Revolutionizing Your PCB Camera Assembly – Here’s How

PCB camera assembly is the process of designing, manufacturing, and assembling printed circuit boards (PCBs) with cameras. It’s a complex task, but it’s also a critical component of many modern devices. In this blog, we’ll explore the different aspects of PCB camera assembly, from the benefits of modern processes to the latest developments, and how to troubleshoot common issues. By the end, you’ll know how to revolutionize your PCB camera assembly process and get the most out of your end products.

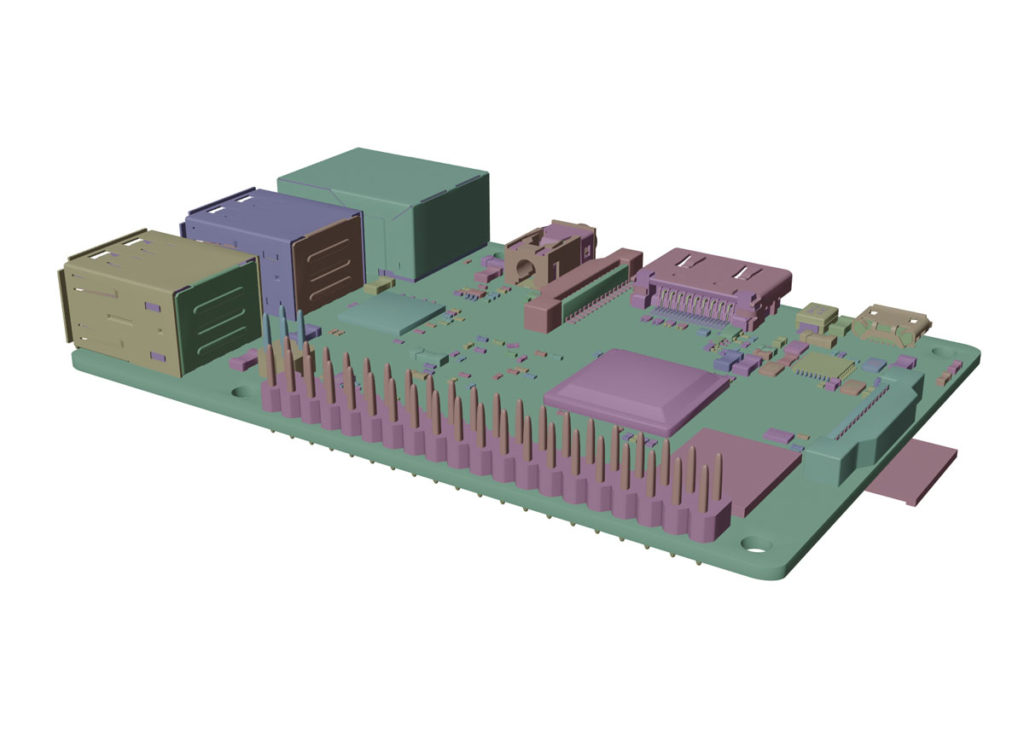

Introduction to PCB Camera Assembly

PCB camera assembly is a complex process that requires a combination of manual and automated steps. In this process, a PCB is designed with camera components and then manufactured. This involves forming holes for the camera components, connecting the components with traces, and soldering the components into place. The PCB and the camera components are then tested and assembled into the final product.

PCB camera assembly is used in a variety of products, from consumer electronics to medical devices. It is an essential component of many products, as it allows the product to capture images and videos. As such, it’s important to get the assembly process right in order to ensure the quality of the end product.

Benefits of Modern PCB Camera Assembly

Modern PCB camera assembly processes offer a number of benefits compared to traditional processes. First, they are more reliable and accurate, as they use automated processes to ensure the components are placed and soldered correctly. This reduces the risk of errors and improves the overall quality of the end product.

Second, modern processes are faster and more cost-effective than traditional processes. Automated processes reduce the time needed for assembly, and the cost of materials is also reduced. This makes it easier for manufacturers to produce products quickly and at a lower cost.

Third, modern processes are also more flexible. They can be used to create complex designs with multiple cameras, which can be used for a variety of applications. This allows manufacturers to create products with advanced features and capabilities.

Finally, modern processes are also more eco-friendly. Automated processes use less energy, and they produce less waste. This helps to reduce the environmental impact of PCB camera assembly.

Advantages of Using Automated PCB Camera Assembly

Automated PCB camera assembly is the use of robots and other automated machines to perform the assembly process. This offers a number of advantages compared to manual processes.

First, automated processes are more efficient and accurate. They can be programmed to precisely place and solder components, which reduces the risk of errors and improves the quality of the end product.

Second, automated processes are also faster than manual processes. They can complete the assembly process in a fraction of the time, which reduces the time needed for production.

Third, automated processes are also more consistent. They can perform the same assembly process over and over again without any variation, which ensures that each product is identical.

Finally, automated processes are also more cost-effective. They reduce the need for manual labor, which lowers the cost of production.

The Latest Developments in PCB Camera Assembly

The PCB camera assembly process has come a long way in recent years. Thanks to advances in technology, manufacturers can now create more complex designs with multiple cameras, and they can also use automated processes to reduce production times and costs.

The latest developments in PCB camera assembly include the use of 3D printing for the initial design and manufacturing process. This allows manufacturers to quickly and accurately create complex designs with multiple cameras. In addition, manufacturers can also use automated processes to reduce the time needed for assembly and the cost of materials.

Another development is the use of artificial intelligence (AI) for the assembly process. AI-powered robots can be programmed to precisely place and solder components, which reduces the risk of errors and improves the accuracy of the end product. AI can also be used to optimize the production process, which further reduces production times and costs.

How to Choose the Right PCB Camera Assembly Process

When choosing a PCB camera assembly process, it’s important to consider a number of factors. First, you should consider the complexity of the design and the number of cameras needed. This will determine whether you need to use a manual or automated process.

Second, you should also consider the cost of materials. Automated processes require specialized equipment and materials, which can increase the cost of production. However, this cost is usually offset by the efficiency and accuracy of the process.

Third, you should also consider the time needed for assembly. Manual processes can take a long time, especially for complex designs with multiple cameras. Automated processes, on the other hand, are much faster and can reduce the time needed for assembly.

Finally, you should also consider the environmental impact of the process. Automated processes use less energy and produce less waste, which can help to reduce the environmental impact of production.

How to Design a PCB Camera Assembly Process

Once you have chosen the right PCB camera assembly process, the next step is to design the process. This involves determining the steps needed to complete the assembly process, as well as the materials and equipment needed.

First, you should determine the steps needed to complete the process. This includes designing the PCB, manufacturing the components, connecting the components, and testing the product. You should also consider the safety measures needed to protect workers and the environment.

Second, you should also determine the materials and equipment needed. This includes the PCB, camera components, soldering tools, and testing equipment. You should also consider the type of materials used, as this will determine the cost and environmental impact of production.

Third, you should also determine the process flow. This involves determining the sequence of steps needed to complete the process. This is important for ensuring that each step is completed correctly and in the right order.

Finally, you should also consider the automation options available. Automated processes can reduce the time needed for assembly and the cost of materials, but they require specialized equipment and materials. You should consider whether automation is worth the additional cost.

Tips for Optimizing Your PCB Camera Assembly Process

Once you have designed your PCB camera assembly process, it’s time to optimize it. Here are some tips for optimizing your process:

First, use the right tools and materials. This includes using the right soldering tools and materials, such as lead-free solder, to ensure the highest quality end product.

Second, use automated processes whenever possible. Automated processes can reduce the time needed for assembly and the cost of materials. They can also reduce the risk of errors and improve the accuracy of the end product.

Third, use quality assurance measures to ensure the quality of the end product. This includes testing the product after each step of the assembly process and ensuring that each component is placed and soldered correctly.

Fourth, use data to monitor and optimize the process. This includes collecting data on production times, errors, and materials used. This data can then be used to identify areas for improvement and optimize the process.

Finally, use preventive maintenance measures to reduce the risk of errors and improve the quality of the end product. This includes cleaning and inspecting the equipment regularly, as well as replacing worn out components.

Common Challenges with PCB Camera Assembly

PCB camera assembly can be a challenging process, and there are a number of common challenges that manufacturers may face.

First, the complexity of the design can make the process difficult. Complex designs with multiple cameras require precise placement of components, which can be difficult to achieve with manual processes. Automated processes can reduce the risk of errors, but they require specialized equipment and materials.

Second, the cost of materials can be a challenge. Automated processes require specialized materials, which can increase the cost of production. However, this cost is usually offset by the efficiency and accuracy of the process.

Third, the time needed for assembly can be a challenge. Manual processes can take a long time, especially for complex designs with multiple cameras. Automated processes can reduce the time needed for assembly, but they require specialized equipment and materials.

Finally, the environmental impact of the process can be a challenge. Automated processes use less energy and produce less waste, but they require specialized materials.

How to Troubleshoot Your PCB Camera Assembly Process

If you experience any issues with your PCB camera assembly process, there are a few steps you can take to troubleshoot the issue.

First, you should check the design of the PCB. Make sure that the components are placed and soldered correctly, and ensure that the traces are connected properly.

Second, you should check the materials and equipment used for the process. Make sure that the materials are of good quality and that the equipment is in good condition.

Third, you should check the process flow. Make sure that each step is completed correctly and in the right order.

Fourth, you should check the automation options available. Make sure that the automated processes are working correctly and that they are producing the desired results.

Finally, you should also check the data collected from the process. This data can be used to identify areas for improvement and optimize the process.

Conclusion

PCB camera assembly is a complex process that requires a combination of manual and automated steps. Modern processes offer a number of benefits compared to traditional processes, such as increased efficiency and accuracy, faster production times, and reduced costs. In addition, modern processes also offer more flexibility, as they can be used to create complex designs with multiple cameras.

When designing your PCB camera assembly process, it’s important to consider a number of factors, such as the complexity of the design, the cost of materials, and the time needed for assembly. It’s also important to optimize the process by using the right tools and materials, using automated processes whenever possible, and using quality assurance measures to ensure the quality of the end product. Finally, it’s important to troubleshoot any issues that may arise during the process in order to ensure the quality of the end product.

By following these tips, you can revolutionize your PCB camera assembly process and get the most out of your end products. Whether you’re designing a consumer electronics product or a medical device, you can be sure that your PCB camera assembly process is up to date and efficient.

CTA: Ready to revolutionize your PCB camera assembly process? Contact us today to learn more!