High Quality PCB Assembly: Tips and Tricks for Maximum Efficiency!

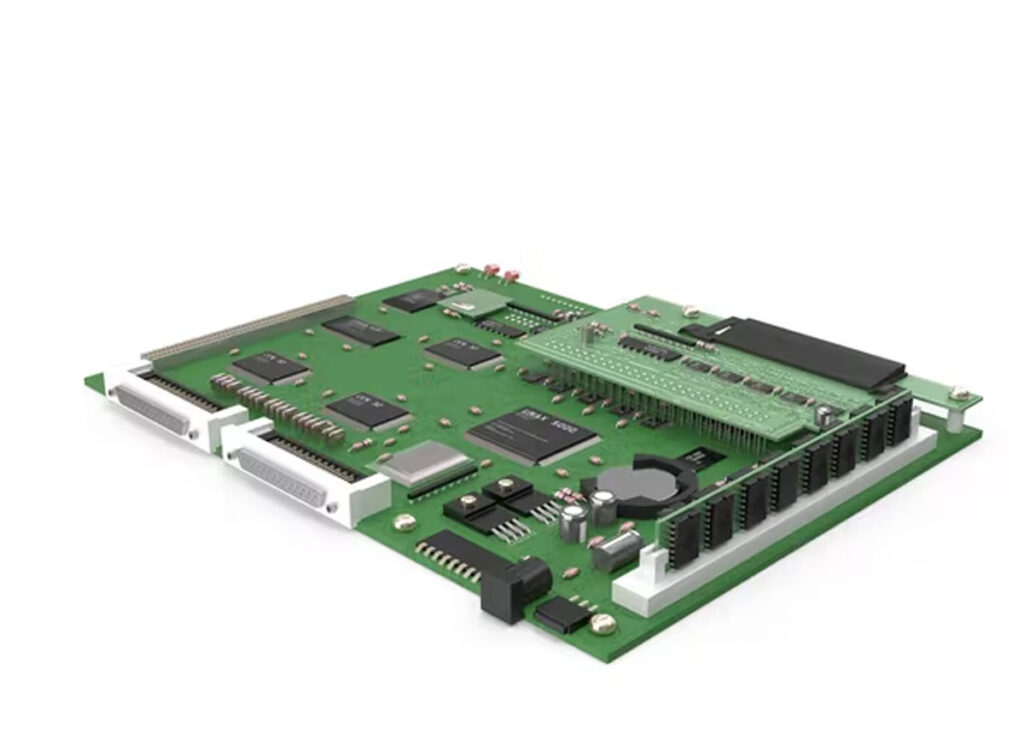

Printed circuit boards (PCBs) are the backbone of modern electronics. They are used in a wide range of applications, from consumer electronics to aerospace and medical devices. As such, it is essential to ensure that PCBs are assembled with the highest quality standards in order to ensure their reliability and performance. In this blog post, we will discuss the basics of high quality PCB assembly, the benefits of achieving high quality standards, key components of a successful assembly process, tips and tricks for maximum efficiency, design considerations, tools and materials, quality control and inspection, troubleshooting common issues, and quality and regulatory compliance.

What is a High Quality PCB Assembly?

High quality PCB assembly is the process of building a printed circuit board with the highest levels of quality, reliability, and performance. This process involves selecting the correct components, designing the layout, assembling the components to the board, soldering all the connections, and then testing the finished product for any potential issues. The goal of high quality PCB assembly is to ensure that the end product is reliable and performs to the desired specifications.

The process of assembling a PCB is a complex one and can be broken down into several key steps. Firstly, the components need to be chosen and organized in a way that will ensure that they fit on the board and function as expected. This includes selecting the right components, designing the circuit layout, and testing the board for any potential issues. Secondly, the components need to be assembled onto the board and soldered into place. This requires a high level of skill and attention to detail to ensure that all the connections are correct. Lastly, the board needs to be tested to ensure that it functions as expected.

The process of high quality PCB assembly is critical for the reliability and performance of the end product. It can be a time consuming and complex process, but the end result is a product that is reliable and performs to the highest standards.

The Benefits of High Quality PCB Assembly

The benefits of high quality PCB assembly are numerous. Firstly, by ensuring that all the components are correctly assembled and soldered, it ensures that the board will perform as expected. This is especially important when dealing with sensitive components that are prone to damage or failure. Secondly, high quality assembly also ensures that all the connections are secure and reliable. This prevents any potential issues caused by loose connections or faulty soldering, which can lead to costly repairs or replacements. Finally, high quality PCB assembly also ensures that the board meets all the relevant regulatory standards, which is especially important for medical and aerospace applications.

The benefits of high quality PCB assembly are clear, and the process is essential for ensuring the reliability and performance of the end product.

Key Components of High Quality PCB Assembly

The key components of high quality PCB assembly are the components, the design, the assembly process, and the testing. Firstly, the components need to be chosen carefully to ensure that they are compatible with the board and will function as expected. Secondly, the design of the circuit layout needs to be carefully planned in order to ensure that all the components fit on the board and that all the connections are secure. Thirdly, the assembly process needs to be carefully executed in order to ensure that all the components are correctly soldered and that no loose connections are present. Finally, the board needs to be tested to ensure that it performs as expected.

These components are essential for ensuring that the board is assembled with the highest levels of quality and reliability.

Tips and Tricks for Maximizing Efficiency

There are several tips and tricks that can be employed to ensure that the assembly process is as efficient as possible. Firstly, it is important to ensure that all the components are organized in a way that makes the assembly process easier. This can be done by carefully planning the layout of the board, grouping components together, and labeling all the components. Secondly, it is important to ensure that the soldering process is efficient and effective. This can be done by using the correct tools and techniques, such as flux, desolder braid, and soldering iron. Finally, it is important to ensure that the board is tested for any potential issues prior to the final assembly. This can be done by performing functional tests and visual inspections.

By following these tips and tricks, you can ensure that the assembly process is as efficient as possible.

Design Considerations for High Quality PCB Assembly

When designing a PCB for high quality assembly, there are several key considerations that need to be taken into account. Firstly, the layout of the board needs to be carefully planned in order to ensure that all the components fit on the board and that all the connections are secure. Secondly, the components need to be chosen carefully to ensure that they are compatible with the board and will function as expected. Thirdly, it is important to ensure that the board is designed to meet all the relevant regulatory standards, which is especially important for medical and aerospace applications. Finally, it is important to ensure that the board is designed in a way that facilitates the assembly process and makes it as efficient as possible.

By taking these design considerations into account, you can ensure that the board is designed for high quality assembly.

Tools and Materials for Quality PCB Assembly

When assembling a PCB, it is important to have the right tools and materials in order to ensure that the assembly process is efficient and effective. Firstly, it is important to have the correct tools for soldering, such as a soldering iron, flux, desolder braid, and a hot air rework station. Secondly, it is important to have the correct materials, such as solder paste, solder wire, and thermal interface materials. Finally, it is important to have the right tools for testing, such as a multimeter and an oscilloscope.

Having the right tools and materials is essential for ensuring that the assembly process is successful and efficient.

Quality Control and Inspection

Once the board has been assembled, it is important to perform quality control and inspection in order to ensure that the board is functioning as expected. This can be done by performing a series of tests, such as functional tests, visual inspections, and measurements. It is also important to ensure that the board meets all the relevant regulatory standards, which is especially important for medical and aerospace applications.

Quality control and inspection are essential for ensuring that the board is functioning as expected and meets all the relevant standards.

Troubleshooting Common PCB Assembly Issues

When assembling a PCB, it is important to be aware of common issues that can arise. This includes incorrect component placement, incorrect soldering, and incorrect testing. It is important to be aware of these issues and to take steps to prevent them. If any issues do arise, it is important to troubleshoot them quickly and effectively in order to ensure that the board is functioning as expected.

By being aware of common issues and troubleshooting them quickly, you can ensure that the board is functioning correctly.

Quality and Regulatory Compliance

The final step in the PCB assembly process is ensuring that the board meets all the relevant regulatory standards. This is especially important for medical and aerospace applications, as these products need to meet stringent safety and quality standards. It is important to ensure that the board meets all the relevant standards, as failure to do so can lead to costly repairs and replacements.

Quality and regulatory compliance are essential for ensuring that the board meets all the relevant standards.

Conclusion

High quality PCB assembly is essential for ensuring the reliability and performance of the end product. The process involves selecting the right components, designing a layout, assembling the components, soldering all the connections, and then testing the finished product. It is important to ensure that all the components are chosen and organized in a way that will ensure that they fit on the board and function as expected. It is also important to ensure that the board is designed to meet all the relevant regulatory standards. By following these tips and tricks, you can ensure that your PCB is assembled with the highest levels of quality and reliability.