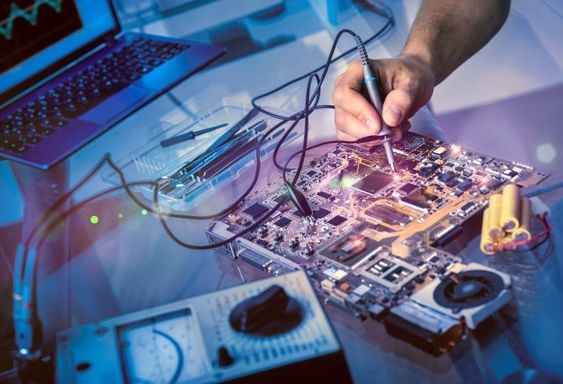

Best PCB Design Service: Winow One-Stop PCB Solution

Today’s fast-paced technological landscape requires industries to cut costs while minimizing the loss of quality. One way to achieve this balance is through optimizing Printed Circuit Board (PCB) designs. PCBs are integral components in a wide range of electronic devices, and the design process plays a pivotal role in determining manufacturing and component costs. Winow, a leader in providing PCB design services, has developed strategies and tips for optimizing PCB designs so that you can reduce costs while ensuring high-quality standards.

PCB Design Miniaturization: Shrinking the World of Electronics

As electronic devices become more integrated into our daily lives, the demand for smaller, more compact components has never been higher. PCB design services are at the forefront of this trend, driving innovations in miniaturization.

Winow understands the importance of size in modern electronics and offers solutions for compact and highly efficient PCB designs. With advancements in surface mount technology (SMT), Winow’s PCB design services enable the creation of smaller, lightweight, and power-efficient electronic products. From smartphones to IoT devices, Winow’s commitment to miniaturization is transforming the electronics landscape.

Best PCB Design Service: Optimizing PCB Design for Cost Efficiency — Tips and Strategies

Before diving into cost optimization strategies, it’s crucial to recognize the significance of PCB design in the manufacturing process. PCBs serve as the foundation for electronic devices, connecting and supporting various components. A well-designed PCB not only ensures proper functionality but also impacts manufacturing efficiency and material costs.

1. Collaborative Design Approach

To begin the cost optimization process, it’s essential to foster collaboration between PCB designers, engineers, and manufacturers. Winow’s PCB design services emphasize open communication and collaboration to identify potential cost-saving opportunities early in the design phase.

2. Component Selection and Standardization

Careful consideration of component selection can significantly impact manufacturing costs. When possible, opt for standardized components readily available in the market. Standardized components are typically more affordable, and their availability ensures a smoother supply chain.

3. PCB Design Service: Size and Layout Optimization

PCB size and layout can have a substantial impact on material costs. Minimizing the board’s size and utilizing efficient component placement can reduce the amount of material required. Winow’s PCB design services prioritize efficient layouts to maximize cost savings.

4. Design for Manufacturability (DFM)

Designing with manufacturability in mind is crucial for cost optimization. Utilize Design for Manufacturability (DFM) guidelines to simplify the manufacturing process. Minimize complex routing and avoid designs that require specialized fabrication techniques, as these can significantly increase manufacturing costs.

5. Thermal Management

Effective thermal management is essential to ensure the reliability of electronic components. Carefully consider heat dissipation and thermal distribution in your PCB design. Properly designed thermal solutions can prevent overheating issues, ultimately reducing maintenance and replacement costs.

6. Prototyping and Testing

Investing in prototypes and thorough testing is a proactive approach to cost optimization. Identifying and addressing design flaws early can prevent costly rework during the manufacturing phase. Winow’s PCB design services offer comprehensive prototyping and testing to ensure designs meet quality and cost targets.

7. Material Selection

Selecting the right materials can lead to substantial cost savings. Consider the application’s requirements and choose materials that meet performance standards while minimizing costs. Winow’s experts can guide you in selecting cost-effective yet high-quality materials.

8. Design for Longevity

Electronic devices often have long lifecycles. Designing PCBs with durability and longevity in mind can reduce replacement and maintenance costs over the product’s lifespan. Winow’s design services prioritize reliability and longevity as key factors in cost optimization.

9. Environmental Considerations

Sustainability and environmental compliance are increasingly important in today’s market. Designing PCBs with eco-friendly materials and manufacturing processes can not only reduce costs through material efficiency but also appeal to environmentally-conscious consumers.

Best PCB Design Service: Design for Manufacturing (DFM)

1. Streamlining the Production Process

DFM is a critical aspect of PCB design, and Winow understands this well. Their experienced team of designers prioritizes DFM principles from the very beginning of the design process. By doing so, they ensure that the final PCB design is not only functional but also optimized for manufacturing efficiency.

2. PCB Design Service: Materials Selection

Winow starts by selecting materials that are readily available and cost-effective while meeting the project’s specifications. This proactive approach helps minimize lead times and production costs, resulting in quicker time-to-market for their clients.

3. Component Placement and Trace Routing

Efficient component placement and trace routing are vital for DFM. Winow’s designers are experts in minimizing signal interference, reducing crosstalk, and ensuring adequate heat dissipation. This approach reduces the likelihood of errors during production and testing, ultimately enhancing product reliability.

Best PCB Design Service: Design for Assembly (DFA)

1. Facilitating Efficient Assembly

DFA is another key consideration in PCB design, and Winow seamlessly integrates these principles into its services. DFA focuses on optimizing the assembly process, reducing labor costs, and improving the overall efficiency of PCB manufacturing.

2. PCB Design Service: Component Selection and Packaging

Winow’s designers carefully select components with readily available packages, simplifying the assembly process. They also consider component orientation, making it easier for assembly line workers to place and solder components accurately.

3. SMT vs. Through-Hole Technology

Depending on the project’s requirements, Winow advises clients on the most suitable technology. Surface Mount Technology (SMT) is often preferred due to its efficiency and space-saving advantages, but through-hole technology may be chosen for specialized applications. Winow’s expertise ensures that the right choice is made.

4. PCB Design Service: Design Review and Prototyping

Before finalizing the PCB design, Winow conducts thorough design reviews and may create prototypes for testing and validation. This step allows for the identification and rectification of any potential assembly issues, reducing costly redesigns and production delays.

Conclusion

In conclusion, optimizing PCB designs for cost efficiency is a multifaceted process that requires careful consideration of various factors. Manufacturers like Winow specialize in offering PCB design services that prioritize cost-effective solutions without compromising quality. By adopting collaborative design approaches, component standardization, size optimization, DFM principles, and other strategies, industries can reduce manufacturing and component costs while maintaining high-quality standards. This approach not only benefits the bottom line but also enhances competitiveness in a rapidly evolving industry.