PCB Assembly Made Cheap: Tips and Tricks for Affordable Manufacturing

PCB assembly is an essential process in the manufacturing of electronic products. It involves the process of assembling various electronic components onto a printed circuit board (PCB) to create a functional electronic device. PCB assembly can be a costly process, especially for small businesses or hobbyists who need to keep costs low.

Fortunately, there are ways to reduce the cost of PCB assembly. One of the most effective ways is to use cheap PCB assembly services. These services offer affordable PCB assembly solutions without compromising on quality. They use advanced manufacturing techniques and equipment to ensure that the final product meets the required specifications. By using cheap PCB assembly services, businesses and hobbyists can save money on their manufacturing costs and invest in other areas of their business.

Understanding PCB Assembly

Basics of PCB Manufacturing

PCB stands for Printed Circuit Board, which is an essential component in electronic devices. PCBs are made up of a substrate material, copper traces, and layers of insulation. The manufacturing process of PCBs involves several steps, including designing the layout, printing the design onto the substrate, and etching the copper traces.

The first step in PCB manufacturing is designing the layout. This involves creating a schematic diagram of the circuit and then translating it into a physical layout. The layout is then printed onto the substrate using a special printer that can print in high resolution.

Once the layout is printed, the next step is to etch the copper traces. This is done by exposing the substrate to a chemical solution that dissolves the copper in the areas where it is not protected by the printed layout. After etching, the remaining copper traces are left on the substrate, forming the circuit.

Components of PCB Assembly

PCB assembly involves the process of attaching electronic components to the PCB. This process includes placing the components on the board, soldering them into place, and testing the board to ensure that it is functioning correctly.

The first step in PCB assembly is to place the components on the board. This is done using a pick-and-place machine, which can quickly and accurately place components on the board.

Once the components are in place, the next step is to solder them into place. This is done using a soldering iron or a reflow oven, depending on the type of components being used.

After soldering, the board is then tested to ensure that it is functioning correctly. This involves testing the electrical connections between the components and checking for any defects in the board.

In conclusion, understanding the basics of PCB manufacturing and the components of PCB assembly is essential for anyone interested in electronics. By following these steps, one can create high-quality PCBs that are both reliable and cost-effective.

Cost Factors in PCB Assembly

When it comes to PCB assembly, cost is an important consideration. There are several factors that can affect the cost of PCB assembly, including material costs, labor expenses, volume and economies of scale, and technology and precision requirements.

Material Costs

The cost of materials is one of the most significant factors in PCB assembly. The type of materials used can have a significant impact on the overall cost of the project. Some materials, such as gold and silver, are more expensive than others, and can significantly increase the cost of the PCB assembly.

Labor Expenses

Labor expenses are another important factor in PCB assembly cost. The cost of labor can vary depending on the location of the assembly facility and the skill level of the workers. Highly skilled workers may demand higher wages, which can increase the overall cost of the project.

Volume and Economies of Scale

Volume and economies of scale can also impact the cost of PCB assembly. Generally, the larger the volume of PCBs being produced, the lower the cost per unit. This is because larger volumes allow for greater efficiencies in the manufacturing process, which can help to reduce the overall cost of the project.

Technology and Precision Requirements

Finally, technology and precision requirements can also impact the cost of PCB assembly. Advanced technologies and precision requirements can require specialized equipment and highly skilled workers, which can increase the overall cost of the project.

In conclusion, when considering the cost of PCB assembly, it is important to take into account material costs, labor expenses, volume and economies of scale, and technology and precision requirements. By carefully considering these factors, it is possible to find a cost-effective solution that meets the needs of your project.

Finding Affordable PCB Assembly Services

When it comes to PCB assembly, finding affordable services can be a challenge. However, with the right approach, it’s possible to find quality assembly services that fit within your budget. Here are some tips for finding affordable PCB assembly services.

Local vs. Overseas Manufacturers

One of the first decisions to make when looking for affordable PCB assembly services is whether to work with a local or overseas manufacturer. Local manufacturers may be more expensive, but they offer the advantage of being able to visit the facility in person and work closely with the team. On the other hand, overseas manufacturers may be cheaper, but there can be communication and quality control issues.

Online Marketplaces

Another option for finding affordable PCB assembly services is to use online marketplaces. These platforms allow you to browse through a variety of manufacturers and compare prices and services. Some popular online marketplaces for PCB assembly services include Alibaba, PCBWay, and JLCPCB.

Trade Shows and Industry Contacts

Attending trade shows and reaching out to industry contacts can also be a useful way to find affordable PCB assembly services. This approach allows you to connect with manufacturers directly and negotiate prices and services. Additionally, trade shows provide an opportunity to see the latest technology and trends in the industry.

By considering these options and doing your research, you can find affordable PCB assembly services without sacrificing quality.

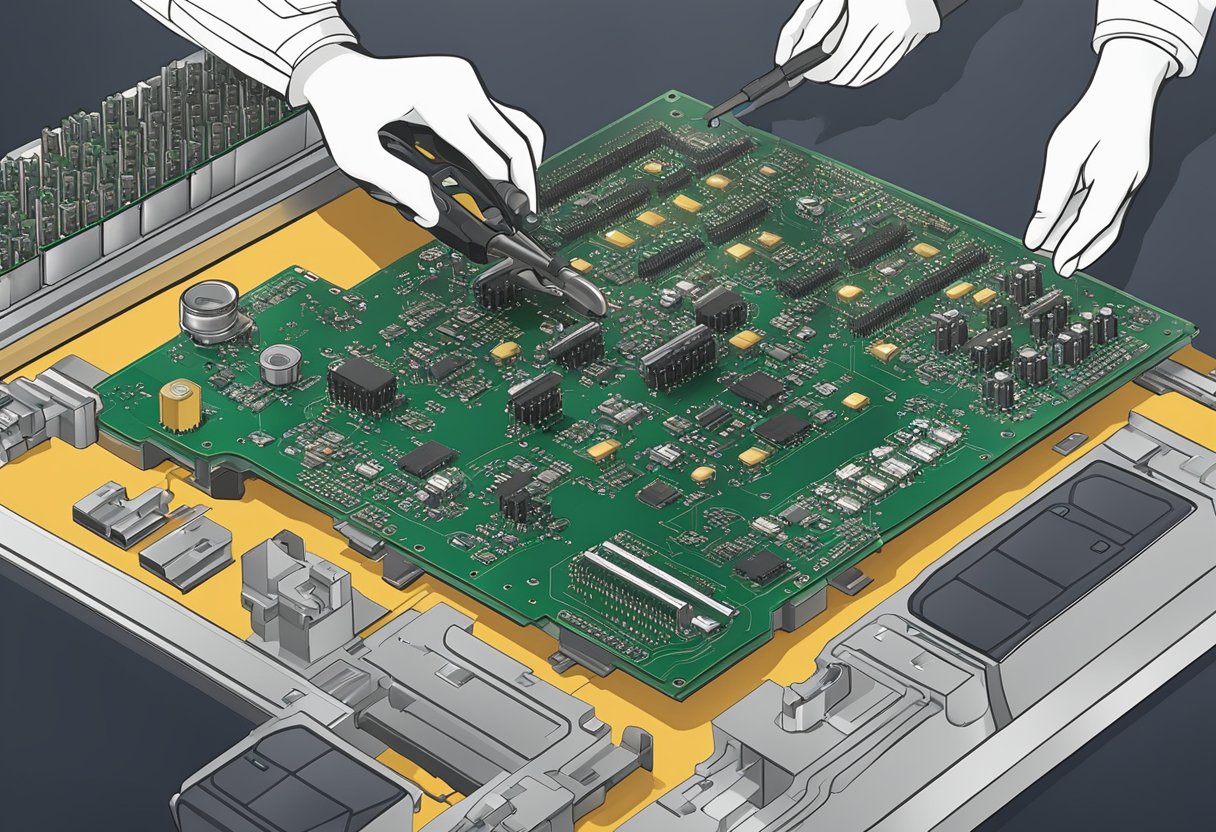

DIY PCB Assembly

Tools and Equipment Needed

To assemble a PCB at home, one needs a set of tools and equipment. Here are some of the essential items required for DIY PCB assembly:

- Soldering iron and solder wire

- PCB board

- Components such as resistors, capacitors, transistors, and diodes

- Flux

- Soldering stand

- Wire cutters

- Tweezers

- Multimeter

- PCB drill

Step-by-Step Guide

Here is a step-by-step guide to help you assemble your PCB:

- Start by placing the components on the PCB board. Ensure that the components are placed correctly as per the circuit diagram.

- Once the components are in place, start soldering them one by one. Apply a small amount of flux on the component leads and PCB pads to ensure a good solder joint.

- Use the soldering iron to heat the component lead and PCB pad simultaneously. Once the solder melts, remove the iron and let the joint cool down.

- Repeat the process for all the components until the entire circuit is assembled.

- Once the assembly is complete, use a multimeter to check for any short circuits or open circuits.

- Finally, drill holes in the PCB board to mount it on the enclosure or chassis.

By following these simple steps, one can easily assemble a PCB at home. However, it is important to note that DIY PCB assembly requires some level of expertise and caution. One should take necessary safety precautions and follow the instructions carefully to avoid any damage to the components or the PCB board.

Reducing Costs in PCB Assembly

Design for Manufacturability

Design for Manufacturability (DFM) is a critical aspect of reducing costs in PCB assembly. DFM involves designing the PCB in a way that makes it easy and cost-effective to manufacture. This includes designing the PCB with standard components, avoiding complex shapes and sizes, and minimizing the number of drill holes and vias. By designing the PCB with DFM principles in mind, the assembly process is streamlined, reducing the time and cost associated with manufacturing.

Component Sourcing Strategies

Sourcing components is another area where costs can be reduced in PCB assembly. One strategy is to source components from multiple suppliers, taking advantage of price differences between suppliers. Another strategy is to use off-the-shelf components rather than custom components, which can be more expensive. Additionally, using components that are readily available and in high demand can also reduce costs, as suppliers are more likely to offer competitive pricing.

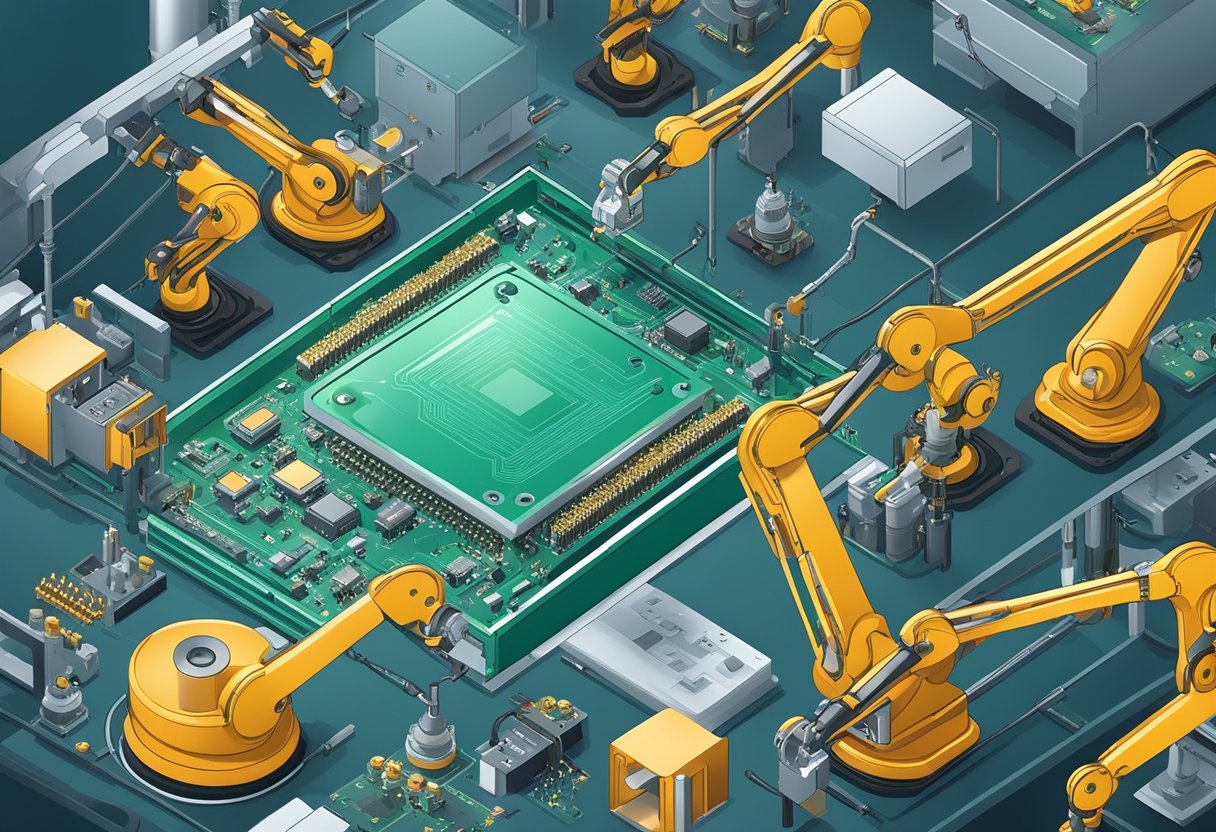

Optimizing for Production

Optimizing the PCB design for production is another way to reduce costs in PCB assembly. This includes optimizing the layout of the PCB to minimize the number of assembly steps required, using surface mount technology (SMT) components instead of through-hole components, and designing the PCB to be assembled using automated equipment. By optimizing the PCB design for production, the assembly process is faster and more efficient, resulting in lower costs.

In conclusion, reducing costs in PCB assembly requires a combination of strategies, including designing for manufacturability, sourcing components strategically, and optimizing the design for production. By implementing these strategies, PCB manufacturers can reduce costs and remain competitive in the marketplace.

Quality vs. Cost

When it comes to PCB assembly, there is often a trade-off between quality and cost. While it may be tempting to go for the cheapest option, it is important to consider the long-term impact of this decision.

Assessing Quality Standards

One way to ensure quality in PCB assembly is to look for manufacturers that adhere to industry standards. These standards set guidelines for everything from design and layout to materials and testing. Some common standards include IPC-A-610, IPC-6012, and ISO 9001.

In addition to industry standards, it is also important to consider the manufacturer’s own quality control processes. This may include things like visual inspections, automated testing, and statistical process control.

Long-Term Reliability

While cost may be a primary concern in the short term, it is important to consider the long-term reliability of the PCB assembly. Cheaper options may cut corners in areas like materials or testing, which can lead to issues down the line. This can result in costly repairs or even complete failure of the PCB.

Investing in higher quality PCB assembly may cost more upfront, but it can ultimately save time and money in the long run. By ensuring that the assembly is reliable and durable, it can help to prevent costly downtime and repairs.

In summary, when it comes to PCB assembly, it is important to carefully weigh the trade-off between quality and cost. While cheaper options may be tempting, investing in higher quality assembly can ultimately lead to greater reliability and cost savings over time.

Case Studies of Affordable PCB Assembly

Small Business Solutions

Small businesses often face the challenge of finding affordable PCB assembly services that don’t compromise on quality. One such company that offers affordable PCB assembly solutions is PCBWay. They offer a range of services including PCB fabrication, assembly, and testing. Their assembly services start from as low as $30 for 10 pieces of PCB assembly.

Another company that caters to small business needs is JLCPCB. They offer a range of PCB assembly services starting from $2 for 10 pieces of PCB assembly. They also offer a range of additional services such as PCB testing, SMT assembly, and stencil services.

Large Scale Production Examples

For large scale production, it is important to find a PCB assembly service that offers competitive pricing without compromising on quality. One such company is RayMing Technology. They offer a range of PCB assembly services including through-hole assembly, SMT assembly, and mixed assembly. They also offer a range of additional services such as PCB testing, conformal coating, and box build assembly.

Another company that caters to large scale production needs is PCBWay. They offer a range of services including PCB fabrication, assembly, and testing. Their assembly services start from as low as $30 for 10 pieces of PCB assembly. They also offer a range of additional services such as PCB testing, SMT assembly, and stencil services.

In conclusion, there are several affordable PCB assembly services available for both small businesses and large scale production needs. It is important to consider factors such as pricing, quality, and additional services offered before selecting a service provider.

Future Trends in PCB Assembly

Automation and AI

As technology continues to advance, automation and AI are becoming increasingly prevalent in the field of PCB assembly. These tools allow for faster and more accurate assembly processes, reducing the need for human intervention and minimizing the risk of errors. With the use of automated equipment and AI algorithms, PCB assembly can be completed in a fraction of the time it would take with manual labor. This not only saves time but also reduces costs, making PCB assembly more affordable for consumers.

Advancements in Materials

Advancements in materials are also contributing to the future of PCB assembly. New materials are being developed that offer improved performance, durability, and flexibility. For example, flexible PCBs are becoming more popular due to their ability to bend and twist without breaking, making them ideal for use in wearable technology and other applications where flexibility is important. Additionally, materials such as graphene and carbon nanotubes are being explored for use in PCBs, as they offer superior conductivity and other desirable properties.

Overall, the future of PCB assembly looks bright as technology continues to advance and new materials are developed. With the use of automation and AI, as well as advancements in materials, PCB assembly is becoming faster, more accurate, and more affordable. As a result, consumers can expect to see more advanced and innovative PCB products in the years to come.

Regulatory Considerations

Environmental Regulations

When it comes to PCB assembly, there are several environmental regulations that must be taken into consideration. One of the most important regulations is the RoHS (Restriction of Hazardous Substances) directive, which restricts the use of hazardous materials in electronic products. This includes lead, mercury, cadmium, hexavalent chromium, and certain flame retardants.

In addition to RoHS, there are other environmental regulations that may apply to PCB assembly, such as the Waste Electrical and Electronic Equipment (WEEE) directive and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. It is important to ensure that all applicable regulations are being followed to avoid any penalties or legal issues.

Industry Certifications

In addition to environmental regulations, there are also industry certifications that may be required for PCB assembly. One such certification is the IPC-A-610, which is a standard for the acceptability of electronic assemblies. This certification ensures that the PCB assembly meets certain quality standards and is free from defects.

Other industry certifications that may be required include ISO 9001, which is a quality management system certification, and ISO 14001, which is an environmental management system certification. These certifications can help demonstrate to customers and stakeholders that the PCB assembly is of high quality and meets environmental standards.

Overall, it is important to consider both environmental regulations and industry certifications when it comes to PCB assembly. By following these regulations and obtaining the necessary certifications, PCB assemblers can ensure that their products are of high quality, safe, and environmentally friendly.