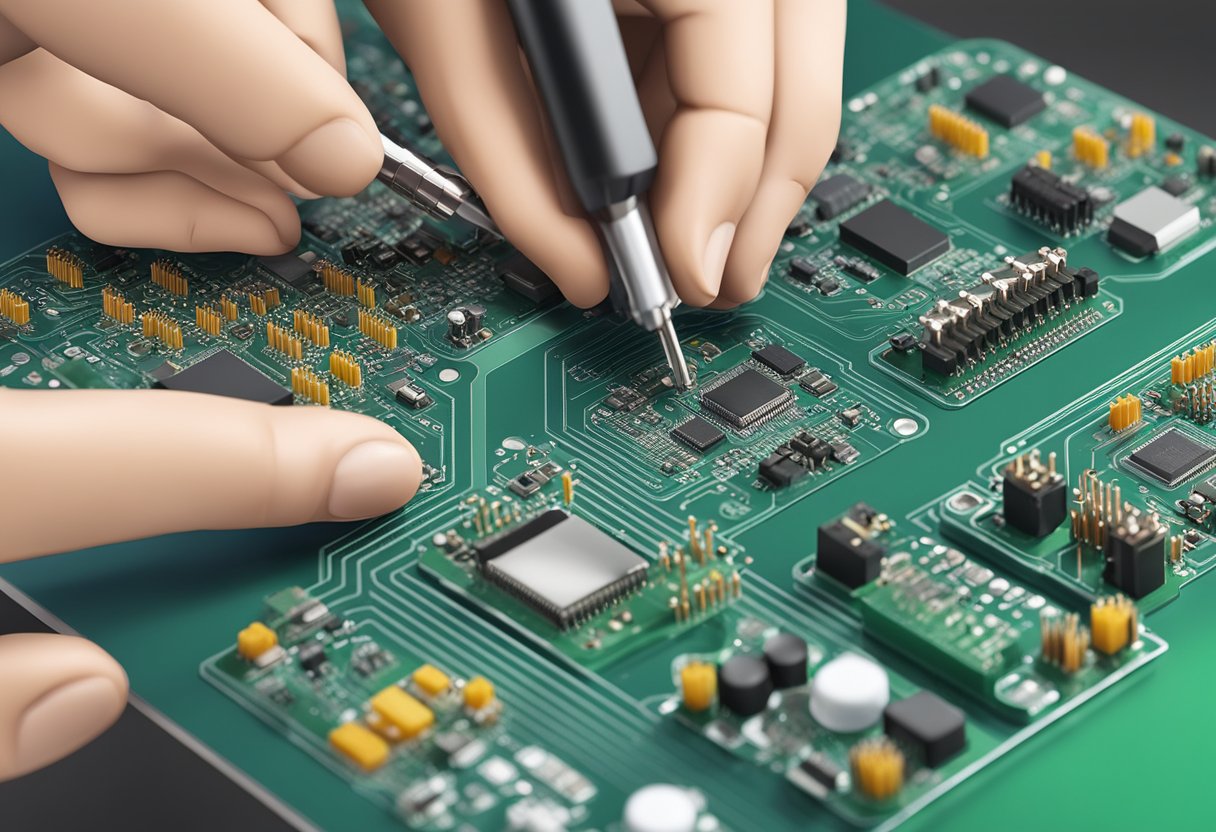

Custom PCB Board Assembly: Tips and Best Practices

Custom PCB board assembly is a process of assembling printed circuit boards (PCBs) based on specific requirements. PCBs are used in various electronic devices and have become an essential component in the manufacturing industry. Custom PCB board assembly allows for the creation of unique PCBs that meet specific needs and requirements.

The process of custom PCB board assembly involves several steps, including designing the PCB layout, selecting the components, and assembling the PCB. The design of the PCB layout is crucial as it determines the functionality and performance of the final product. Once the layout is finalized, the components are selected based on the specifications and requirements of the project. The assembly process involves placing the components onto the PCB and soldering them in place.

Custom PCB board assembly has become increasingly popular due to its ability to create unique and specialized PCBs. It allows for the creation of complex circuits and miniaturization of electronic devices. Additionally, custom PCB board assembly can reduce costs and improve the efficiency of manufacturing processes. As technology continues to advance, custom PCB assembly will play a vital role in the development and production of electronic devices.

Overview of PCB Assembly Process

Custom PCB board assembly is a complex process that involves several stages, including PCB design and layout, component sourcing, and assembly. In this section, we will provide an overview of the PCB assembly process.

PCB Design and Layout

The first step in the PCB assembly process is designing and laying out the PCB. This involves creating a schematic diagram of the circuit and converting it into a physical layout that can be manufactured. PCB design software is used to create the layout, which includes placing components and routing the traces that connect them.

Once the layout is complete, it is checked for errors and optimized for manufacturability. This includes ensuring that the design meets the manufacturer’s specifications for minimum trace widths, hole sizes, and other parameters. The final layout is then sent to the manufacturer for fabrication.

Component Sourcing

The next step in the PCB assembly process is sourcing the components. This involves identifying the components needed for the design, selecting suppliers, and ordering the parts. The components must be sourced from reputable suppliers and meet the specifications required for the design.

During the sourcing process, it is important to consider factors such as lead times, availability, and cost. Some components may be difficult to source or have long lead times, which can delay the assembly process. It is important to work with suppliers who can provide the necessary components within the required timeframe.

In conclusion, the PCB assembly process involves several stages, including PCB design and layout and component sourcing. It is important to work with experienced professionals who can guide you through the process and ensure that your custom PCB board is manufactured to the highest standards.

SMT and Through-Hole Assembly Techniques

Surface-Mount Technology (SMT)

Surface-mount technology (SMT) is a widely used assembly technique for printed circuit boards (PCBs). SMT components are mounted directly onto the surface of the PCB, as opposed to through-holes. This technique allows for smaller and more compact designs, as well as faster assembly times.

SMT components come in a variety of sizes, from large ICs to tiny resistors and capacitors. They are typically mounted using solder paste, which is applied to the PCB using a stencil. The components are then placed onto the paste and heated, causing the solder to melt and create a permanent bond.

SMT assembly requires specialized equipment, such as pick-and-place machines and reflow ovens. It also requires careful attention to detail, as small variations in component placement or soldering can cause issues with functionality.

Through-Hole Technology (THT)

Through-hole technology (THT) is an older assembly technique that involves mounting components through holes drilled into the PCB. This technique is still used in some applications, particularly for components that require a high level of mechanical stability or are too large for SMT.

THT components are typically larger than SMT components and have leads that are inserted into the holes in the PCB. The leads are then soldered to the opposite side of the PCB to create a permanent bond.

THT assembly requires less specialized equipment than SMT assembly, but it can be more time-consuming and labor-intensive. It also requires careful attention to detail, as misaligned components or poor soldering can cause issues with functionality.

In summary, both SMT and THT assembly techniques have their advantages and disadvantages. SMT is faster and more compact, but requires specialized equipment and attention to detail. THT is more stable and can be used for larger components, but is more time-consuming and labor-intensive. The choice of assembly technique depends on the specific needs of the application.

Custom PCB Assembly Equipment

Custom PCB assembly requires specialized equipment to ensure precision and accuracy. The following subsections describe the essential equipment used in custom PCB assembly.

Pick and Place Machines

Pick and place machines are used to accurately place surface mount components onto PCBs. These machines use a combination of vacuum nozzles and computer-controlled motors to pick up components from reels or trays and place them onto the PCB. Pick and place machines can place components at a rate of up to 50,000 components per hour, making them essential for high-volume production.

Reflow Soldering Ovens

Reflow soldering ovens are used to melt and reflow solder paste onto the PCB, forming a strong bond between the components and the board. These ovens use a combination of heat and time to melt the solder paste and then cool it down to create a solid joint. Reflow ovens are available in different sizes and configurations, depending on the size and complexity of the PCB being assembled.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) machines are used to inspect the PCB after assembly to ensure that all components are correctly placed and soldered. These machines use high-resolution cameras and specialized software to detect defects such as missing components, misplaced components, or solder bridges. AOI machines can inspect PCBs at a rate of up to 10,000 components per hour, making them essential for high-volume production.

Overall, custom PCB assembly requires a combination of specialized equipment and skilled technicians to ensure high-quality and reliable products.

Quality Assurance in PCB Assembly

PCB assembly is a critical process that requires strict quality control measures to ensure that the final product meets the required specifications. Quality assurance is an essential aspect of the PCB assembly process, and it involves various procedures and standards that must be adhered to for the successful production of high-quality PCBs.

Testing Procedures

Testing is a critical part of quality assurance in PCB assembly. It involves a series of tests that are conducted to ensure that the PCB meets the required specifications. The testing process includes visual inspection, electrical testing, and functional testing.

Visual inspection involves checking the PCB for any defects or abnormalities such as scratches, cracks, or missing components. Electrical testing involves checking the electrical connectivity of the PCB, and functional testing involves testing the PCB’s performance to ensure that it meets the required specifications.

Certification Standards

Certification standards are another critical aspect of quality assurance in PCB assembly. Certification standards are set by various regulatory bodies and organizations to ensure that the PCB meets the required standards. Some of the certification standards that must be adhered to during PCB assembly include IPC-A-610, IPC-J-STD-001, and ISO 9001.

IPC-A-610 is a standard that defines the acceptability criteria for electronic assemblies, while IPC-J-STD-001 is a standard that defines the requirements for soldered electrical and electronic assemblies. ISO 9001 is a standard that defines the requirements for a quality management system.

In conclusion, quality assurance is a critical aspect of PCB assembly that involves various procedures and standards that must be adhered to for the successful production of high-quality PCBs. The testing process and certification standards are essential measures that must be taken to ensure that the PCB meets the required specifications.

Turnkey Solutions for PCB Assembly

When it comes to PCB assembly, turnkey solutions provide a comprehensive service that covers everything from sourcing components to final assembly and testing. This approach can save time and money, as well as ensuring a high-quality end product.

Full Turnkey Services

Full turnkey services provide a complete solution for PCB assembly, from start to finish. This includes sourcing components, PCB fabrication, assembly, testing, and shipping. By handling all aspects of the process, full turnkey services can reduce lead times and minimize the risk of errors or delays.

In addition to saving time and effort, full turnkey services can also help to optimize costs. By consolidating the procurement process, PCB manufacturers can leverage their buying power to negotiate better prices for components. This can result in significant savings, particularly for high-volume orders.

Partial Turnkey Services

Partial turnkey services offer a more flexible approach to PCB assembly. In this model, the customer provides some or all of the components, while the PCB manufacturer handles the rest of the process. This can be useful for customers who have existing relationships with component suppliers, or who have specific requirements for certain components.

Partial turnkey services can also be a good option for customers who are working with a limited budget. By providing some of the components themselves, customers can reduce the overall cost of the project while still benefitting from the expertise and resources of the PCB manufacturer.

In conclusion, turnkey solutions for PCB assembly offer a range of benefits for customers, including reduced lead times, cost savings, and high-quality end products. Whether you opt for full or partial turnkey services, working with a reputable PCB manufacturer can help to ensure a successful outcome for your project.