Unlock the Potential of Printed Circuit Board Assembly!

Are you curious about what printed circuit board assembly (PCBA) is and how it can benefit your business? In this blog post, we will explore the basics of PCBA and the advantages of using it for your projects. We’ll also discuss the design considerations and equipment needed for successful PCBA, as well as the different types of assemblies available. Finally, we’ll discuss the advantages of outsourcing your PCBA needs. Read on to learn more about the potential of PCBA and how to unlock it for your business.

What is a Printed Circuit Board Assembly?

A printed circuit board assembly (PCBA) is a kind of electronic device that is composed of multiple components, including circuit boards, components, and connectors, all of which are connected to form a functioning electrical system. The components are encased in a protective material, such as a plastic housing, to protect them from the environment and to provide insulation. The components and boards are also connected with wires, which are insulated and soldered to keep them in place.

The PCBA is used to control and manage the various electrical and electronic components that make up a system or device. It is a versatile tool, as it can be used to control a variety of electronic devices, including computers, smartphones, televisions, and medical equipment. The PCBA is also used for industrial applications, such as robotics and automation.

Benefits of Printed Circuit Board Assembly

The use of PCBA offers several advantages for businesses and individuals alike. First, it helps reduce costs by reducing the need for separate components and wiring. This reduces the time and labor costs associated with assembling the components and wiring them together. Additionally, PCBA can help reduce the size of a product, as all components are integrated into one device. This can help manufacturers save on space and cost.

Another benefit of PCBA is that it increases reliability. By using a PCBA, manufacturers can ensure that the components used in their product are of the highest quality, which increases the reliability of the product. Additionally, PCBA helps reduce the risk of failure, as all components are integrated into one device and there is less chance of a problem occurring.

Finally, PCBA also helps reduce the amount of time needed to manufacture a product. By reducing the number of components that need to be assembled and wired, the overall process is sped up, allowing manufacturers to produce more products in less time.

Printed Circuit Board Assembly Process

The printed circuit board assembly process includes several steps, including design, fabrication, assembly, and testing. During the design stage, the components are designed and the layout of the board is determined. This ensures that the board is able to meet the needs of the device being produced.

During the fabrication stage, the components and boards are created. This includes printing the circuit traces onto the board, attaching components to the board, soldering the components, and testing the board.

The assembly stage involves connecting the components and boards together in the correct order. This can be done manually or with automated machinery. After the assembly is complete, the board is tested to ensure that it is working correctly.

Finally, the testing and troubleshooting stage is used to verify that the board is functioning correctly. This includes testing the board for any errors, as well as troubleshooting any problems that may arise.

Printed Circuit Board Assembly Components

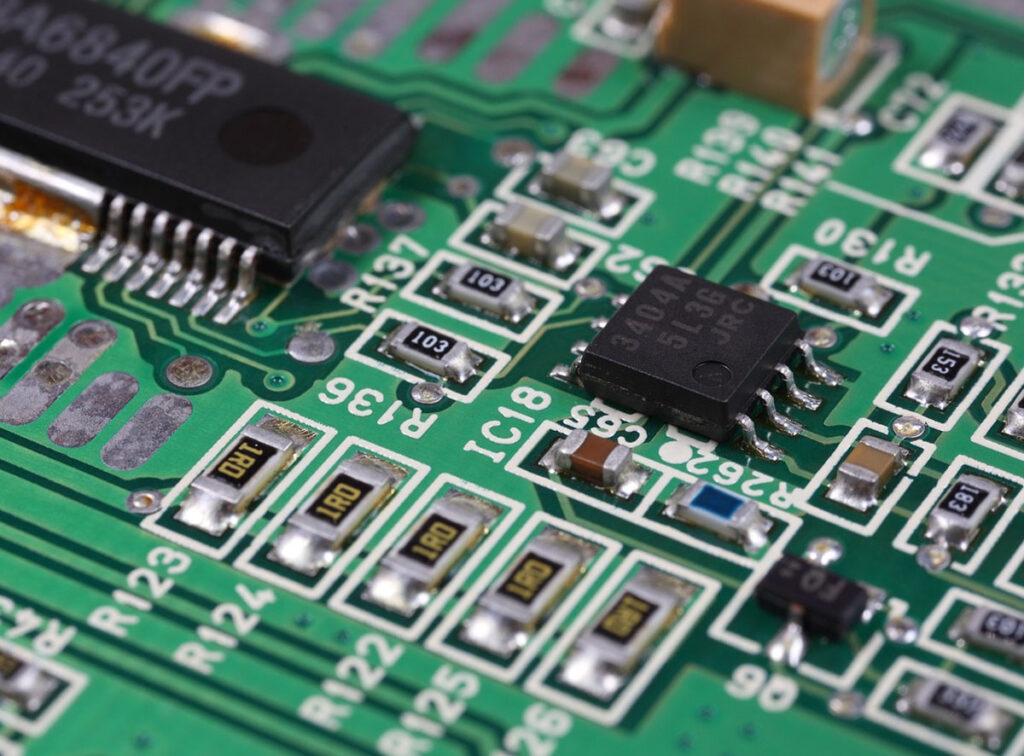

The components used in PCBA include circuit boards, components, and connectors. The circuit boards are what hold the components in place, while the components and connectors are used to connect the boards and components together.

The components used in PCBA can vary depending on the type of device being assembled. Common components include resistors, capacitors, transistors, diodes, connectors, and switches. Additionally, the components used in PCBA can also vary depending on the type of device being assembled. For example, the components used in a computer will be different from the components used in a smartphone.

Printed Circuit Board Assembly Design Considerations

When designing a PCBA, there are several design considerations that must be taken into account. This includes the size of the board, the type of components used, the layout of the board, and the type of connectors used. Additionally, the components and boards must be designed in a way that ensures that they are able to withstand the device’s environment and meet the device’s requirements.

The size of the board is important, as it determines how much space the components and boards will take up. Additionally, the size of the board will affect the cost of the board and the complexity of the design.

The layout of the board is also important, as it determines how the components and boards are connected. Additionally, the layout must ensure that the components and boards are able to fit together and that the board is able to meet the device’s requirements.

Finally, the type of components and connectors used must be taken into account. Different types of components and connectors are better suited to different types of devices. Additionally, the components and connectors must be able to withstand the environment and meet the device’s requirements.

Printed Circuit Board Assembly Tools and Equipment

The tools and equipment used in PCBA include soldering irons, soldering stations, and hot-air stations. Additionally, other tools such as wire cutters, strippers, and tweezers are also used.

The soldering iron is used to attach components to the board, while the soldering station is used to hold the components and boards in place while they are being soldered. The hot-air station is used to solder components that are difficult to access with the soldering iron.

The wire cutters and strippers are used to cut and strip the wires used to connect the components and boards. The tweezers are used to pick up and place components on the board.

Printed Circuit Board Assembly Testing and Troubleshooting

Testing and troubleshooting are important parts of the PCBA process. Testing is used to verify that the board is functioning correctly, while troubleshooting is used to identify and fix any problems that may arise.

Testing involves running tests on the board to ensure that it is functioning correctly. This includes checking for any errors, as well as testing the board’s performance. Additionally, the board can be tested for any potential issues that could arise during operation.

Troubleshooting is used to identify and fix any problems that may be occurring. This includes checking the board for any errors and checking the components and boards for any problems. Additionally, troubleshooting can be used to identify and fix any potential issues that could arise during operation.

Different Types of Printed Circuit Board Assemblies

There are several different types of PCBA available, including single-sided, double-sided, and multilayered boards. Single-sided boards are the simplest type of PCBA and are used for basic applications. Double-sided boards are more complex and are used for more advanced applications. Multilayered boards are the most complex type of PCBA and are used for more sophisticated applications.

The type of PCBA used will depend on the device being assembled and the requirements of the device. Single-sided boards are typically used for simple devices, while double-sided and multilayered boards are used for more complex devices.

What Are the Advantages of Outsourcing Printed Circuit Board Assembly?

Outsourcing your PCBA needs can offer several advantages. First, outsourcing can help reduce costs, as the cost of outsourcing is typically lower than the cost of producing the components and boards yourself. Additionally, outsourcing can also help reduce the amount of time needed to produce the product, as the components and boards are already assembled and tested.

Outsourcing can also help improve the quality of the product, as the components and boards are usually of higher quality than those produced in-house. Additionally, outsourcing can help reduce the risk of errors and defects, as the components and boards have already been tested and verified.

Conclusion

As you can see, printed circuit board assemblies can offer several advantages for businesses and individuals alike. They can help reduce costs, increase reliability, and speed up the manufacturing process. Additionally, they also offer design considerations and tools and equipment needed for successful PCBA. Finally, outsourcing your PCBA needs can help reduce costs, improve quality, and reduce the risk of errors and defects. If you’re looking to unlock the potential of PCBA, consider outsourcing your needs and taking advantage of all that PCBA has to offer.