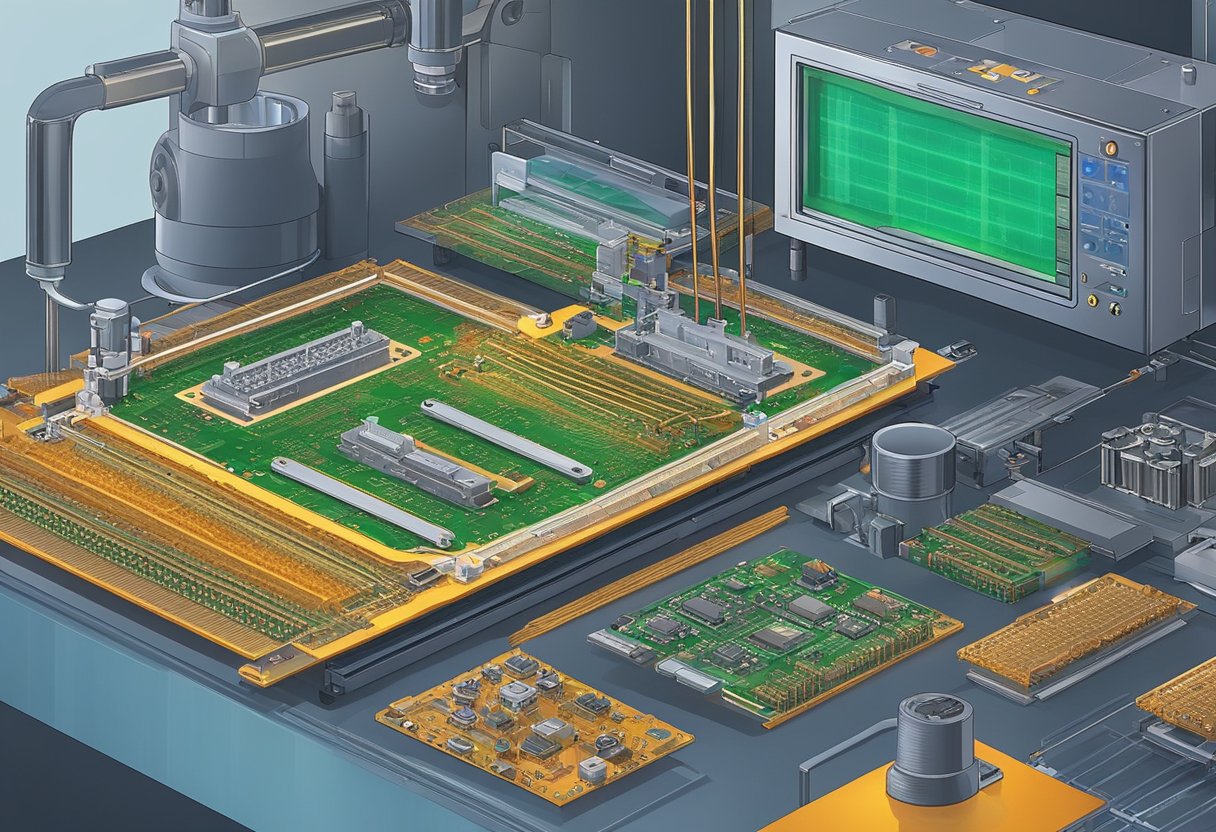

PCB (Printed Circuit Board) assembly is the process of mounting electronic components onto a PCB. The PCB serves as a platform for the components, allowing them to be connected to each other and to other electronic devices. The assembly process involves several steps, including soldering, inspection, and testing.

Soldering is the process of attaching the components to the PCB using solder. Solder is a metal alloy that melts at a low temperature and solidifies when it cools. It is used to create a permanent bond between the component and the PCB. The process of soldering can be done manually or using automated machines.

Inspection is an important step in the PCB assembly process. It involves checking the quality of the solder joints and ensuring that the components are properly placed on the PCB. Inspection can be done manually or using automated machines.

Testing is the final step in the PCB assembly process. It involves checking the functionality of the assembled PCB. Testing can be done manually or using automated machines.

Types of PCB Assembly

There are two main types of PCB assembly: Through-Hole Assembly and Surface Mount Assembly.

Through-Hole Assembly involves mounting components on the PCB by inserting leads into holes on the PCB and soldering them in place. This method is commonly used for larger components that require more mechanical support.

Surface Mount Assembly involves mounting components on the surface of the PCB using solder paste. This method is commonly used for smaller components that do not require as much mechanical support. Surface Mount Assembly is faster and more cost-effective than Through-Hole Assembly.

In conclusion, understanding the basics of PCB assembly and the types of assembly methods available can help in choosing the right method for a particular project. It is important to choose the right assembly method to ensure the quality and functionality of the final product.

Factors Affecting PCB Assembly Cost

When it comes to PCB assembly, there are several factors that can affect the overall cost of the process. These factors can vary depending on the specific project, but there are a few that tend to have the most significant impact on cost.

Components Cost

One of the most significant factors that can impact the cost of PCB assembly is the cost of the components themselves. This includes everything from the resistors and capacitors to the microprocessors and other specialized components. In general, the more complex and specialized the components are, the more expensive they will be. Additionally, the quantity of components needed for a given project can also impact cost.

PCB Complexity

The complexity of the PCB design can also impact the cost of assembly. More complex designs may require additional steps in the assembly process, which can drive up costs. This can include things like additional soldering steps, or the need for specialized equipment or techniques to complete the assembly process.

Volume and Scale

Finally, the volume and scale of the project can also impact the cost of assembly. Larger projects with higher volumes will generally have lower per-unit costs, as the fixed costs associated with setting up the assembly process can be spread out over a larger number of units. Conversely, smaller projects may have higher per-unit costs due to these fixed costs being spread out over a smaller number of units.

Overall, when it comes to PCB assembly, there are several factors that can impact the overall cost of the process. By understanding these factors and working to minimize costs where possible, it is possible to achieve high-quality PCB assemblies at an affordable price.

How to Find Cheap PCB Assembly Services

When looking for cheap PCB assembly services, there are a few key factors to consider. Here are some tips to help you find the best option for your needs.

Supplier Comparison

One of the most important steps in finding a cheap PCB assembly service is comparing different suppliers. This can help you identify the most cost-effective option without sacrificing quality. To compare suppliers, consider the following factors:

- Price: Compare the pricing of different suppliers to find the most affordable option. However, keep in mind that the lowest price may not always be the best option.

- Quality: Make sure the supplier has a good reputation for quality work. Look for reviews or ask for references from past customers.

- Lead time: Consider the lead time for each supplier to ensure they can meet your project timeline.

- Customer service: Look for a supplier with good customer service. This can ensure that any issues or concerns are addressed quickly and effectively.

Cost Reduction Strategies

In addition to comparing suppliers, there are several cost reduction strategies you can use to save money on PCB assembly. Here are a few options to consider:

- Simplify your design: A simpler PCB design can reduce the cost of assembly. Consider reducing the number of components or using standard sizes to save money.

- Use surface mount technology (SMT): SMT components are smaller and easier to assemble, which can reduce the overall cost of PCB assembly.

- Order in bulk: Ordering a larger quantity of PCBs can often result in a lower cost per unit. Consider ordering more than you need if you anticipate needing additional PCBs in the future.

By following these tips, you can find a cheap PCB assembly service that meets your needs without sacrificing quality.

Cheap PCB Assembly Techniques

When it comes to PCB assembly, there are different techniques that can be used to achieve a low-cost production. In this section, we will discuss two popular techniques: Surface Mount Technology (SMT) and Through-Hole Technology (THT).

Surface Mount Technology

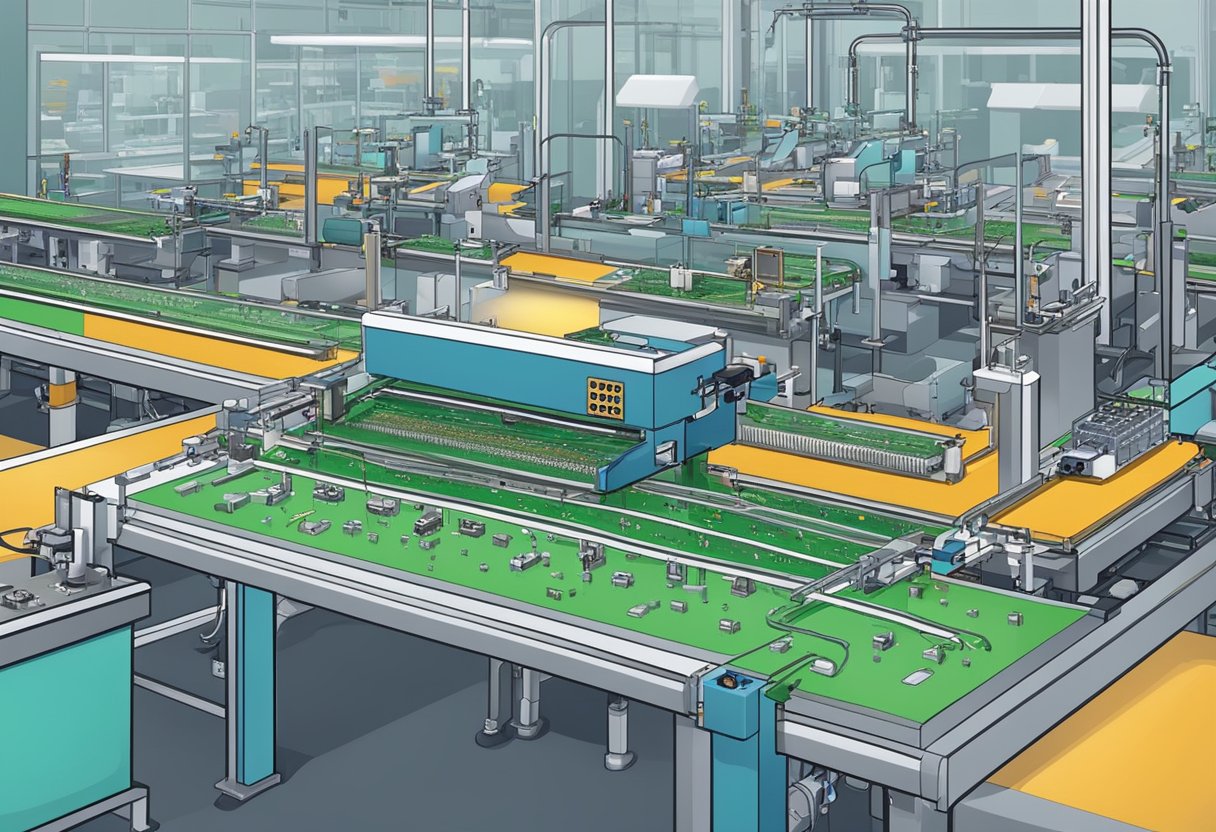

SMT is a technique that involves mounting components directly onto the surface of the PCB. This technique is widely used in modern electronics manufacturing due to its cost-effectiveness and high efficiency. SMT components are smaller and lighter, which means that they require less space on the PCB. This allows for a higher density of components, resulting in a smaller PCB size.

Some of the advantages of SMT include:

- Cost-effective: SMT components are cheaper to manufacture and assemble compared to THT components.

- High efficiency: The automated SMT assembly process is faster and more efficient, resulting in a higher production rate.

- High density: SMT components are smaller and lighter, allowing for a higher density of components on the PCB.

Through-Hole Technology

THT is a technique that involves mounting components by inserting their leads through holes drilled into the PCB. This technique is commonly used in older electronics manufacturing and is still used for some applications today. THT components are larger and heavier, which means that they require more space on the PCB.

Some of the advantages of THT include:

- Durability: THT components are more durable and can withstand higher levels of stress and vibration.

- Easy to repair: THT components are easier to replace and repair compared to SMT components.

- Better heat dissipation: THT components have larger leads that can dissipate heat more effectively.

In conclusion, both SMT and THT have their advantages and disadvantages when it comes to cheap PCB assembly. The choice of technique will depend on the specific requirements of the project.

Advantages of Low-Cost PCB Assembly

Cost Savings

One of the most significant advantages of low-cost PCB assembly is the cost savings it offers. By opting for low-cost PCB assembly, companies can save a considerable amount of money on their manufacturing costs. This is especially true for companies that need to produce a large number of PCBs. Low-cost PCB assembly services often offer volume discounts, which can help companies save even more money.

Rapid Prototyping

Another advantage of low-cost PCB assembly is rapid prototyping. With low-cost PCB assembly services, companies can quickly and easily create prototypes of their PCB designs. This allows companies to test their designs and make any necessary changes before moving on to full-scale production. Rapid prototyping also allows companies to bring their products to market faster, giving them a competitive edge.

Overall, low-cost PCB assembly offers many advantages, including cost savings and rapid prototyping. By taking advantage of these benefits, companies can improve their bottom line and bring their products to market faster.

Quality Considerations in Cheap PCB Assembly

Quality Assurance

When it comes to cheap PCB assembly, quality assurance is a critical aspect that cannot be overlooked. Although low-cost PCB assembly services tend to cut corners to reduce costs, it is still possible to achieve a high level of quality by adhering to certain standards.

One way to ensure quality assurance is by selecting a PCB assembly service that has a proven track record of delivering quality work. It is also essential to check if the service provider has any certifications, such as ISO 9001, which guarantees that the company has a quality management system in place.

Another aspect to consider is the quality of the components used in the assembly process. Cheap components may save costs, but they may also compromise the overall quality of the PCB. It is advisable to use high-quality components that are sourced from reputable manufacturers.

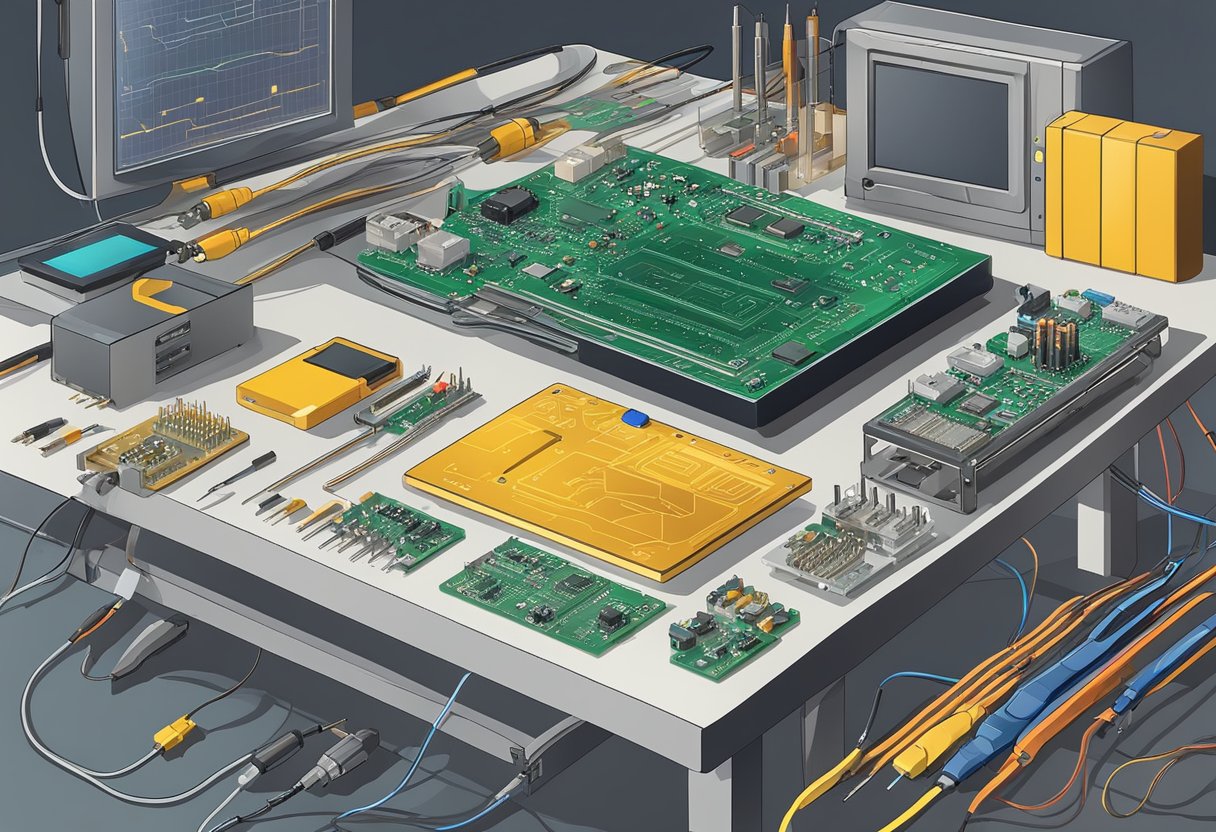

Testing Procedures

Testing is a vital part of the PCB assembly process, and it is crucial to ensure that the testing procedures are reliable and accurate. Testing procedures help to identify any defects or issues that may arise during the manufacturing process.

One way to ensure that testing procedures are reliable is by using automated testing methods. Automated testing methods are more accurate and faster than manual testing methods, and they help to reduce the risk of human error.

It is also essential to test the PCB assembly under different conditions, such as temperature and humidity, to ensure that it can withstand different environmental conditions. This helps to ensure that the PCB assembly can function correctly under different conditions and reduces the risk of failure.

In conclusion, quality considerations are critical when it comes to cheap PCB assembly. By adhering to certain standards, such as selecting a reputable service provider and using high-quality components, it is possible to achieve a high level of quality. Testing procedures are also essential to ensure that the PCB assembly is reliable and can function correctly under different conditions.

Design Tips for Affordable PCB Assembly

Design for Manufacturability

Designing for manufacturability is essential in achieving affordable PCB assembly. Here are some tips to help you design your PCB with manufacturability in mind:

- Keep it simple: Simple designs are easier and cheaper to manufacture. Avoid complex designs with too many layers, vias, and components.

- Use standard components: Using standard components reduces the cost of sourcing and assembly. Avoid using custom components unless necessary.

- Use standard board sizes: Standard board sizes are readily available and cheaper than custom sizes. Avoid designing custom board sizes unless necessary.

- Minimize board thickness: Thicker boards require more material and are more expensive to manufacture. Keep your board thickness as minimal as possible.

Material Selection

Material selection is another crucial aspect of affordable PCB assembly. Here are some tips to help you select affordable materials:

- Choose the right substrate: The substrate is the foundation of your PCB. Choose a substrate that is affordable and readily available. FR-4 is a popular and affordable substrate choice.

- Select the right copper weight: Copper weight affects the cost of your PCB. Choose a copper weight that is suitable for your application without being excessive.

- Choose affordable finishes: The finish is the final coating on your PCB. Choose a finish that is affordable and suitable for your application. HASL is a popular and affordable finish choice.

By following these design tips, you can achieve affordable PCB assembly without compromising on quality and functionality.

Outsourcing vs. In-House Assembly

When it comes to PCB assembly, companies have two options: outsourcing or in-house assembly. Each approach has its own set of advantages and disadvantages, and the decision ultimately depends on the specific needs and resources of the company.

Pros and Cons of Outsourcing

Outsourcing PCB assembly can be a cost-effective solution for companies that do not have the resources or expertise to handle the process in-house. By outsourcing, companies can benefit from the expertise of experienced professionals who have the necessary equipment and technology to produce high-quality PCBs.

However, outsourcing also has its drawbacks. Companies may have less control over the assembly process, which can lead to delays and quality issues. There is also the risk of intellectual property theft, as companies may have to share their design files with the outsourcing partner.

When to Choose In-House Assembly

In-house assembly can be a good option for companies that have the necessary resources and expertise to handle the process themselves. By keeping the assembly process in-house, companies can maintain greater control over the quality and timing of the production process.

However, in-house assembly can also be costly, as companies need to invest in the necessary equipment and technology. In addition, companies may need to hire and train staff to handle the assembly process, which can be time-consuming and expensive.

Ultimately, the decision to outsource or keep assembly in-house depends on the specific needs and resources of the company. Companies should carefully weigh the pros and cons of each approach before making a decision.

Lead Times and Delivery for Budget PCB Assembly

When it comes to budget PCB assembly, managing expectations is key. While cost is a major factor, it’s important to keep in mind that lead times and delivery options may differ from higher-priced services.

Managing Expectations

Budget PCB assembly typically has longer lead times than more expensive options. This is because the assembly process may take longer due to the use of automated equipment and less labor-intensive processes. It’s important to communicate these lead times to clients and manage their expectations accordingly.

Additionally, budget PCB assembly may have limited delivery options. Some services may only offer standard shipping, which can take longer to arrive and may not have tracking information. It’s important to make sure clients are aware of these limitations and offer alternatives if necessary.

Expedited Options

While budget PCB assembly may have longer lead times and limited delivery options, there are still expedited options available. Some services may offer expedited assembly and shipping for an additional fee. It’s important to weigh the cost of these options against the benefits and communicate them clearly to clients.

Overall, budget PCB assembly can be a cost-effective option for clients, but it’s important to manage expectations and communicate limitations clearly. By doing so, clients can make informed decisions and be satisfied with the end result.

Case Studies: Successful Cheap PCB Assembly Projects

Small Business Examples

Small businesses often have limited budgets and resources. However, with the help of cheap PCB assembly services, they can still bring their ideas to life. One such example is a small robotics company that needed to manufacture a custom PCB for their latest project. They opted for a cheap PCB assembly service and were able to get their PCBs assembled quickly and at a fraction of the cost of traditional PCB manufacturing. This allowed them to bring their product to market faster and at a more affordable price point.

Another small business that benefited from cheap PCB assembly services was a startup company that needed to manufacture a small batch of PCBs for their prototype. They were able to get their PCBs assembled quickly and at a low cost, which allowed them to test their prototype and make improvements before moving on to larger-scale production.

Large Scale Operations

Large companies also benefit from cheap PCB assembly services, especially when they need to manufacture PCBs in large quantities. One such example is a consumer electronics company that needed to manufacture a large batch of PCBs for their latest product. They opted for a cheap PCB assembly service and were able to get their PCBs assembled quickly and at a significantly lower cost than traditional PCB manufacturing. This allowed them to keep their production costs low and offer their product at a more competitive price point.

Another large company that benefited from cheap PCB assembly services was a medical device manufacturer that needed to manufacture a large quantity of PCBs for their latest product. They were able to get their PCBs assembled quickly and at a low cost, which allowed them to keep their production costs low and offer their product at an affordable price point.

In conclusion, cheap PCB assembly services are a great option for both small businesses and large companies looking to manufacture PCBs quickly and at a low cost. By opting for these services, businesses can bring their products to market faster and at a more affordable price point, which can help them gain a competitive edge in their respective industries.

Future Trends in PCB Assembly and Cost Savings

Technological Advances

The world of PCB assembly is rapidly evolving, with new technologies being developed to improve efficiency and reduce costs. One such technology is the use of automated optical inspection (AOI) systems, which can quickly and accurately detect defects in PCBs, saving time and reducing waste. Another trend is the use of 3D printing to create custom PCBs, which can be more cost-effective than traditional methods.

Market Predictions

The PCB assembly market is expected to continue growing in the coming years, driven by the increasing demand for electronic devices. This growth is expected to lead to increased competition among PCB assembly companies, which may result in lower prices for consumers. Additionally, the rise of the Internet of Things (IoT) is expected to create new opportunities for PCB assembly companies, as more and more devices become connected and require PCBs.

Overall, the future of PCB assembly looks bright, with new technologies and market trends driving innovation and cost savings. As the industry continues to evolve, consumers can expect to see more efficient and cost-effective PCB assembly solutions.