All You Need to Know About Contract PCB Assembly Factory

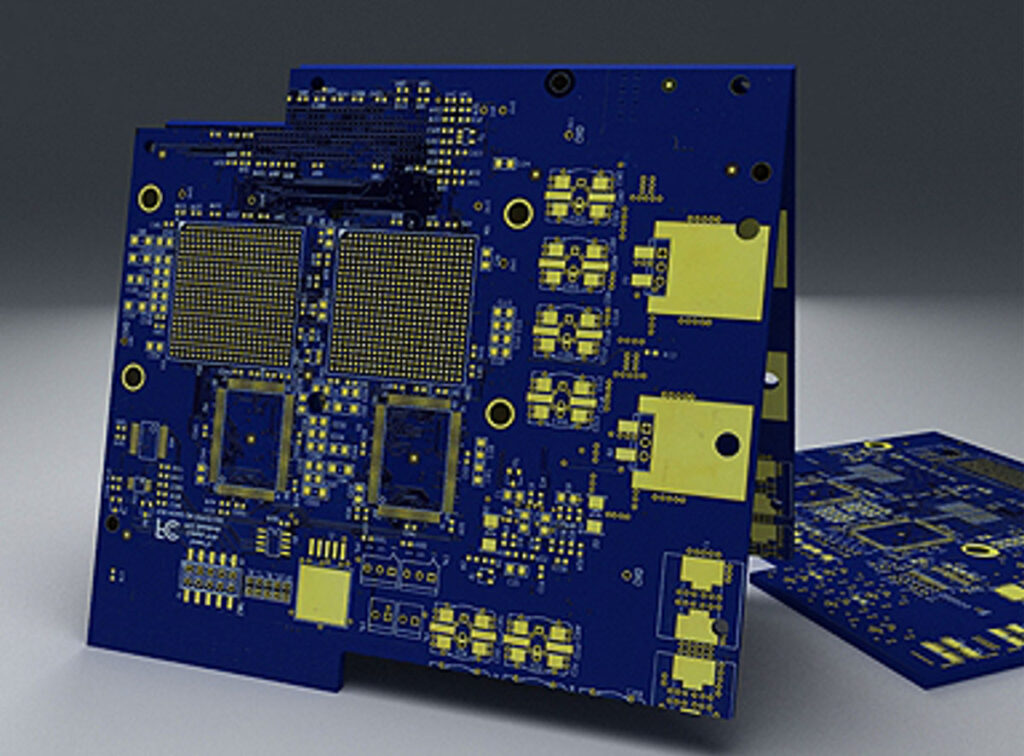

A contract PCB assembly factory is a manufacturing facility that specializes in providing PCB assembly services to other companies on a contract basis. These factories typically have the necessary equipment, personnel, and expertise to handle all aspects of PCB assembly, including surface mount technology (SMT), through-hole technology, and testing.

Companies that use contract PCB assembly factories typically provide the necessary components and the PCB design, and the contract factory takes care of the assembly process and ships the completed PCBs back to the company. This allows the companies to outsource the PCB assembly process, so they can focus on other aspects of their business, such as design and marketing.

Contract PCB assembly factories can be found all over the world, and many of them have certifications such as ISO 9001, IPC-A-610, and UL, which indicates that they meet international quality standards.

Are you looking for a reliable source to have your PCB boards manufactured? From prototypes to mass production, contract PCB assembly factories are the ideal solution for any PCB manufacturing needs. In this blog post, we will explore what contract PCB assembly factories are, the benefits of using one, key components, different types, quality control, tips for choosing the right one, what to look for, common challenges, and how to find the right fit for you.

What is Contract PCB Assembly Factory?

A contract PCB assembly factory is a third party that manufactures printed circuit boards (PCBs) on behalf of a customer. They are responsible for designing and assembling the PCBs, as well as providing the necessary components. Contract PCB assembly factories offer a wide range of services, from prototype to mass production.

Contract PCB assembly factories are highly skilled and experienced in the PCB manufacturing industry. They are well-versed in the latest technologies and trends, and have the ability to produce complex designs quickly and accurately. Furthermore, they have the capability to handle any volume of orders, from small-scale prototypes to large-scale mass production.

Benefits of Working With Contract PCB Assembly Factory

There are many benefits to working with a contract PCB assembly factory. Firstly, they offer competitive pricing for both small and large orders. This means that you can get the best value for your money. Secondly, they are experienced and knowledgeable in the industry, so they can provide the best advice and guidance when it comes to designing and manufacturing PCBs.

Furthermore, they have the necessary equipment and resources to handle any volume of orders, from prototype to mass production. They also have the capability to meet tight deadlines and produce high-quality products.

Finally, contract PCB assembly factories provide excellent customer service. They are always willing to go the extra mile to ensure customer satisfaction.

Key Components of Contract PCB Assembly Factory

Contract PCB assembly factories are equipped with the latest technologies and resources to provide the best services. Some of the key components of contract PCB assembly factories include:

- Designing software: This software is used to design the PCBs according to the customer’s specifications. It also helps to ensure that the design is accurate and reliable.

- Automated assembly equipment: This equipment is used to assemble the components of the PCBs. It helps to ensure that the PCBs are manufactured accurately and quickly.

- Testing equipment: This equipment is used to test the PCBs for any errors or defects. It helps to ensure that the products are of high quality.

- Quality control: Quality control is an important part of the contract PCB assembly process. The contract PCB assembly factory will have a team of experts who will inspect the products to ensure that they meet the customer’s requirements.

Different Types of Contract PCB Assembly Factory

Contract PCB assembly factories come in different sizes and types. Depending on your needs, you can choose from small-scale, medium-scale, or large-scale factories. Each type of factory has its own set of advantages and disadvantages.

Small-scale factories are ideal for small-scale projects or prototypes. They are cost-effective and can be completed quickly. However, they may not be able to handle large orders or complex designs.

Medium-scale factories are suitable for mid-size projects. They are more expensive than small-scale factories but can handle more complex designs and larger orders.

Large-scale factories are suitable for large-scale projects. They are the most expensive option but can handle any volume of orders and complex designs.

Quality Control in Contract PCB Assembly Factory

Quality control is an important part of the contract PCB assembly process. The contract PCB assembly factory will have a team of experts to inspect the products to ensure that they meet the customer’s requirements. They will also use advanced testing equipment to test the PCBs for any errors or defects.

The contract PCB assembly factory will also follow strict quality control procedures. This includes inspecting the components, testing the PCBs, and conducting a final inspection before the products are shipped. This helps to ensure that the products are of the highest quality and meet the customer’s expectations.

Tips for Choosing the Right Contract PCB Assembly Factory

When choosing a contract PCB assembly factory, it is important to consider several factors. Here are some tips for choosing the right one:

- Research different factories and compare their services, capabilities, and prices.

- Make sure that the factory has experience in the type of products you need.

- Check their customer service and support.

- Ask for references and read reviews.

- Make sure that the factory is ISO certified and follows quality control procedures.

What to Look for When Selecting a Contract PCB Assembly Factory

When selecting a contract PCB assembly factory, there are a few things to look for. First, you should consider their experience in the industry, as well as their capabilities and resources. Secondly, you should check their customer service, as well as their quality control procedures. Finally, you should ask for references and read reviews before making a decision.

Common Challenges of Working with Contract PCB Assembly Factory

Working with a contract PCB assembly factory can be challenging. Some of the common challenges include:

- Miscommunication: Miscommunication between the customer and the factory can lead to delays and errors.

- Quality control: Quality control is an important part of the contract PCB assembly process. It is essential that the contract PCB assembly factory follows strict quality control procedures to ensure that the products are of the highest quality.

- Cost: Contract PCB assembly factories can be expensive, especially for high-volume orders. It is important to compare prices and services to make sure that you get the best value for your money.

Finding the Right Contract PCB Assembly Factory for You

Finding the right contract PCB assembly factory for your needs can be a daunting task. It is important to do your research and compare different factories to find the right one for you. Make sure to consider their experience, capabilities, customer service, and quality control procedures before making a decision.

Conclusion

Contract PCB assembly factories are the ideal solution for any PCB manufacturing needs. They offer competitive pricing for both small and large orders, have the necessary resources and capabilities to handle any volume of orders, and provide excellent customer service. It is important to consider their experience, capabilities, customer service, and quality control procedures before making a decision. With the right contract PCB assembly factory, you can have the best products manufactured quickly and accurately.

If you are looking for a reliable contract PCB assembly factory for your needs, feel free to contact us for a free quote. We have the experience, resources, and capabilities to handle any volume of orders, from small-scale prototypes to large-scale mass production. Our team of experts will work closely with you to ensure that your PCBs are manufactured to the highest quality.

CTA: Contact us today for a free quote and let us help you find the best contract PCB assembly factory for your needs!