Colorado PCB Assembly Reviews: Top Companies for Quality and Reliability

Colorado PCB assembly reviews are an essential aspect of choosing the right company to handle your PCB manufacturing needs. PCB assembly involves the process of attaching electronic components to a printed circuit board. It is a critical process that requires expertise, precision, and attention to detail to ensure the final product meets the desired specifications.

Choosing the right PCB assembly company can be a daunting task, but with the right information, it can be a lot easier. Colorado has several PCB assembly companies, and finding the right one can be overwhelming. PCB assembly reviews provide valuable insights into the quality of services provided by different companies. By reading reviews, potential customers can get an idea of the company’s strengths and weaknesses, the quality of their products, and their level of customer service.

Overview of Colorado PCB Assembly Services

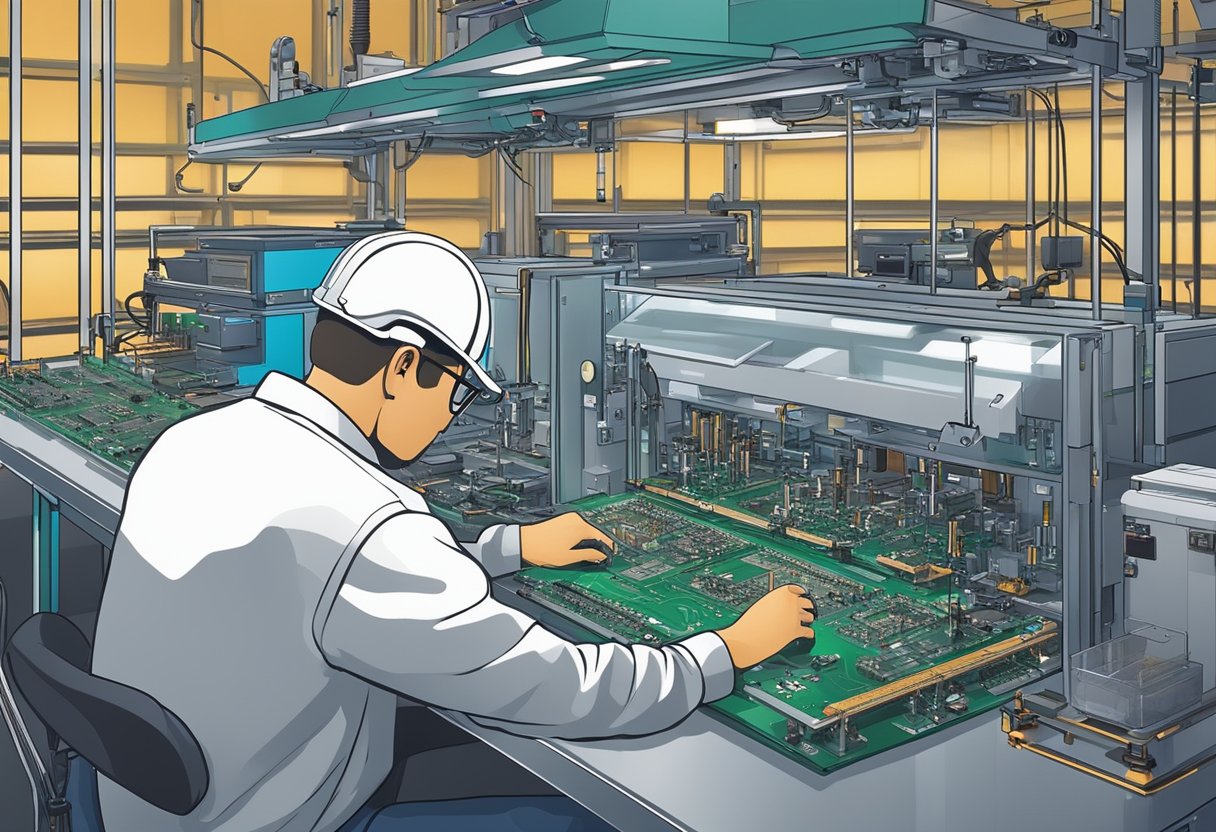

Colorado PCB Assembly is a reputable provider of PCB assembly services in Colorado. They offer a wide range of services to meet the needs of different clients. Their services include surface mount technology (SMT) assembly, through-hole assembly, mixed technology assembly, and more.

The company has a team of experienced professionals who are knowledgeable in the PCB assembly industry. They use advanced equipment and techniques to ensure that their clients receive high-quality services. Additionally, they have a quality control team that ensures that all products meet the required standards before delivery.

Colorado PCB Assembly provides flexible services to accommodate the needs of their clients. They offer quick turnaround times, low-volume production runs, and high-volume production runs. Their services are suitable for different industries, including aerospace, medical, automotive, and more.

The company values customer satisfaction and strives to provide excellent services to their clients. They offer competitive pricing and transparent communication throughout the assembly process. Clients can track the progress of their orders and receive regular updates from the company.

In summary, Colorado PCB Assembly is a reliable provider of PCB assembly services in Colorado. They have a team of experienced professionals, advanced equipment, and a commitment to customer satisfaction. Their flexible services and competitive pricing make them a preferred choice for clients in various industries.

Top-Rated PCB Assembly Companies in Colorado

Colorado is home to several top-rated PCB assembly companies that offer high-quality services to customers. These companies have been reviewed based on their reliability, quality of service, customer support, and pricing. Here are some of the top-rated PCB assembly companies in Colorado:

Company A Review

Company A is a leading PCB assembly company in Colorado that has been in business for several years. They offer a wide range of services, including PCB design, assembly, and testing. The company has a team of experienced professionals who use the latest technology and equipment to ensure that their customers receive high-quality services.

One of the things that make Company A stand out is their commitment to customer satisfaction. They work closely with their customers to understand their needs and provide customized solutions that meet their requirements. The company also offers competitive pricing, making them a top choice for customers on a budget.

Company B Review

Company B is another top-rated PCB assembly company in Colorado that has built a reputation for quality and reliability. They offer a range of services, including PCB design, assembly, and testing, as well as prototyping and production runs. The company has a team of skilled technicians who use the latest equipment and technology to deliver high-quality services.

One of the things that make Company B stand out is their attention to detail. They have a rigorous quality control process that ensures that every PCB they produce meets the highest standards. The company also offers excellent customer support, with a team of friendly and knowledgeable professionals who are always ready to help.

Company C Review

Company C is a trusted PCB assembly company in Colorado that has been in business for many years. They offer a range of services, including PCB design, assembly, and testing, as well as prototyping and production runs. The company has a team of experienced professionals who use the latest technology and equipment to deliver high-quality services.

One of the things that make Company C stand out is their focus on innovation. They are always looking for new ways to improve their processes and deliver better results to their customers. The company also offers competitive pricing, making them a top choice for customers on a budget.

In conclusion, Colorado is home to several top-rated PCB assembly companies that offer high-quality services to customers. Whether you are looking for PCB design, assembly, or testing services, these companies have the expertise and experience to meet your needs.

Quality Standards in PCB Assembly

ISO Certifications

Colorado PCB assembly companies take pride in their adherence to ISO standards. ISO 9001:2015 certification is a widely recognized standard for quality management systems. This certification ensures that the company has established processes and procedures to consistently provide products and services that meet customer and regulatory requirements. Additionally, ISO 13485:2016 certification is specific to medical device manufacturing, ensuring that the company meets the highest standards for quality in this critical industry.

IPC Compliance

IPC, the Association Connecting Electronics Industries, is a global trade organization that develops and publishes standards for the electronics industry. Colorado PCB assembly companies adhere to IPC standards to ensure high-quality products and services. IPC-A-610 is a widely recognized standard for electronic assemblies, and IPC-J-STD-001 is a standard for soldering processes. These standards ensure that the company follows best practices for manufacturing and assembly, resulting in reliable and high-quality products.

In addition to ISO and IPC standards, Colorado PCB assembly companies may also adhere to other standards specific to their industries. By ensuring compliance with these standards, companies can provide their customers with the confidence that their products are manufactured to the highest quality standards.

Customer Experiences with Colorado PCB Assembly

Testimonials

Colorado PCB Assembly has a reputation for delivering high-quality PCB assembly services to its customers. Many customers have shared their positive experiences with the company. One customer praised the company’s attention to detail and exceptional customer service. They said that the team at Colorado PCB Assembly was always available to answer their questions and provide updates on the progress of their project.

Another customer commended the company’s ability to meet tight deadlines. They said that they were impressed by the company’s quick turnaround time and the quality of the final product. The customer also appreciated the company’s competitive pricing.

Case Studies

Colorado PCB Assembly has worked with a variety of clients across different industries. The company has completed several successful projects that demonstrate its expertise in PCB assembly. One case study involves a medical device manufacturer that needed a reliable partner for their PCB assembly needs. Colorado PCB Assembly was able to provide a custom solution that met the manufacturer’s requirements and delivered the final product on time.

Another case study involves a startup that needed help with their PCB design and assembly. Colorado PCB Assembly worked closely with the startup’s team to develop a custom solution that met their unique needs. The startup was able to launch their product successfully, thanks in part to the quality of the PCB assembly provided by Colorado PCB Assembly.

Overall, Colorado PCB Assembly has a track record of delivering high-quality PCB assembly services to its customers. The company’s attention to detail, quick turnaround time, and competitive pricing make it a reliable partner for businesses in need of PCB assembly services.

Cost Analysis of PCB Assembly in Colorado

When it comes to PCB assembly, one of the most important factors to consider is the cost. Colorado has a number of PCB assembly companies that offer competitive pricing and high-quality services. However, the cost of PCB assembly in Colorado can vary depending on a number of factors.

One of the main factors that can affect the cost of PCB assembly in Colorado is the complexity of the project. More complex projects require more time and resources, which can drive up the cost. Additionally, the size of the project can also affect the cost. Larger projects may require more materials and labor, which can increase the overall cost.

Another factor that can impact the cost of PCB assembly in Colorado is the type of components used. Higher quality components may cost more, but they can also improve the reliability and performance of the final product. It is important to weigh the cost of the components against their benefits to determine the best option for your project.

The location of the PCB assembly company can also affect the cost. Companies located in more expensive areas may have higher overhead costs, which can be reflected in their pricing. However, it is important to consider the overall quality of the company’s services and the benefits of working with a local company.

Overall, the cost of PCB assembly in Colorado can vary depending on a number of factors. It is important to carefully consider these factors when choosing a PCB assembly company and to work with a company that offers competitive pricing and high-quality services.

Turnaround Times for PCB Projects

When it comes to PCB assembly, turnaround times are crucial. Colorado PCB assembly reviews show that customers value quick turnaround times and expect their projects to be completed on time. In the highly competitive PCB assembly industry, companies that can deliver fast turnaround times are more likely to win and retain customers.

One of the factors that affect turnaround times is the complexity of the project. More complex projects may require more time to complete, especially if they involve custom components or unique designs. However, experienced PCB assembly companies have the expertise and resources to handle even the most complex projects efficiently.

Another factor that affects turnaround times is the availability of components. If a component is out of stock or on backorder, it can delay the entire project. However, reputable PCB assembly companies have established relationships with suppliers and can source components quickly and efficiently.

To ensure fast turnaround times, PCB assembly companies use various strategies, such as optimizing their production processes, using advanced equipment and software, and implementing quality control measures. They also have dedicated teams that focus on project management and customer service, ensuring that projects are completed on time and to the customer’s satisfaction.

In conclusion, turnaround times are a critical factor in PCB assembly, and customers expect their projects to be completed quickly and efficiently. Experienced and reputable PCB assembly companies have the expertise, resources, and strategies to deliver fast turnaround times and meet customer expectations.

Technical Capabilities in Colorado PCB Assembly

Advanced Assembly Techniques

Colorado PCB assembly companies have a reputation for utilizing advanced assembly techniques to produce high-quality printed circuit boards. These techniques include surface mount technology (SMT), through-hole technology (THT), and mixed technology. SMT is a widely used technique that involves placing components directly onto the surface of the board, while THT involves inserting components through holes in the board. Mixed technology combines both SMT and THT to achieve the best of both worlds.

In addition to these techniques, Colorado PCB assembly companies also employ advanced testing and inspection methods to ensure that each board meets the highest standards of quality. These methods include automated optical inspection (AOI), X-ray inspection, and functional testing. With these techniques, Colorado PCB assembly companies can produce boards that are reliable and efficient.

Component Sourcing

Another advantage of Colorado PCB assembly companies is their ability to source high-quality components from reputable suppliers. They have established relationships with suppliers that provide them with the best components at competitive prices. This ensures that the boards they produce are of the highest quality and meet the specific requirements of their clients.

Moreover, Colorado PCB assembly companies have experience working with a wide range of components, including surface mount devices (SMDs), ball grid arrays (BGAs), and microcontrollers. They have the expertise to handle complex designs and can provide custom solutions to meet the unique needs of their clients.

In conclusion, Colorado PCB assembly companies have the technical capabilities to produce high-quality printed circuit boards using advanced assembly techniques and high-quality components. With their experience and expertise, they can provide custom solutions to meet the specific needs of their clients.

Design for Manufacturability (DFM) Advice

Design for Manufacturability (DFM) is a critical aspect of PCB assembly that ensures the efficient and cost-effective production of high-quality circuit boards. By optimizing the design of the PCB, manufacturers can reduce the risk of defects and improve the overall quality of the final product.

Here are some DFM advice that PCB designers should keep in mind:

- Simplify the Design: A simple design is always better than a complex one. By reducing the number of components and the complexity of the circuit, designers can minimize the risk of errors and improve the manufacturability of the board.

- Use Standard Components: Standard components are readily available and are less expensive than custom ones. Designers should use standard components whenever possible to reduce the cost of the PCB.

- Avoid Over-Reliance on SMT: Surface Mount Technology (SMT) is a popular assembly method, but it is not suitable for all components. Designers should avoid over-reliance on SMT and consider through-hole components for high-power or high-voltage circuits.

- Minimize the Number of Layers: The number of layers in a PCB affects the cost of manufacturing. Designers should aim to minimize the number of layers required for their design to reduce the cost of the PCB.

- Use Design Rules: Design rules are guidelines that ensure the manufacturability of the PCB. Designers should use design rules to ensure that their PCBs meet the manufacturer’s requirements.

By following these DFM advice, PCB designers can optimize their designs for efficient and cost-effective manufacturing.

Post-Assembly Support Services

When choosing a PCB assembly company, it’s important to consider the post-assembly support services they offer. This can include troubleshooting, repairs, and rework. Here’s a closer look at these services:

Troubleshooting

Even with the most careful assembly, issues can arise with PCBs. A good assembly company will offer troubleshooting services to help identify the root cause of any problems. This may involve reviewing schematics, testing components, and analyzing data.

The company should have experienced technicians who can quickly diagnose and resolve any issues. They should also have the necessary equipment and tools to perform thorough testing and analysis.

Repairs and Rework

If a problem is found during testing, repairs or rework may be necessary. A reputable assembly company will have skilled technicians who can perform these tasks quickly and efficiently.

Repairs may involve replacing faulty components, while rework may involve changing the layout or design of the PCB. The company should have the necessary equipment and tools to perform these tasks, as well as the expertise to ensure the PCB functions as intended.

Overall, post-assembly support services are an important consideration when choosing a PCB assembly company. Look for a company with experienced technicians, thorough testing and analysis capabilities, and the ability to perform repairs and rework as needed.

Environmental Standards and Compliance

Colorado PCB Assembly takes environmental standards and compliance very seriously. The company is committed to reducing its environmental impact by implementing sustainable practices throughout its operations.

One way Colorado PCB Assembly ensures environmental compliance is by adhering to regulations set by the Environmental Protection Agency (EPA) and the Restriction of Hazardous Substances (RoHS) directive. The company ensures that its products are free from hazardous substances such as lead, mercury, cadmium, and hexavalent chromium.

In addition, Colorado PCB Assembly has implemented a waste reduction program that includes recycling and reusing materials wherever possible. The company also uses energy-efficient lighting and equipment to reduce energy consumption and minimize its carbon footprint.

Overall, Colorado PCB Assembly’s commitment to environmental standards and compliance is a testament to its dedication to sustainability and responsible business practices.

Future Trends in PCB Assembly and Manufacturing

As technology continues to advance, so does the world of PCB assembly and manufacturing. There are several trends that are expected to shape the future of this industry.

Miniaturization

One of the most significant trends in PCB assembly and manufacturing is the continued push towards miniaturization. As devices become smaller and smaller, the need for smaller and more complex PCBs increases. This trend has led to the development of new manufacturing techniques, such as microvia drilling and laser drilling, which allow for smaller and more precise PCBs.

Automation

Another trend in PCB assembly and manufacturing is the increased use of automation. With the rise of Industry 4.0, more and more manufacturers are turning to automation to increase efficiency and reduce costs. Automated assembly lines can perform tasks such as pick-and-place, soldering, and inspection faster and more accurately than human workers.

Green Manufacturing

Environmental concerns are also driving changes in PCB assembly and manufacturing. Many manufacturers are now focusing on green manufacturing practices, such as the use of lead-free solder, RoHS-compliant materials, and energy-efficient processes. These practices not only reduce the environmental impact of manufacturing but also improve the quality of the final product.

3D Printing

Finally, 3D printing is also expected to have a significant impact on the future of PCB assembly and manufacturing. While 3D printing is still in its early stages for PCBs, it has the potential to revolutionize the industry by allowing for the rapid prototyping and production of complex PCBs.

Overall, the future of PCB assembly and manufacturing looks bright, with new technologies and practices driving innovation and efficiency. As the industry continues to evolve, manufacturers will need to stay up-to-date with the latest trends and adapt to meet the changing needs of their customers.