What Is PCB And FPC And Why Do You Need To Know About Them

A PCB (printed circuit board) is a board made of insulating material (typically fiberglass or plastic) that has conductive pathways etched onto its surface. These pathways are used to connect electronic components together and create a functioning circuit. PCBs are used in a wide range of electronic devices, including computers, smartphones, and appliances.

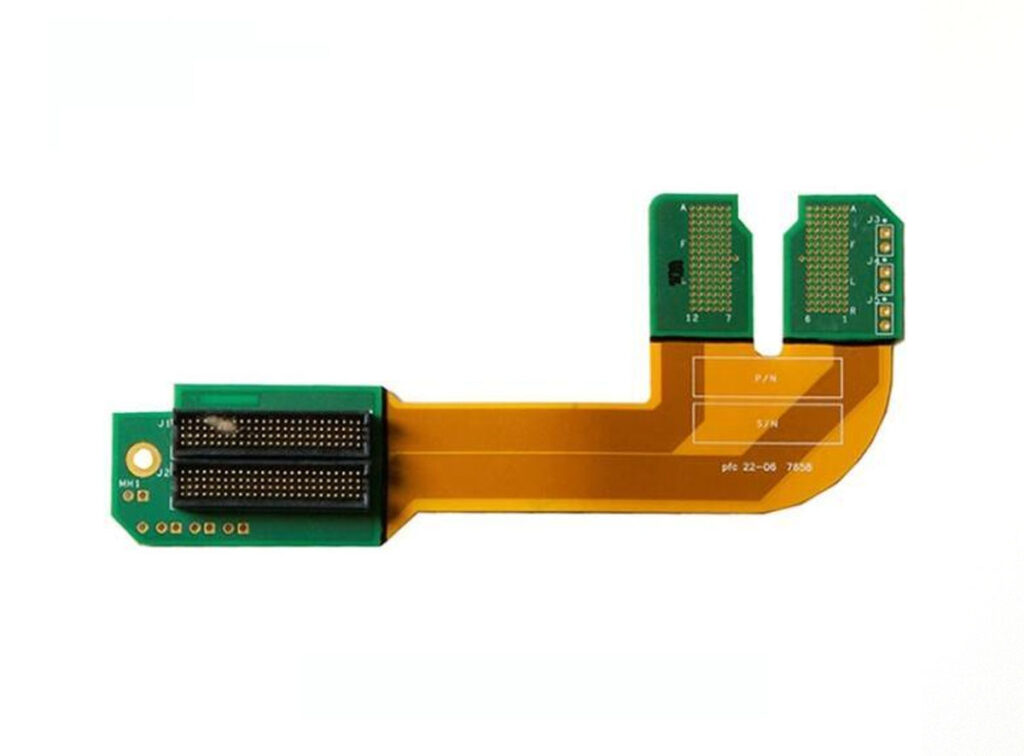

FPC (flexible printed circuit) also known as Flex PCB, is a type of PCB that is made from a flexible material, such as polyimide or polyester, that can bend and flex without breaking. This makes FPCs useful for applications where traditional PCBs would be too stiff or brittle, such as in portable devices and electronic devices that need to be folded or bent. FPCs also typically have a much thinner profile than traditional PCBs, which makes them useful for devices that need to be as small and lightweight as possible.

What Is PCB And FPC?

Are you wondering what is PCB and FPC? Today let’s talk about them. PCB (printed circuit board) and FPC (flexible printed circuit) are two types of boards that are used in the electronics industry. These boards can be used in different ways, depending on the need of the application. PCBs are used for creating multi-layer boards, while FPCs are usually single-sided boards with a circuit pattern on one side.

Printed Circuit Board (PCB)

A PCB is a piece of material with copper traces on it so that electricity can flow through it. The copper traces are connected to pads at each end, which can be soldered together to form connections between components and other parts of the circuit. The copper traces themselves are not connected to anything but each other, so they form an electrical path through the board when they’re connected together with solder or conductive adhesives like silver paint or epoxy.

Flexible Printed Circuit Boards (FPCs)

Flexible printed circuit boards (FPCs) are similar to rigid PCBs except they are bendable like a sheet of paper and can be folded into multiple layers. FPCs are often used in portable devices because they are lightweight and flexible enough to fit into small spaces.

The Basics Technology Of PCB And FPC

Do you know what is PCB and FPC? PCB is an abbreviation for Printed Circuit Board, which is a board used in electronics and electrical applications. This board is made up of multiple layers of materials that are laminated together to form the base material for circuit boards.

FPC (Flexible Printed Circuit) is a technology allowing the production of flexible PCBs. It differs from the traditional rigid printed circuit boards in that it allows the manufacturing of circuits flexible enough to be bent, rolled, or folded and still function properly.

The copper traces on a PCB can be fabricated using different methods:

- 1) Through-hole technology – Used for high-density connections between components like resistors, capacitors, inductors, etc.

- 2) Surface mount technology – Used for high-density connections between components mounted on the surface of a circuit board such as power transistors, diodes, etc.

- 3) Wire bonding – Used for connecting integrated circuits to each other or to external wires or leads.

- 4) Microstrip technology – Used for transmitting signals from one point to another through dielectric waveguides.

- 5) Microvia technology – A combination of microstrip and wire bond.

There are several types of FPC technologies available:

- 1) Thermoplastic FPC (TFC)

- 2) Thermoset FPC (TFK)

- 3) Laminated FPC (LFC)

PCB & FPC: Why Should You Care?

PCB and FPC are the two most commonly used printed circuit board materials. They both are made of high-quality materials and feature good electrical properties. However, their main difference is in how they are made.

While FPCs are made from polymer sheets that have been laminated together and then etched to create traces and pads, PCBs are made from a base material such as fiberglass or epoxy mixed with copper ink. This allows them to be much thinner than FPCs while still being very durable.

Both PCBs and FPCs can be used in many different industries, but they each have their own specific uses depending on what you need them for.

PCB VS FPC: The Differences Between Them

PCB and FPC are two types of flexible circuit boards, which are used for different purposes.

While PCB is a rigid board, FPC is a thin flexible board.

PCB stands for Printed Circuit Board whereas FPC stands for Flexible Printed Circuit.

PCB was invented in 1959 by IBM. IBM used it for the first time in the 1960s to make computers more compact, reliable, and easier to maintain.

FPC was invented in the 1990s when manufacturers started using it as an alternative to PCB because it was cheaper than PCB and could be easily bent or folded into any shape without breaking or cracking it.

FPCs are thinner than PCBs and they can be bent around curves easily because they are made up of copper-clad laminate layers which act as insulation between layers of copper foil.

The most commonly used thicknesses of PCBs are 1oz, 2oz, 4oz, etc., while FPCs come in different thickness ranges as well like 0.1mm-0.3mm, etc., but they cannot be thicker than 3mm because they will become too stiff and rigid.

PCB VS FPC: How To Choose Between The Two?

PCB and FPC are two popular types of flexible printed circuit boards (PCB). Both PCBs are thin and flexible, but they have different applications and advantages.

FPC is a type of PCB that is made from FR-4 glass epoxy laminate material. FR-4 is the most common material for making PCBs due to its high-temperature resistance and low cost.

FPCs are typically used in the industrial sector where they are exposed to high temperatures or other harsh environments. They can be used in the military, aerospace, and automotive industries as well as medical devices.

PCBs are made from copper foil laminated onto a non-conductive substrate such as fiberglass cloth or epoxy resin-impregnated paper. They can withstand extreme temperatures and may be used in environments where there is a risk of shock or vibration.

A PCB can be assembled by hand or automatically by machine, while FPCs are usually hand-assembled because they cannot be soldered with standard soldering equipment due to their flexibility.

As a PCB & FPC manufacturer, WINOW can provide high-quality products according to your requirements.

Conclusion

In short, FPC is a more flexible and high-quality alternative to PCB. They both serve the same basic purpose (being a circuit board to build electronics on). With Trusted Prototype PCB Assembly Manufacturer—WINOW, you can buy the available products for your business.